Operating instructions, Service instruction – Bell & Gossett A07258B Check-Trol Flange User Manual

Page 2

TABLE 1

Pressure – Temperature Ratings

Melting Range

Working Temperature

Maximum Working Gauge Pressure

Joining

Degrees

Degrees

Size

1

⁄

8

" – 1"

Size 1

1

⁄

4

" – 2"

Size 2

1

⁄

2

" – 4"

Material

°F

°C

°F

°C

psi

kPa

psi

kPa

psi

kPa

95-tin-antimony

0/+100

-18/+38

500*

3500*

400*

2800*

300*

2100*

solder

450/464

230/240

0/+150

-18/+66

400*

2800*

350*

2400*

275*

2000*

ASTM B32 alloy

0/+200

-18/+93

300*

2100*

250*

1700*

200

1400

grade 95TA

0/+250

-18/+121

200

1400

175

1200

150

1050

Note: Above stated limits are not imposed by the valve, but by the strength of the soldering joint according to ASME B16.22.

*Soldered copper tube joints have been tested at 230 psi (1600 kPa) in accordance with ISO 2016.

.

.

d) While soldering, it is important to use a properly sized torch with a

sharp pointed flame so that the solder end is heated fully and quickly.

Apply heat so that the flame is directed on the cup area but away

from the valve body. Although soft 50/50 solder is easier to use,

these valves can also be successfully soldered with 95-5, however

caution must be used to prevent damage (see table 1.) Cool the

valve body before soldering the second end.

e) Check the soldered connections for leaks.

OPERATING INSTRUCTIONS

To isolate the circulator from the system, turn the handle of both isola-

tion valves clockwise 90° to close the valve. Remove circulator for

repair/replacement.

IMPORTANT: Relieve pressure from the circulator by slowly loosening

the bolts allowing the water to slowly drain from the pump body. Refer

to the circulator instruction manual when reinstalling a circulator. After

a pump is reinstalled, turn the handle of both isolation valves counter-

clockwise 90° to open the valves for normal operation.

SERVICE INSTRUCTION

There is no service required for the Isolation or Check-Trol™ flanges.

CAUTION: Heat associated with the use of silver solder may

damage valve and void the warranty. Do not use silver sol-

der. Failure to follow these instructions could result in property dam-

age and/or moderate personal injury.

CAUTION: Corrosion or leakage of the valves can cause

damage or injury. Periodically inspect the valves for signs of

leakage or corrosion. If corrosion or leakage is noted, the valves must

be replaced. Failure to follow these instructions could result in prop-

erty damage and/or moderate personal injury.

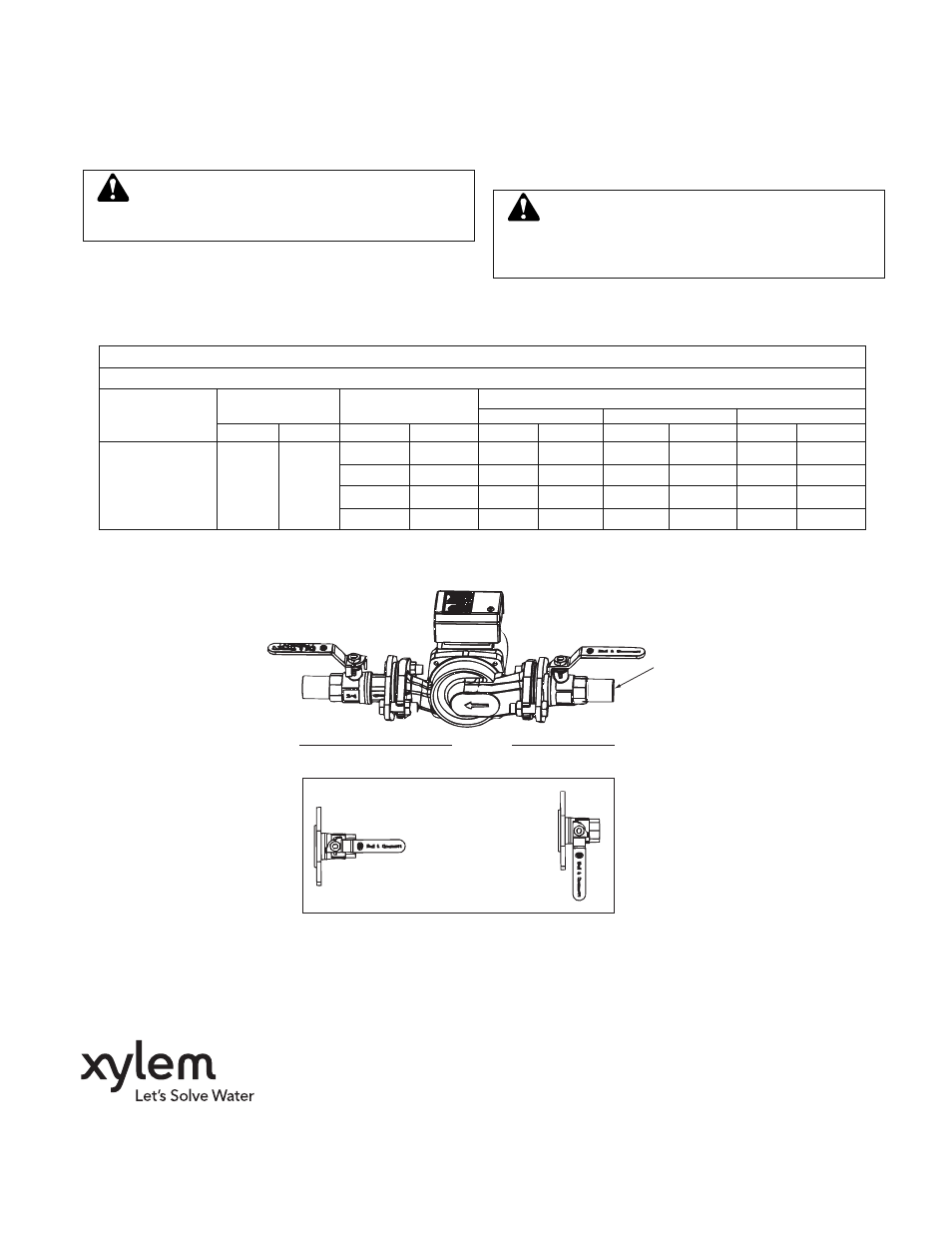

DISCHARGE SIDE

USE CHECK-TROL

TM

FLANGE

SUCTION SIDE

USE ISOLATION FLANGE

STANDARD

PIPING

VALVE OPEN

NORMAL OPERATION

VALVE CLOSED

FOR SERVICING

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. A07258B May 2012