Application information, Al5801 – Diodes AL5801 User Manual

Page 7

AL5801

Document number: DS35555 Rev. 3 - 2

7 of 11

July 2012

© Diodes Incorporated

AL5801

Application Information

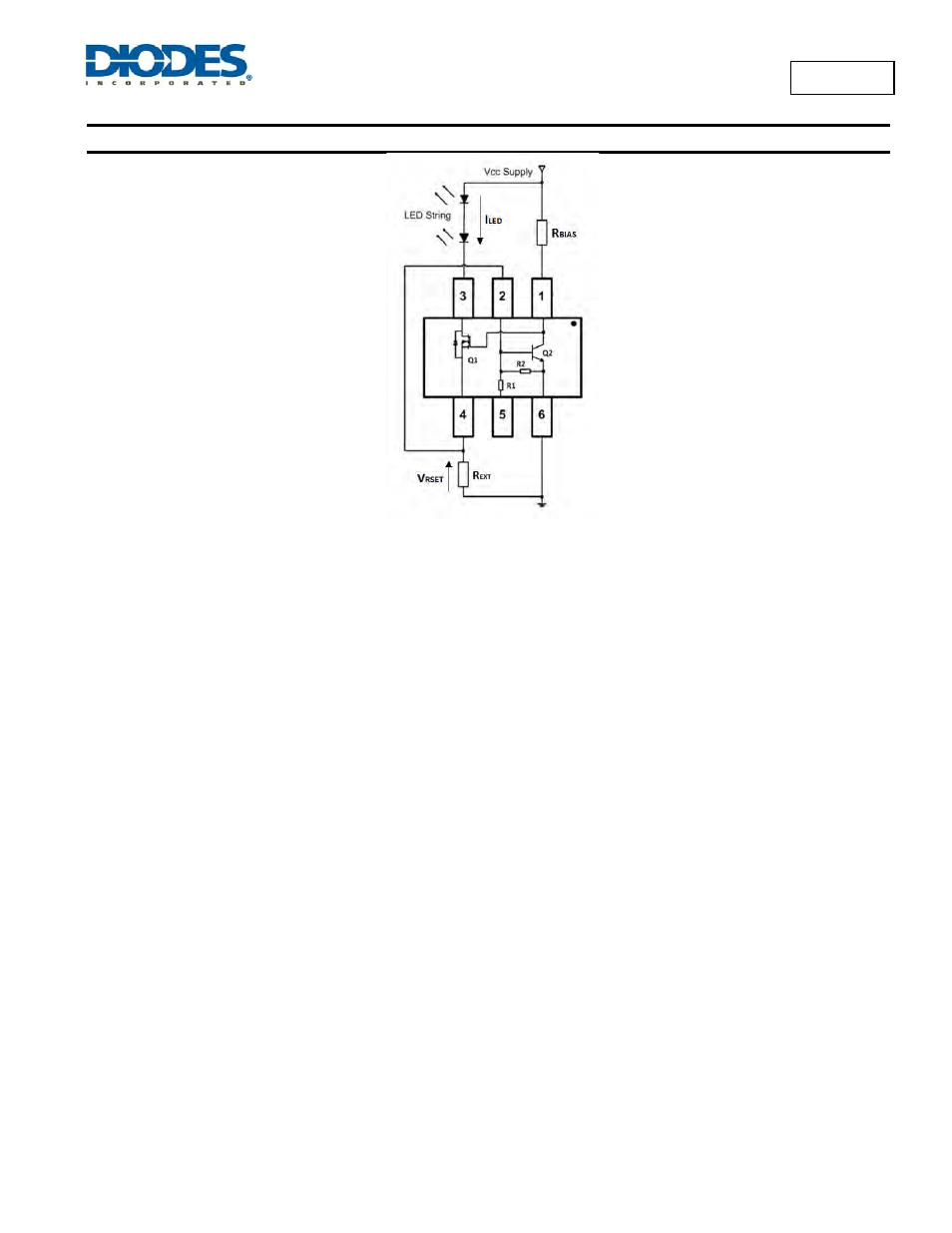

Figure 13 Typical Application Circuit for

Linear Mode Current Sink LED Driver

The AL5801 is designed for driving high brightness LEDs with typical LED current up to 350mA. It provides a more cost effective way for driving

low current LEDs when compared against more complex switching regulator solutions. Furthermore, it reduces the PCB board area of the

solution because there is no need for external components like inductors, capacitors and/or switching diodes.

Figure 13 shows a typical application circuit diagram for driving an LED or a string of LEDs. The NPN transistor Q2 measures the LED current by

sensing the voltage across an external resistor R

EXT

. Q2 uses its V

BE

as reference to set the voltage across R

EXT

and controls the gate voltage of

MOSFET Q1. Q1 operates in linear mode to regulate the LED current. The LED current is:

I

LED

= V

RSET

/ R

EXT

where V

RSET

is the V

BE

of Q2. V

BE

is 0.56V typical at a +25°C device temperature. See Figure 11 for the variation of V

BE

with Q2’s junction

temperature at I

BIAS

= 0.1mA. V

BE

has a negative temperature coefficient which reduces the LED current as the device warms up, protecting the

LED(s).

R

BIAS

should be chosen to drive 0.1mA current into the BIAS pin

R

BIAS

= ( V

CC

– 3.75V ) / 0.1mA

From the above equation, for any required LED current the necessary external resistor R

EXT

can be calculated from

R

EXT

= V

RSET

/ I

LED

The expected linear mode power dissipation must be factored into the design consideration. The power dissipation across the device can be

calculated by taking the maximum supply voltage less the minimum voltage across the LED string.

V

DS(Q1)

= V

CC(max)

– V

LED(min)

– V

RSET

P

D

= V

DS(Q1)

* I

LED

As the output LED current of AL5801 increases so will its power dissipation. The power dissipation will cause the device temperature to rise

above ambient,

T

A

, by an amount determined by the package thermal resistance, R

θJA

.

Therefore, the power dissipation supported by the device is dependent upon the PCB board material, the copper area and the ambient

temperature. The maximum dissipation the device can handle is given by:

P

D

= ( T

J(MAX)

- T

A

) / R

θJA

T

J(MAX)

= +

150°C

is the maximum device junction temperature. Refer to the thermal characteristic graphs in Figure 2 to 4 for selecting the

appropriate PCB copper area. Figure 12 shows the current capabilities of the AL5801 at +

25°C

with different PCB copper area heat sinks.