2 troubleshooting, 1 operator troubleshooting, Operational checks – Armasight NSGSPARK01CCIC1 Spark-G Night Vision Goggles User Manual

Page 28: After checking procedures

28

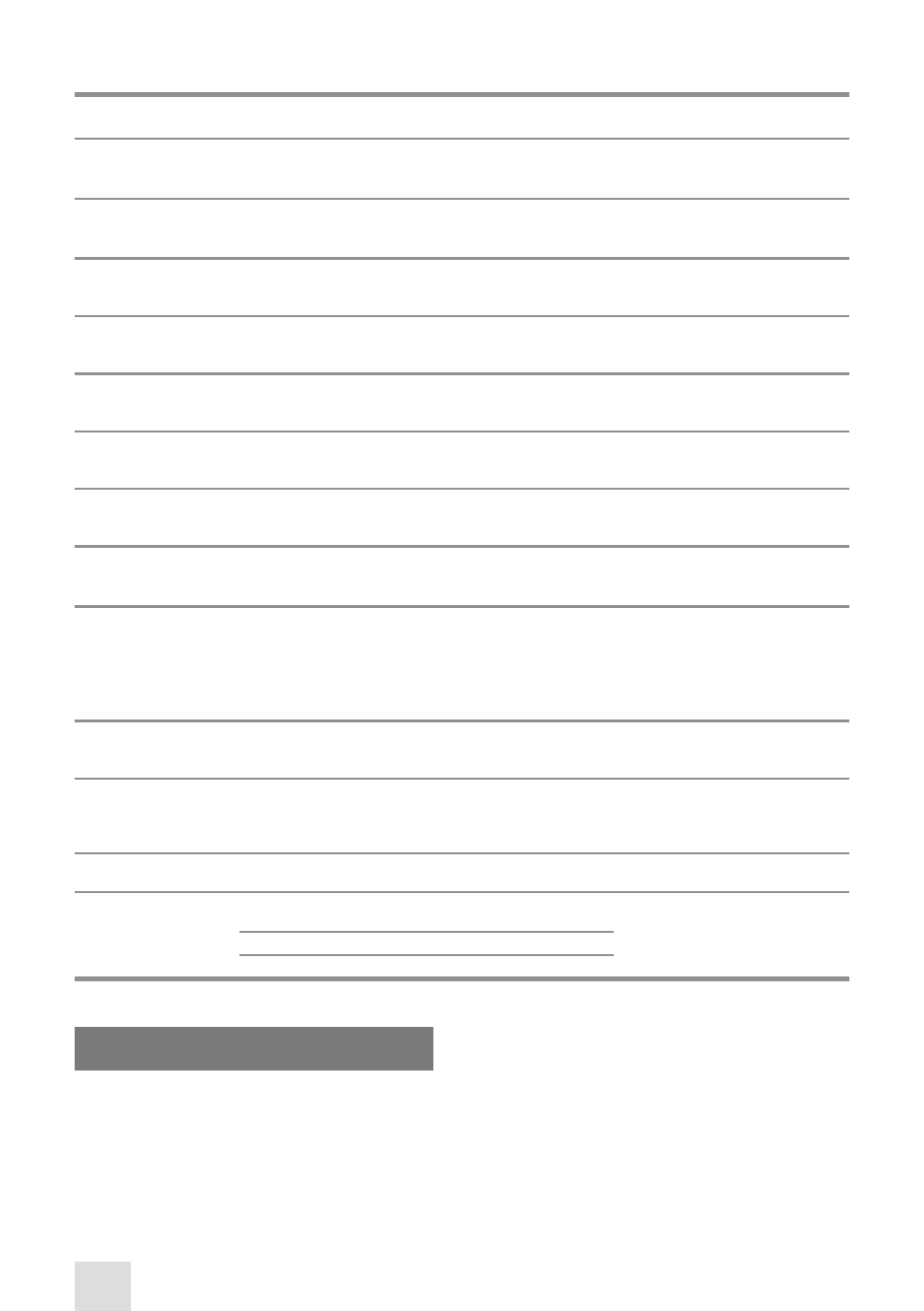

SEq

NO.

LOCATION ITEM TO

CHECK/SERVICE

PROCEDURE

NOT FULLY MISSION

CAPABLE IF

4

Lens Cap

Inspect for cracked, torn, or missing lens caps.

Cap is torn or cut.

Cup is not secured to the housing

of the lens.

5

Eyecup

Inspect for dirt, dust. Inspect for cracked or torn, bent, bro-

ken or improperly fitting eyecup.

If necessary, clean as per Para 4.4.2.

Cup torn or cut.

6

Battery

Compartment/

Cap

Verify that the battery cap is present. Inspect for corrosion,

moisture, corroded or defective contacts. Verify that the o-

ring is present.

Cap is missing, contacts damaged

or corroded, or o-ring is missing.

7

Function Switch

Check the switch for operation (without a battery).

Switch has no definite stopping

points. Switch knob is broken or

missing.

8

Lenses

Inspect optical surfaces for dirt, fingerprint residue, scratch-

es, chips, or cracks.

Scratches or chips hinder vision

with Spark turned on. Cracks are

present.

9

Focusing Ring

Rotate the focusing ring to ensure free movement (range is

approximately 1/3 turn).

Ring gets stuck or adversely affects

the user’s ability to properly focus

the unit.

10

Eyepiece Ring

Rotate the eyepiece ring to make sure the eyepiece is not

too tight or too loose. Range is approximately ½ turn.

Ring gets stuck, is too loose, or ad-

versely affects the user’s ability to

properly adjust the diopter.

11

Optional

Equipment

Inspect optional items for dirt, or corrosion, damage, and

missing parts. Check for proper operation.

If necessary, clean as detailed in Part 4.4.2.

Equipment is damaged or parts are

missing.

OPERATIONAL CHECKS

CAUTION:

Do not activate the Spark in daylight unless the lens cap is on, or you are operating under dark conditions.

NOTE:

Daylight checks are described below.

12

Function Switch

Install the battery. Turn the switch from OFF to ON. Look for

the green glow in eyepiece (it should appear after a slight

delay), and wait about 10 s for image to disappear.

Image is present.

13

Viewed Image

Inspect for any operational defects (refer to Part 4.3.1: Iden-

tification of Operational Defects).

Shading, edge glow, flashing, flick-

ering, and intermittent operation,

or excessive cosmetic defects are

found.

AFTER CHECKING PROCEDURES

14

Turn the unit OFF. Verify that the green glow fades from the

eyepieces.

Remove the battery.

Return the unit and all accessories to the soft carrying case.

4.2 TROUBLESHOOTING

4.2.1 OPERATOR TROUBLESHOOTING

The purpose of troubleshooting is to identify the most frequently occurring equipment malfunctions,

their probable causes, and the corrective actions required to fix them.

Table 4-2 lists common malfunctions that may occur during the operation or maintenance of the Spark.

Perform the tests, inspections, and corrective actions in the order listed in the table.

TABLE 4-1. CONTINUED