Q-tech, Qcc325 series, Reflow profile – Q-Tech QCC325 User Manual

Page 3: Embossed tape and reel information, Environmental and mechanical specifications, Reel size (diameter in mm) qty per reel (pcs)

3

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-tech.com

QCC325 SERIES

LOW PROFILE 5 x 3.2mm MINIATURE SMD CRYSTAL OSCILLATORS

1.8 to 5.0Vdc - 1MHz to 220.000MHz

QCC325 (Revision F, August 2010) (ECO# 9911)

Q-TECH

CORPORATION

Vdd

GND

0.1xVdd

0.9xVdd

VOH

VOL

Tr

Tf

TH

T

0.5xVdd

SYMMETRY = x 100%

TH

T

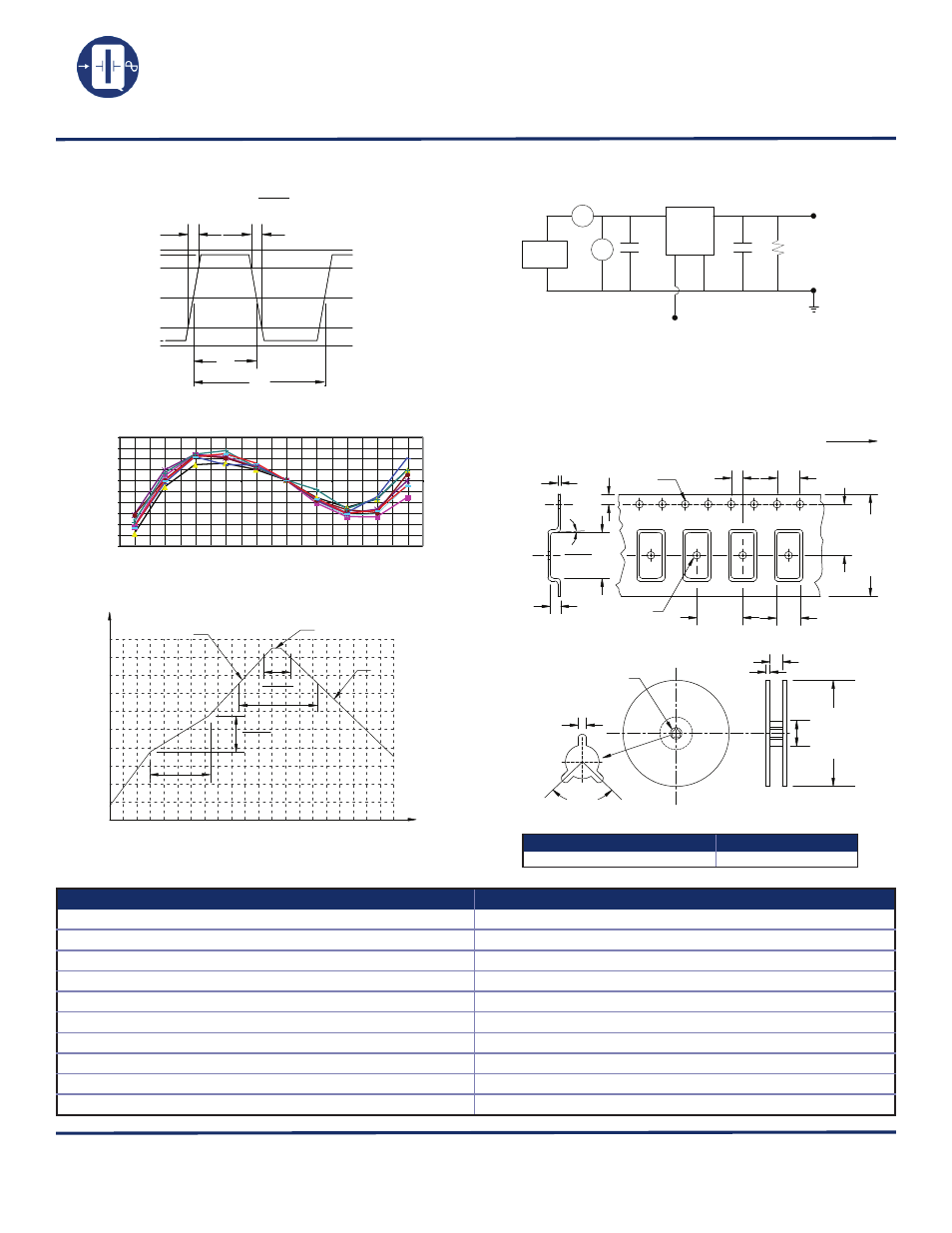

Output Waveform (Typical)

Frequency vs. Temperature Curve

Test Circuit

The Tristate function on pin 1 has a built-in pull-up resistor so it can be left

floating or tied to Vdd without deteriorating the electrical performance.

Reflow Profile

0

20

40

60

80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420

Time (s)

25

50

75

100

125

150

175

200

225

250

TEMP(*C)

0

60s min.

120s max.

60s min.

120s max.

225º min.

240º max.

60s min.

150s max.

240º

Ramp down (6ºC/s Max)

Ramp up (3ºC/s Max)

TYPICAL REFLOW PROFILE FOR Sn-Pb ASSEMBLY

Embossed Tape and Reel Information

Dimensions are in mm. Tape is compliant to EIA-481-A.

FEEDING (PULL) DIRECTION

ø13.0±0.5

2.5

1.4±0.1

5º MAX

ш1.5

2.0

1.75±0.1

0.3±.005

ш1.5

2.0±0.1

5.5±0.1

3.5±0.1

4.0±0.1

ш80±1

ш178±1

17.5

12.0±0.3

8±0.1

5.4

±0.1

120º

Reel size (Diameter in mm)

Qty per reel (pcs)

178

1,000

-

-

Output

Ground

4

3

2

0.1µF

15pF

1

Tristate Function

Power

supply

10k

mA

Vdc

+

+

+

(*)

or

0.01µF

QCC325

(*) CL includes probe and jig capacitance

Typical test circuit for CMOS logic

Environmental and Mechanical Specifications

FREQUENCY VS. TEMPERATURE QCC325L15 20MHz

-6

-5

-4

-3

-2

-1

0

1

2

3

4

-40

-25

-10

5

15

25

40

55

70

85

Temp (°C)

p

p

m

Environmental Test

Test Conditions

Temperature cycling

MIL-STD-883, Method 1010, Cond. B

Constant acceleration

MIL-STD-883, Method 2001, Cond. A, Y1

Seal: Fine and Gross Leak

MIL-STD-883, Method 1014, Cond. A and C

Vibration sinusoidal

MIL-STD-202, Method 204, Cond. D

Shock, non operating

MIL-STD-202, Method 213, Cond. I

Resistance to solder heat

MIL-STD-202, Method 210, Cond. B

Resistance to solvents

MIL-STD-202, Method 215

Solderability

MIL-STD-202, Method 208

ESD Classification

MIL-STD-883, Method 3015, Class 1 HBM 0 to 1,999V

Moisture Sensitivity Level

J-STD-020, MSL=1