Pro Series 97200 51 Receiver User Manual

Installation instructions, Ford edge lincoln mkx, Part numbers

Installation Instructions

Ford Edge

Lincoln MKX

Part Numbers:

51200

97200

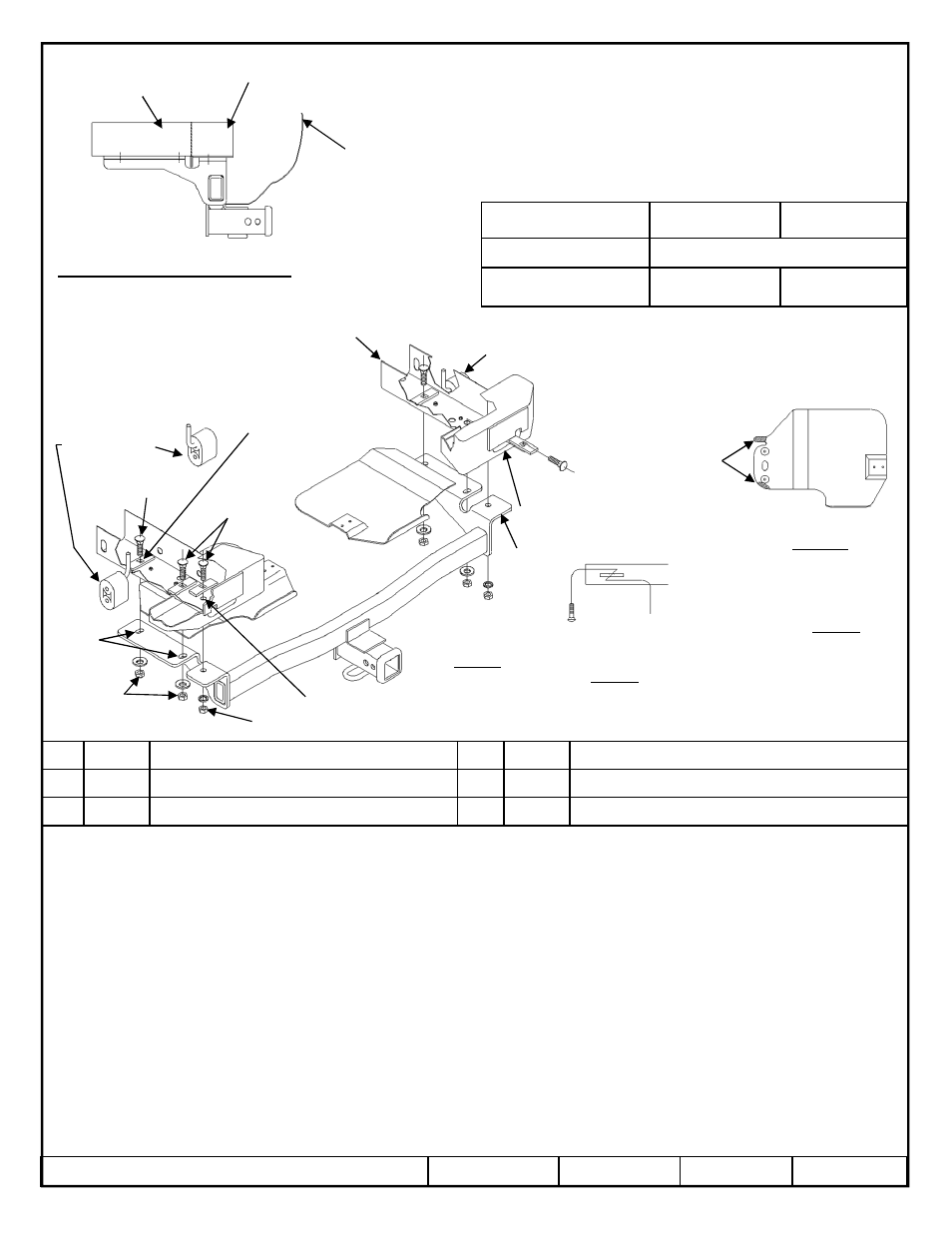

Hitch Shown In Proper Position

Equipment Required: ½” Pull wire (Provided), Tin Snips

Wrenches: 3/4”, 5.5mm, 8mm

Drill Bits: ½”

Ford Edge

Fascia

Figure 1

1.

Lower exhaust system at the rubber isolator (3 places) leaving the rubber isolator in place on the vehicle. Spraying a lubricant on the metal hanger rod

and the rubber isolator helps removal. Be careful not to allow muffler to fall under its own weight.

2.

Disconnect the fascia center support (1 screw) and carefully push it toward the impact bar and out of the way. Reinstall screw.

3.

Remove both heat shields (3 screws) and a plastic insert each side. Return (4) screws to owner.

4.

Trim both heat shields as shown. Figure 2.

5.

Using the kink wire (see Figure 3) method for feeding fasteners attach carriage bolt and block to the pull wire. Feed forward fasteners into place on both

rails using the access hole at the end of the frame rail. On the outside end of both rails there is a wide notch to make this process easier. Feed middle

fasteners into location using the same method. Note: Make sure spacers are sitting flat on the rails and not on existing weld nuts.

6.

Replace trimmed heat shields using the remaining inboard fasteners and plastic insert.

7. Raise hitch into position over the exhaust. Sandwiching the heat shield between the hitch and the rail.

8.

Loosely attach fasteners as shown, center hitch on vehicle and tighten fastener to 75 Lb.-Ft. (102 N*M).

9.

Using rearmost holes in hitch side brackets as a template, drill ½” holes in rear cross member.

10.

Using the kink wire (see Figure 3) method for feeding fasteners attach carriage bolt and block to the pull wire. Feed rearward fasteners into place on both

rails using the access hole at the end of the frame rail. Install remaining fasteners as shown above. Tighten ½-13 GR5 fasteners to 75 lb.-ft. (102 N*M) .

11. Raise exhaust system (3) places back into position.

© 2010, 2013 Cequent Performance Products – Printed in Mexico

Sheet 1 of 3

51200N

5-29-13

Rev. C

1

1

1

1

Qty. (6)

Carriage Bolt ½-13 X 1.500 GR5

4

4

4

4

Qty. (4)

Spacer ¼ X 1 X 3

2

2

2

2

Qty. (4)

Conical Washer

5

5

5

5

Qty. (2)

Lock Washer ½”

3

3

3

3

Qty. (6)

Hex Nut ½-13

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to prevent

entry of water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working beneath a

vehicle and wear eye protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5 and

SAE J684.

Fastener Kit: 51200F

Do Not Exceed Lower of Towing Vehicle

Manufacturer’s Rating or

Wiring Access Location: SUV1 & SUV2

Form: F205 Rev A 5-6-05

1

4

Frame Rail

Figure 2

Figure 3

Trim both heat shields.

As shown

Leave enough to

sandwich between frame

and hitch

Kink Pull wire to keep spacer

independent of bolt

Frame rail

Access hole at end

of rails

Rubber isolator

Rubber isolator

Forward

hole

Hitch type

Max Gross

Trailer WT (LB)

Max Tongue

WT (LB)

Weight Distributing

Not For Use With Spring Bars

Weight Carrying

Ball Mount

4000 (1816 Kg)

400 (182 Kg)

Fasteners typical both sides.

Drilled hole

2

3

5

3

1

4

Trim here

(

Excluding Sport Model)

Attaches to rear cross member

Attaches

to frame

Cross member