Pro Series 51202 51 Receiver User Manual

Installation instructions

Rubber

isolator

Installation Instructions

Ford Explorer

For vehicles with OEM Tow Hook:

Tow hook must be permanently

removed for hitch installation.

Part Numbers:

51202

Hitch Shown In Proper Position

Equipment Required: Pullwire ( provided),

Lubricant or Soapy water

Wrenches: 18mm, 19mm, 3/4”, 11/16”

and 6” Ratchet extension,

Existing weldnuts

Both sides

Fastener Kit: 51202F

Do Not Exceed Lower of Towing Vehicle

Manufacturer’s Rating or

Hitch type

Max Gross

Trailer WT (LB)

Max Tongue

WT (LB)

Weight Distributing

5000 (2270 Kg)

500 (227 Kg)

Weight Carrying

Ball Mount

4000 (1816 Kg)

400 (182 Kg)

Wiring Access Location: SUV3 & SUV4

1

1

1

1

2

2

2

2

1

1

1

1

3

3

3

3

4

4

4

4

6

6

6

6

6

6

6

6

6

6

6

6

7

7

7

78

8

8

8

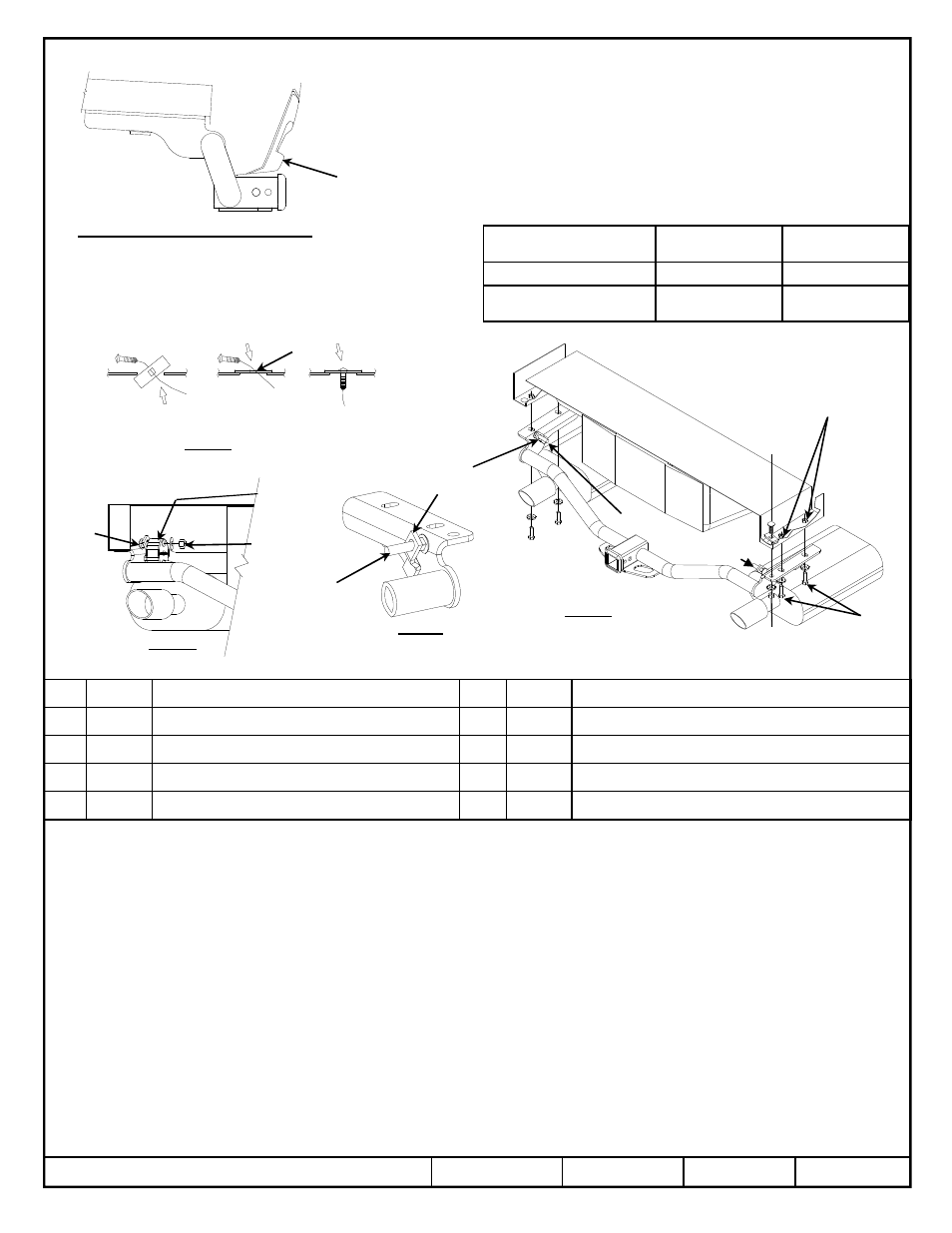

Figure 2

Reverse pull wire procedure

A. Insert bolt and

block into frame

B. Align block on

access hole

C. Pull bolt thru

block

Figure 1

9

9

9

9

Fascia

Hitch exhaust

hangers (2)

6

6

6

6

For vehicles with OEM Tow Hook: Tow hook must be permanently removed for hitch installation.

1.Lower exhaust system at the rubber isolator (3 places). Note: Spraying a lubricant or soapy water on the metal hanger rod and the rubber isolator helps

removal. Remove rubber isolator from mufflers only (2) to be re-install step 3. Be careful not to allow muffler to fall under its own weight.

2.Remove and return exhaust hanger, and/or exhaust hanger with factory tow hook, and fasteners to vehicle owner.

3.Install carriage bolts (item 6) into exhaust hangers on hitch. Install rubber isolators removed in step 1, onto 7/16 carriage bolts on hitch. Install flat

washer, and 7/16-14 hex lock nut. See Figure 3.

4.Feed ½-13 carriage bolt and spacer into passenger side frame rail as shown using reverse pullwire procedure. Leave pullwire attached. See Figure 2.

5.Feed pull wire though hole in bracket on passenger side. Raise hitch into position, over exhaust and align with existing weldnuts in frame rail and ½-13

carriage bolt installed in Step 4. Install M12 hex bolts and conical washer as shown.

6.Remove pullwire and install conical washer and hex nut on carriage bolt.

7.Tighten all fasteners to the required torque specificaion.

8.Raise exhaust back into position (3 places). Note: Spraying a lubricant or soapy water on the metal hanger rod and the rubber isolator helps.

Tighten all M12 CL.8.8 fasteners with torque wrench to 68 Lb.-Ft (92 N*M)

Tighten all ½-13 GR5 fasteners with torque wrench to75 Lb.-Ft. (102 N*M)

©

2011 Cequent Performance Products

Sheet 1 of 3

51202N

7-28-11

Rev. A

1

1

1

1

Qty. (4)

Hex bolt M12 x 1.75 x 40mm CL8.8

6

6

6

6

Qty. (2)

Bolt carriage 7/16-14 x 2.500 GR5

2

2

2

2

Qty. (5)

Conical washer 1/2”

7

7

7

7

Qty. (2)

Flat washer 7/16

3

3

3

3

Qty. (1)

Bolt Carriage ½-13 x 1.50 GR5

8

8

8

8

Qty. (2)

Hex lock nut 7/16-14

4

4

4

4

Qty. (1)

Spacer ¼” x 1.00 x 2.00

9

9

9

9

Qty. (1)

Pullwire

5

5

5

5

Qty. (1)

Hex nut 1/2-13

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to prevent entry of

water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working beneath a vehicle and wear eye

protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5 and SAE J684.

Form: F205 Rev A 5-6-05

1

1

1

1

2

2

2

2

2

2

2

2

5

5

5

5

STEP 3

Must be install before hitch is

raised into position

Figure 1

Figure 3

Both sides