OSRAM VALUE Flex Advanced User Manual

Page 2

2

3

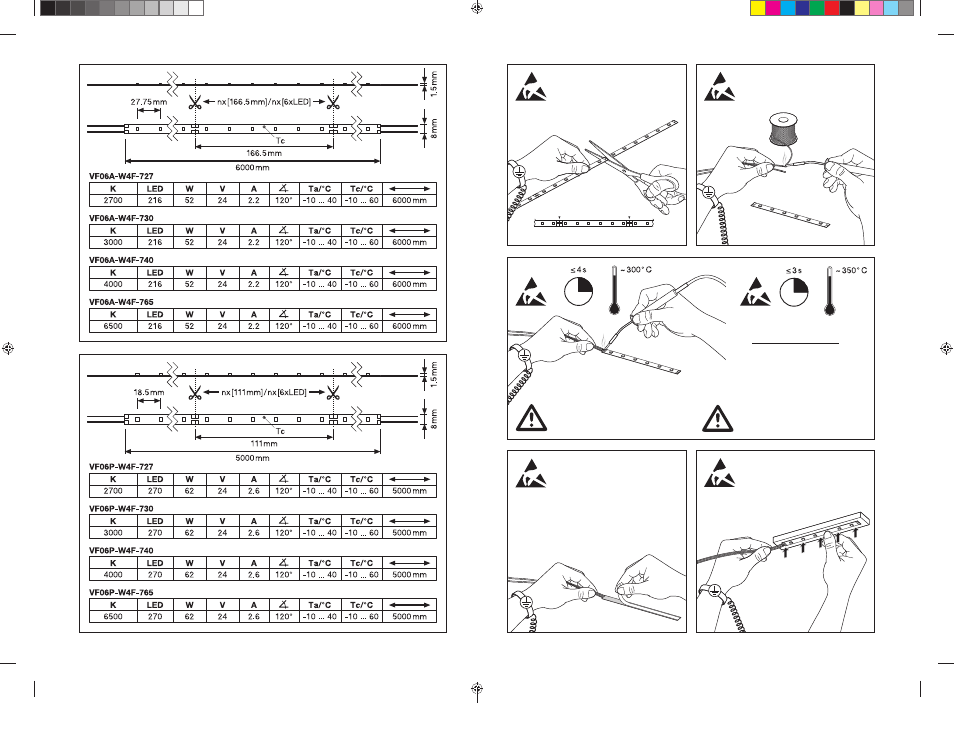

VF06A

VF06P

1

2

3b

3a

5

4

Care must be taken to provide a clean and

even mounting surface, which assures,

that the allowed operating temperatures

(~300°C/≤4s) are not exceeded.

Soldering of wires with the module mounted

on a thermally conducted surface:

• Pretin solderpads and wires

and solder for max 3s at 350°C.

• Allow solderpoints to completely

cool down before the next soldering.

• Prevent shear- or peel forces.

When mounting on metallic or otherwise

conductive surfaces, there needs to be an

electrical isolation at soldering points be-

tween module and the mounting surface.

The mounting of the module is facilitated

by means of the double-sided adhesive

on the back-surface of the module. Care

must be taken to provide a clean and dry

mounting surface, free of oils or silicone coatings as

well as dirt particle. The mounting substrate must have

suffi cient structural integrity. Take care to completely

remove the protective backing.

焊接需在干净平坦的操作面上进行,并且确保

不会超过所允许的操作温度(~300°C/≤4s)。

通过模组背面的双面胶将有助于产品安装。注意安装面需清

洁、干燥、无油脂或树脂涂层以及不净颗粒物。安装基底必

须要有足够的结构完整性。请小心完整地移除保护胶条。

焊接模块连接线时需在导热较好的表面上进行

• 连线和焊盘上需做预上锡处理,焊接过程中在

350°C焊接温度下最多停留3秒钟。

• 需待焊点完全冷却后再进行后续焊接

• 注意剪切或剥离力度,以免造成模块损伤

当安装在金属或其他导电表面时,在焊点及安

装面之间需要做电子绝缘处理。

#11709

black

148 x 210 mm

#11709

black

148 x 210 mm

G10447913_LINEARlight_Flex_Value_VF06A_VF06P_03.indd 2-3

G10447913_LINEARlight_Flex_Value_VF06A_VF06P_03.indd 2-3

11.03.13 11:06

11.03.13 11:06