Axial lead & cartridge fuses, Product characteristics, Soldering parameters - wave soldering – Littelfuse 235 Series User Manual

Page 3

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Axial Lead & Cartridge Fuses

5×20 mm > Fast-Acting > 235 Series

Materials

Body: Glass

Cap: Nickel–plated brass

Leads: Tin–plated Copper

Terminal Strength

MIL-STD-202G, Method 211A.

Test Condition A

Solderability

Reference IEC 60127 Second Edition

2003-01 Annex A

Product Marking

Cap 1: Brand logo, current and voltage

rating

Cap 2: Series and agency approval

markings

Packaging

Available in Bulk (M=1000 pcs/pkg) or on

Tape/Reel (MRET1=1000 pcs/reel)

Product Characteristics

Operating Temperature

–55ºC to +125ºC

Thermal Shock

MIL-STD-202G, Method 107G, Test

Condition B: (5 cycles –65

O

C +

125

O

C)

Vibration

MIL-STD-202G, Method 201A

Humidity

MIL-STD-202G, Method 103B, Test

Condition A high RH (95%) and

elevated temperature (40

O

C) for 240

hours

Salt Spray

MIL-STD-202G, Method 101D, Test

Condition B

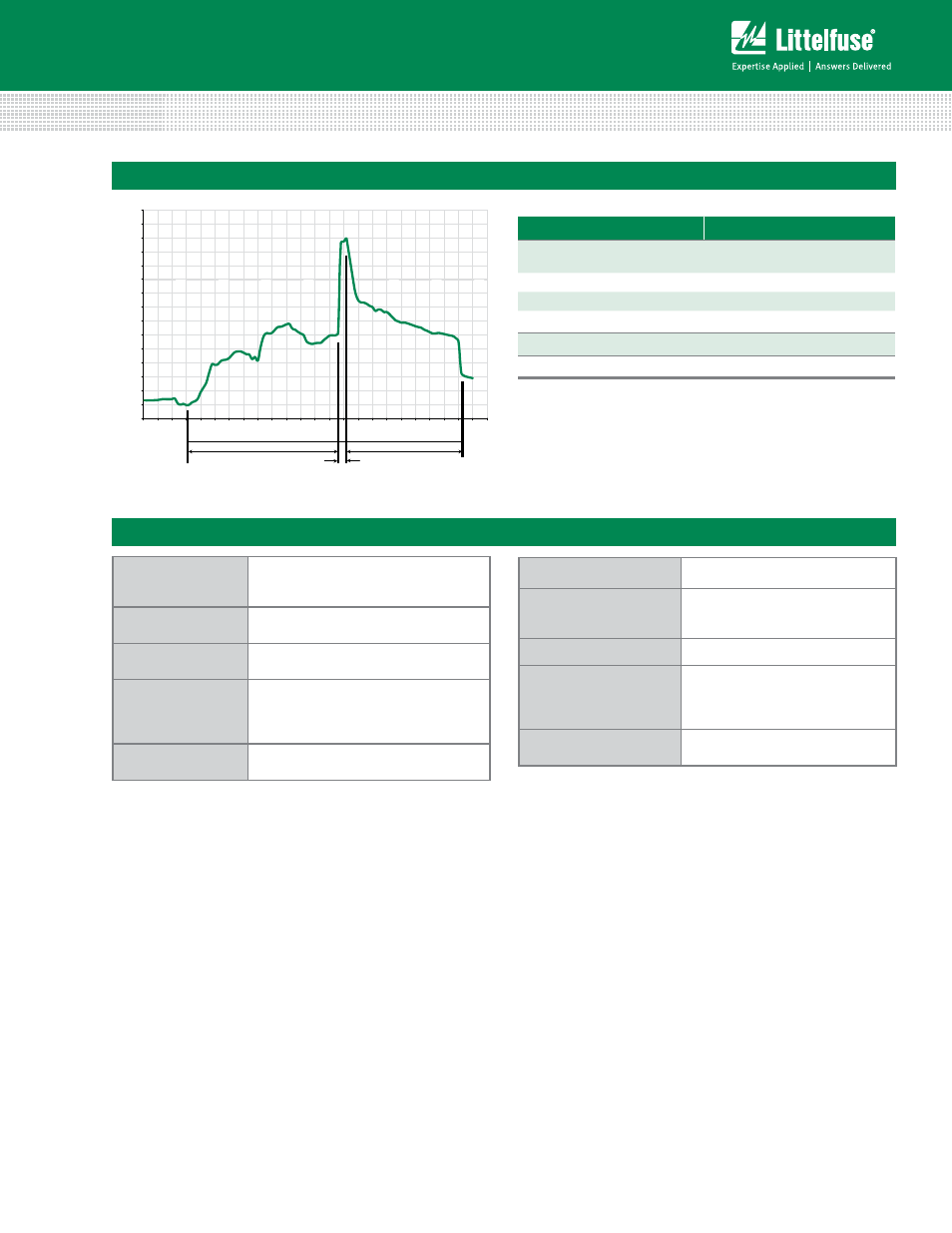

Soldering Parameters - Wave Soldering

Dwell Time

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

Time (Seconds)

Temperature (°C) - Measured on bottom side of board

Cooling Time

Preheat Time

Wave parameter

lead-Free Recommendation

preheat:

(Depends on Flux Activation Temperature)

(Typical Industry Recommendation)

Temperature Minimum:

100

°

C

Temperature Maximum:

150

°

C

Preheat Time:

60-180 seconds

Solder pot Temperature:

260

°

C Maximum

Solder Dwell Time:

2-5 seconds

Recommended Hand-Solder Parameters:

Solder Iron Temperature: 350° C +/- 5°C

Heating Time: 5 seconds max.

Note: These devices are not recommended for IR or

Convection Reflow process.

Recommended Process Parameters: