Varistor products, Refl ow solder profi le wave solder profi le – Littelfuse MLN SurgeArray Suppressor User Manual

Page 4

© 2013 Littelfuse, Inc.

66

Revised: October 9, 2013

Varistor Products

MLN SurgeArray™ Suppressor

Surface Mount Multilayer Varistors (MLVs) > MLN Series

Specifi cations are subject to change without notice.

Please refer to www.littelfuse.com/series/MLN.html for current information.

Lead (Pb) Soldering Recommendations

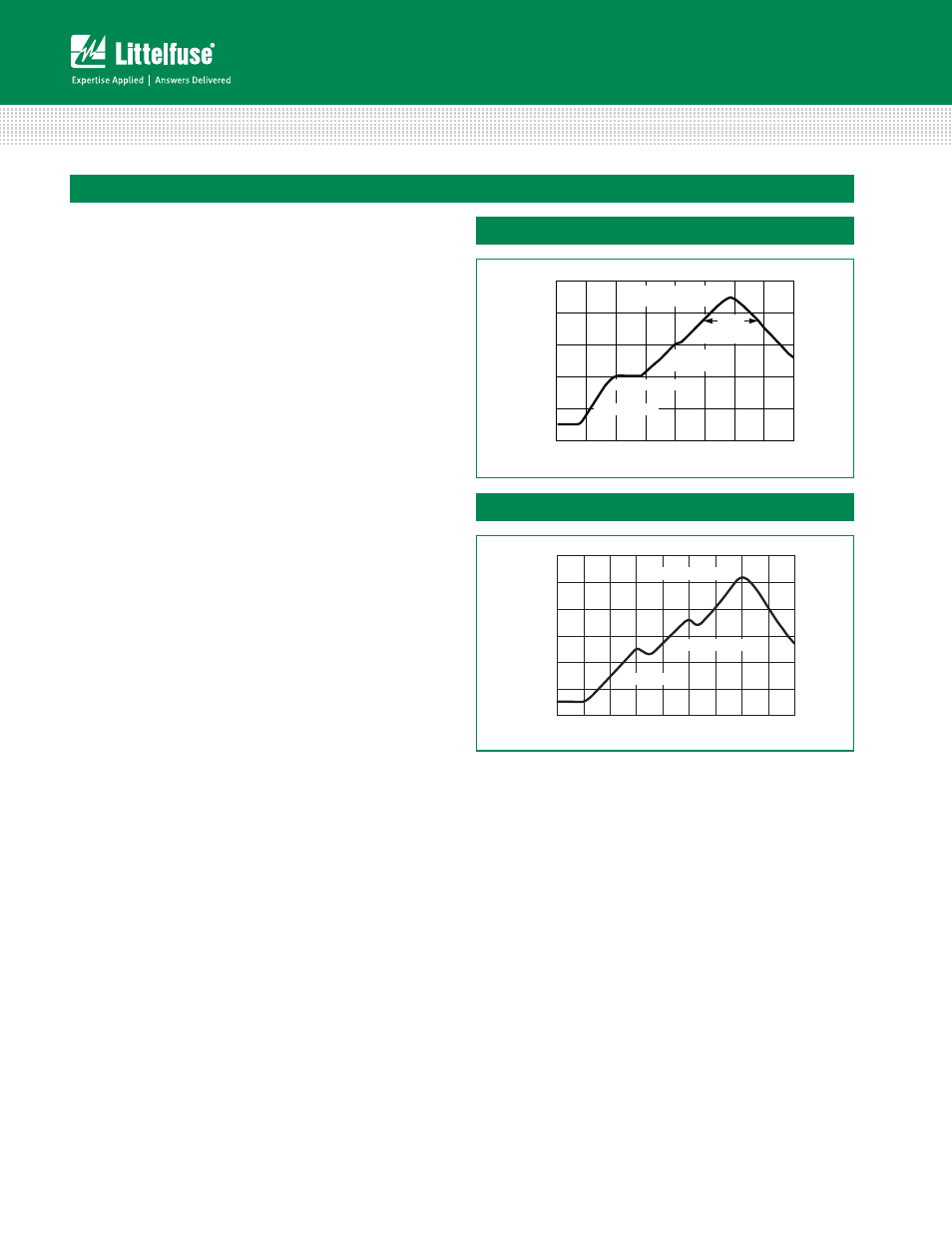

The principal techniques used for the soldering of

components in surface mount technology are IR Re-fl ow

and Wave soldering. Typical profi les are shown on the right.

The recommended solder for the MLN suppressor is

a 62/36/2 (Sn/Pb/Ag), 60/40 (Sn/Pb) or 63/37 (Sn/Pb).

Littelfuse also recommends an RMA solder fl ux.

Wave soldering is the most strenuous of the processes.

To avoid the possibility of generating stresses due to

thermal shock, a preheat stage in the soldering process

is recommended, and the peak temperature of the solder

process should be rigidly controlled.

When using a refl ow process, care should be taken to

ensure that the MLN chip is not subjected to a thermal

gradient steeper than 4 degrees per second; the ideal

gradient being 2 degrees per second. During the soldering

process, preheating to within 100 degrees of the solder's

peak temperature is essential to minimize thermal shock.

Once the soldering process has been completed, it is

still necessary to ensure that any further thermal shocks

are avoided. One possible cause of thermal shock is hot

printed circuit boards being removed from the solder

process and subjected to cleaning solvents at room

temperature. The boards must be allowed to cool gradually

to less than 50ºC before cleaning.

PREHEAT ZONE

PREHEAT DWELL

RAMP RATE

<2°C/s

MAXIMUM TEMPERATURE

230°C

TEMPER

A

TURE °C

TIME (MINUTES)

250

200

150

100

50

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

40-80

SECONDS

ABOVE 183°C

TIME (MINUTES)

300

250

200

150

100

50

0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

MAXIMUM WAVE 260°C

SECOND PREHEAT

FIRST PREHEAT

TEMPER

A

TURE °C

Refl ow Solder Profi le

Wave Solder Profi le

Figure 10

Figure 11