Clamping voltage vs. ipp, Pulse waveform, Soldering parameters – Littelfuse SP4021 Series User Manual

Page 3: Product characteristics, Tvs diode arrays, Lightning surge protection- sp4021 series, Diodes), Sp4021, Clamping voltage vs. i, Soldering parameters product characteristics

3

©2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to

www.littelfuse.com

for current information.

TVS Diode Arrays

(SPA

®

Diodes)

Revision: July 12, 2013

Lightning Surge Protection- SP4021 Series

SP4021

SP4021 Series

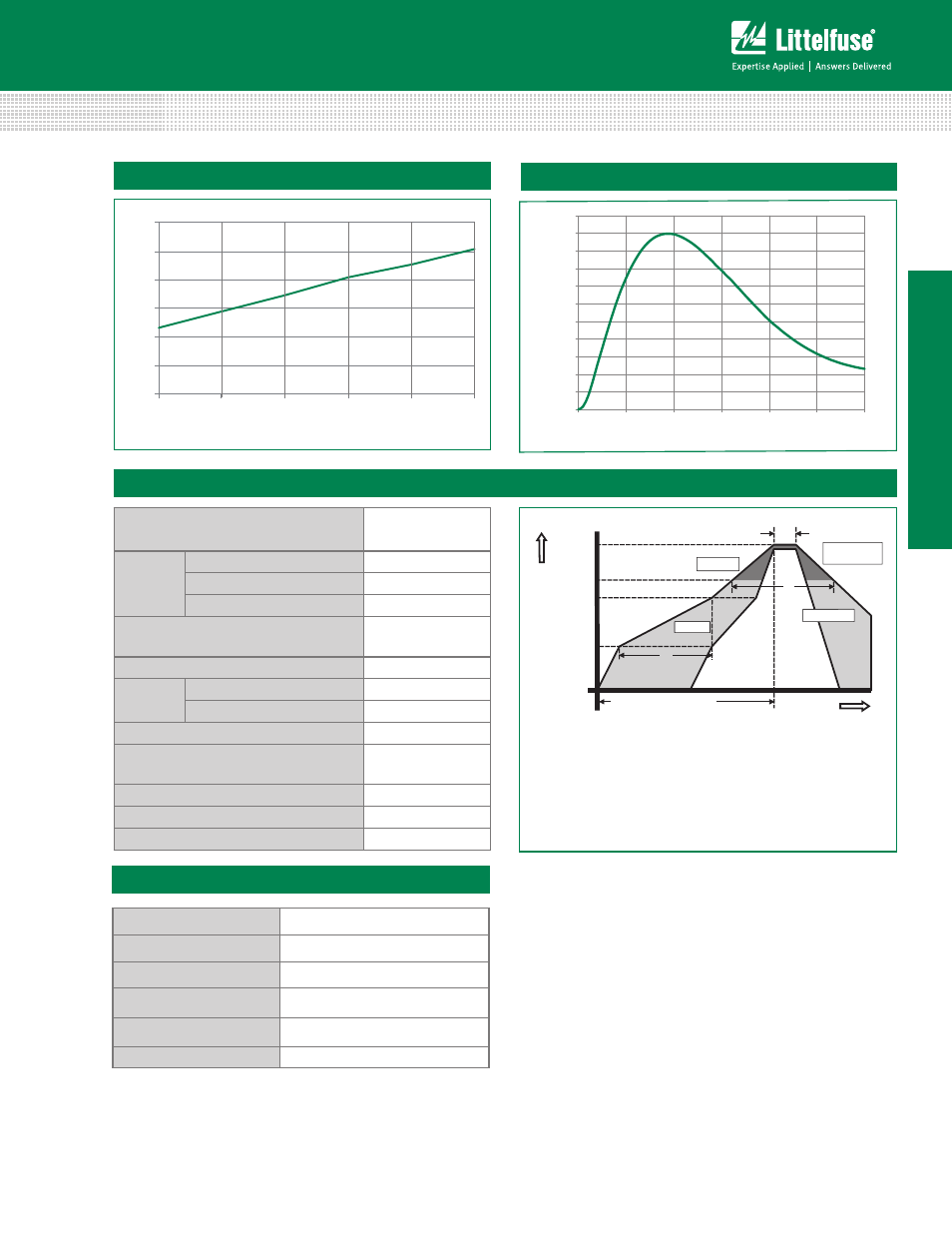

Clamping Voltage vs. I

PP

25.0

10.0

20.0

5.0

15.0

Cl

am

p

Vo

lt

age

(V

C

)

0.0

4.0

8.0

12.0

16.0

20.0

24.0

1.0

Peak Pulse Current-I

PP

(A)

Time

Temperature

T

P

T

L

T

S(max)

T

S(min)

25

t

P

t

L

t

S

time to peak temperature

Preheat

Preheat

Ramp-up

Ramp-up

Ramp-down

Ramp-do

Critical Zone

T

L

to T

P

Critical Zone

T

L

to T

P

Reflow Condition

Pb – Free assembly

Pre Heat

- Temperature Min (T

s(min)

)

150°C

- Temperature Max (T

s(max)

)

200°C

- Time (min to max) (t

s

)

60 – 180 secs

Average ramp up rate (Liquidus) Temp

(T

L

) to peak

3°C/second max

T

S(max)

to T

L

- Ramp-up Rate

3°C/second max

Reflow

- Temperature (T

L

) (Liquidus)

217°C

- Temperature (t

L

)

60 – 150 seconds

Peak Temperature (T

P

)

260

+0/-5

°C

Time within 5°C of actual peak

Temperature (t

p

)

20 – 40 seconds

Ramp-down Rate

6°C/second max

Time 25°C to peak Temperature (T

P

)

8 minutes Max.

Do not exceed

260°C

Soldering Parameters

Product Characteristics

Lead Plating

Matte Tin

Lead Material

Copper Alloy

Lead Coplanarity

0.0004 inches (0.102mm)

Substitute Material

Silicon

Body Material

Molded Epoxy

Flammability

UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte finish VDI 11-13.

Pulse Waveform

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Time (μs)

Percent of

I

PP