Axial lead & cartridge fuses, Ab c c – Littelfuse 216SP Series User Manual

Page 2

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Axial Lead & Cartridge Fuses

5×20 mm > Fast-Acting > 216SP Series

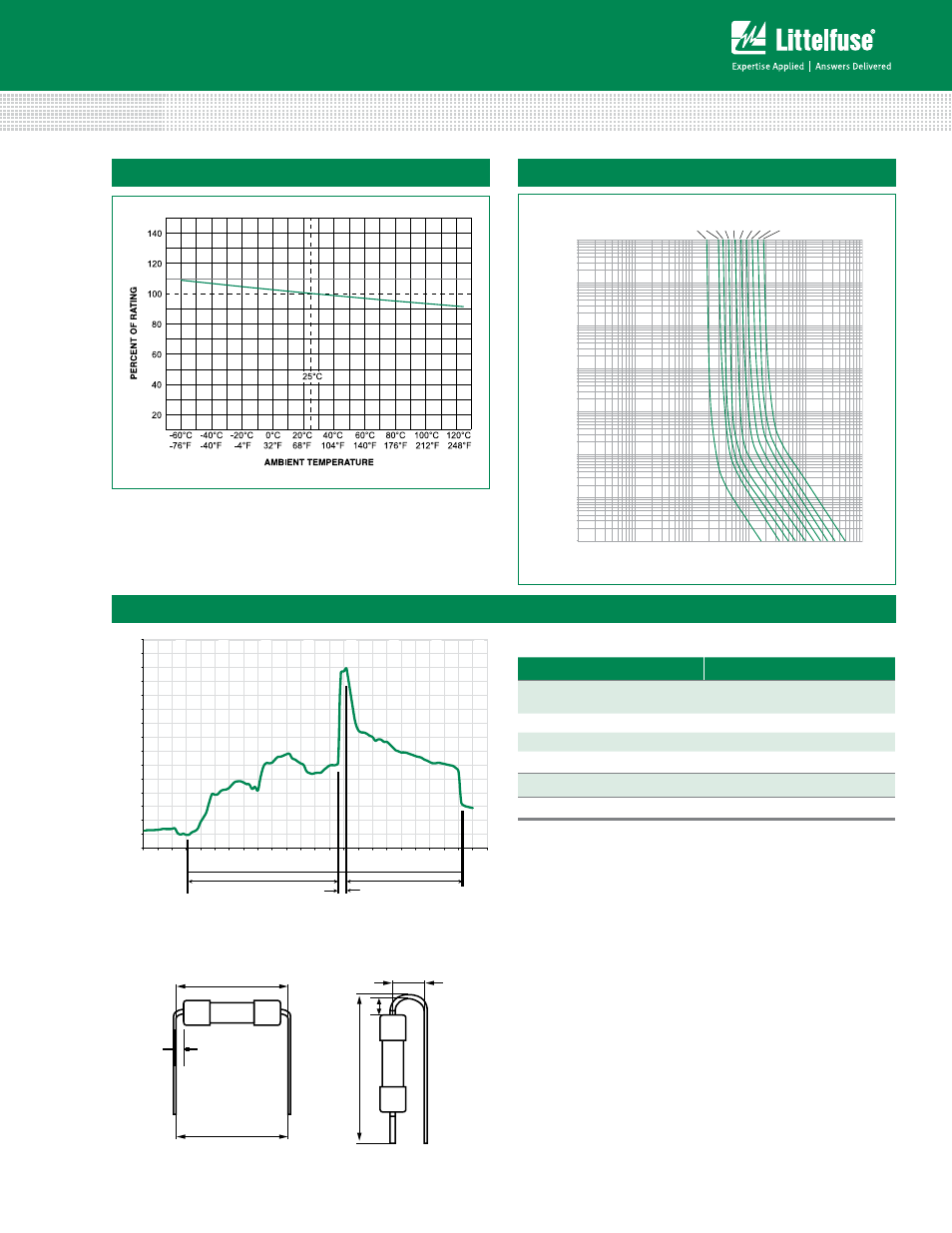

Average Time Current Curves

Soldering Parameters - Wave Soldering

Dwell Time

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

Time (Seconds)

Temperature (°C) - Measured on bottom side of board

Cooling Time

Preheat Time

Wave parameter

lead-Free Recommendation

preheat:

(Depends on Flux Activation Temperature)

(Typical Industry Recommendation)

Temperature Minimum:

100

°

C

Temperature Maximum:

150

°

C

Preheat Time:

60-180 seconds

Solder pot Temperature:

280

°

C Maximum

Solder Dwell Time:

2-5 seconds

Recommended Hand-Solder Parameters:

Solder Iron Temperature: 350° C +/- 5°C

Heating Time: 5 seconds max.

Note: These devices are not recommended for IR or

Convection Reflow process.

Recommended Process Parameters:

0.001

0.01

0.1

1

10

100

1000

10000

0.01

0.1

1

10

100

Time (seconds)

Amps

1.6A

1A

2A 2.5A 3.15A 4A 5A 6.3A 8A 10A

Temperature Rerating Curve

For the pigtailed fuse, please follow the recommendations

below for axial lead forming and mounting into PCB:

Lead forming:

The distance C between cap flat surface and axial lead shall

be greater than 1.0 mm.

PCB mounting:

According to the standard of IPC-A-610, the distance

between PCB and fuse cap is recommended to be a

minimum of 1.5 mm.

A

B

C

C

A

B

Different values of A and B available, please contact the Littelfuse sales representative in your region: