Surface mount fuses, Ceramic fuse > 440 series, Average time current curves – Littelfuse 440 Series User Manual

Page 2: Soldering parameters temperature derating curve

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Surface Mount Fuses

Ceramic Fuse > 440 Series

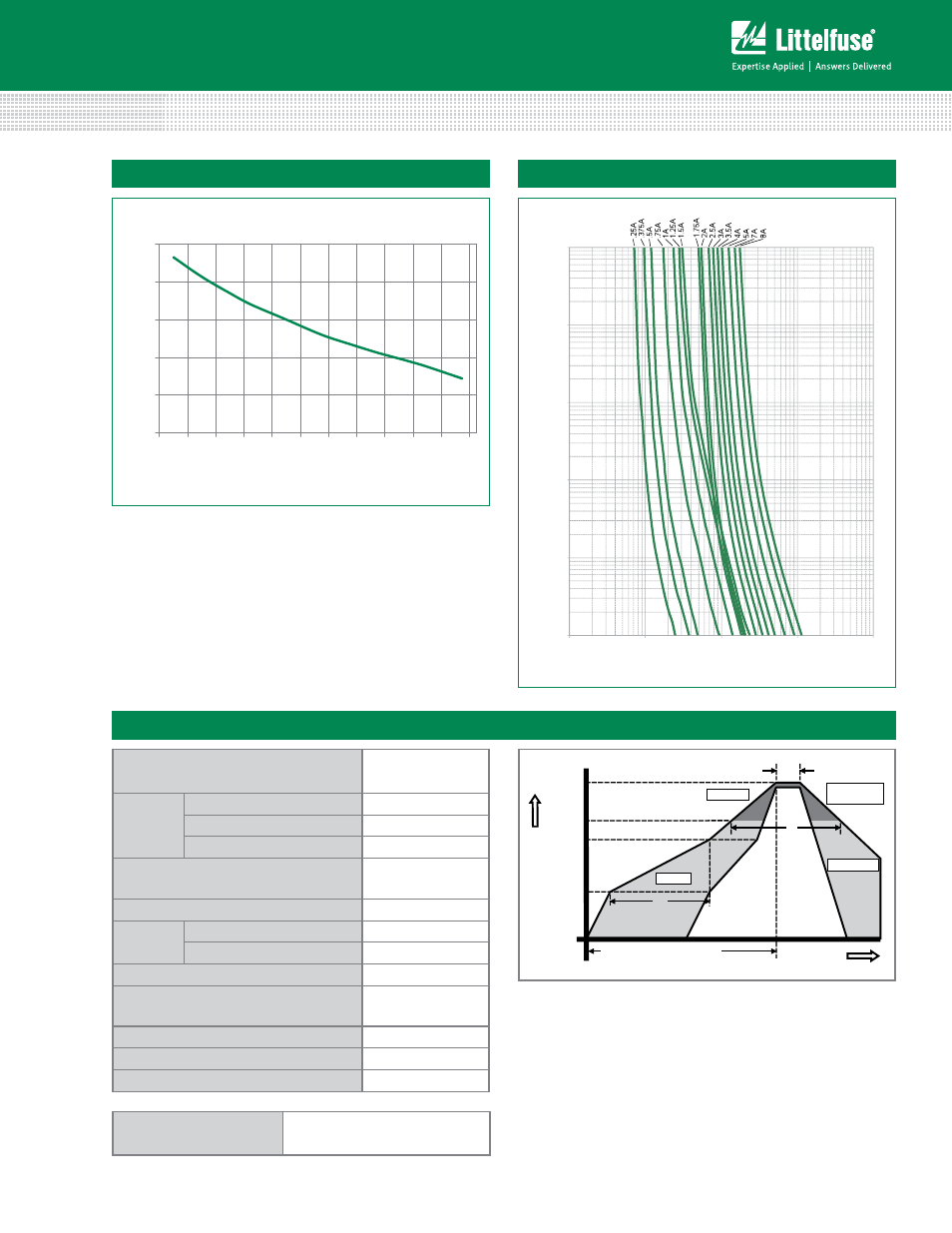

Average Time Current Curves

0.001

0.1

1.0

10.0

100.0

1000.

0.01

0.1

1

10

100

TIME IN SECONDS

CURRENT IN AMPERES

Reflow Condition

Pb-free assembly

pre Heat

- Temperature min (T

s(min)

)

150°C

- Temperature max (T

s(max)

)

200°C

- Time (min to max) (t

s

)

60 – 180 seconds

Average Ramp-up Rate (liquidus Temp

(T

l

) to peak)

3°C/second max.

T

S(max)

to T

l

- Ramp-up Rate

5°C/second max.

Reflow

- Temperature (T

l

) (liquidus)

217°C

- Temperature (t

l

)

60 – 150 seconds

peak Temperature (T

p

)

260

+0/-5

°C

Time within 5°C of actual peak

Temperature (t

p

)

10 – 30 seconds

Ramp-down Rate

6°C/second max.

Time 25°C to peak Temperature (T

p

)

8 minutes max.

Do not exceed

260°C

Soldering Parameters

Temperature Derating Curve

40

60

80

100

120

140

-65 -45 -25 -5 15 35 55 75 95 115 135 155

TEMPERATURE (°C)

PE

RC

EN

T

OF

RA

TI

NG

Time

Te

mperatur

e

T

P

T

L

T

S(max)

T

S(min)

25

t

P

t

L

t

S

time to peak temperature

(t 25ºC to peak)

Ramp-down

Ramp-up

Preheat

Critical Zone

T

L

to T

P

Example:

For continuous operation at 75 degrees celsius, the fuse should be derated as follows:

I = (0.80)(0.85)I

RAT

= (0.68)I

RAT

Note:

1. Derating depicted in this curve is in addition to the standard derating of 20% for

continuous operation.

Wave Soldering

260°C, 10 seconds max.