Pled open led protectors, Pled 6 m, Pled6m series – Littelfuse PLED6M Series User Manual

Page 4

4

PLED Open LED Protectors

Revision: June 13, 2012

©2012 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to

www.littelfuse.com

for current information.

PLED6M Series

PLED6M Series

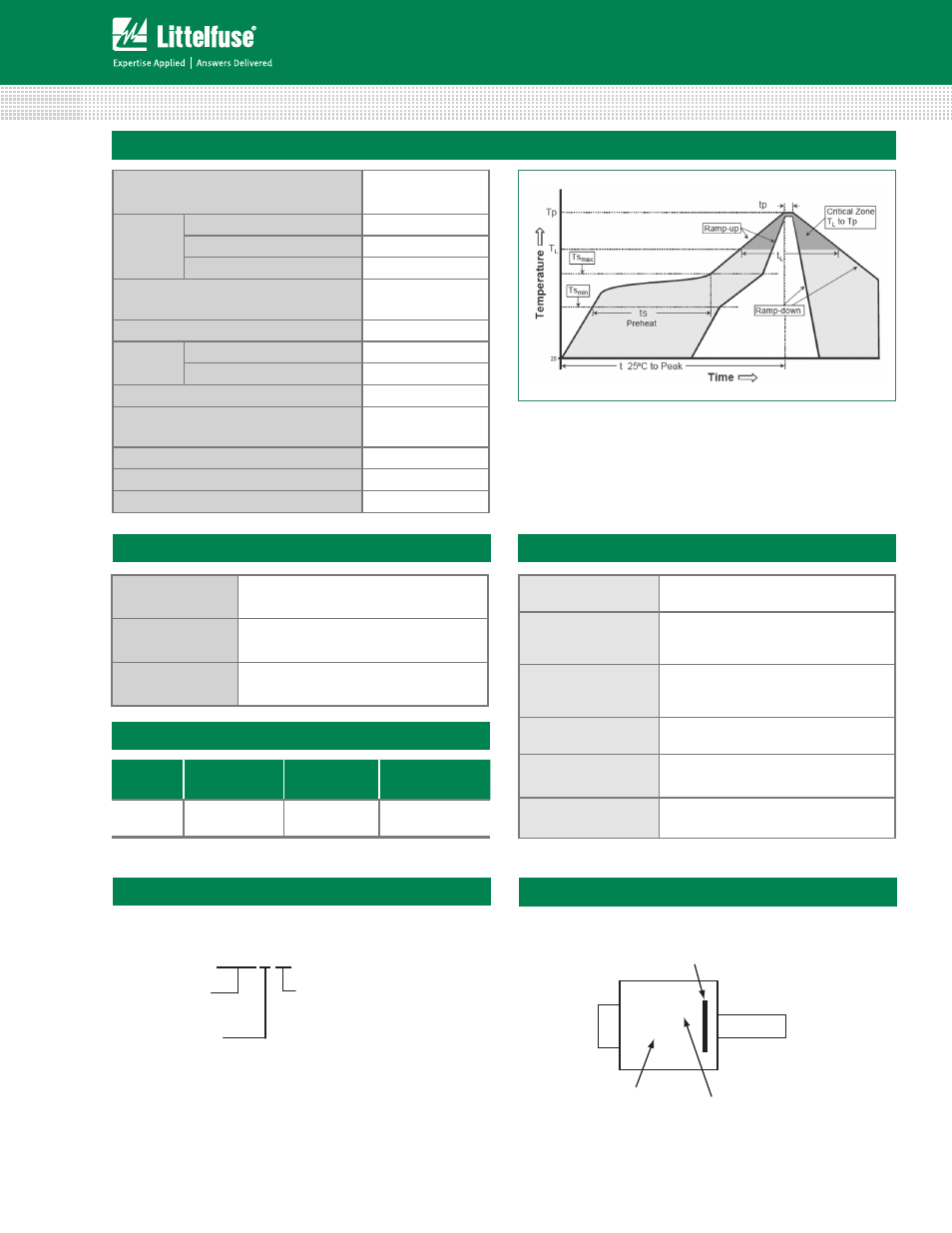

Part Marking System

P6M

XXX

Lot Number

Cathode

Anode

Product Identifier

Cathode Bar

Part Numbering System

Packaging

Package

Code

Description

Packaging

Quantity

Industry

Standard

M

POWERMITE

3000

EIA-481-1

Tape and Reel

PLED 6 M

Device Type

PLED: LED Protector

Typical V

BR

Package Type:

M: POWERMITE

Soldering Parameters

Reflow Condition

Pb – Free assembly

Pre Heat

- Temperature Min (T

s(min)

)

150°C

- Temperature Max (T

s(max)

)

200°C

- Time (min to max) (t

s

)

60 – 180 secs

Average ramp up rate (Liquidus Temp

(T

L

) to peak

3°C/second max

T

S(max)

to T

L

- Ramp-up Rate

3°C/second max

Reflow

- Temperature (T

L

) (Liquidus)

217°C

- Temperature (t

L

)

60 – 150 seconds

Peak Temperature (T

P

)

260

+0/-5

°C

Time within 5°C of actual peak

Temperature (t

p

)

30 seconds

Ramp-down Rate

6°C/second max

Time 25°C to peak Temperature (T

P

)

8 minutes max

Do not exceed

260°C

Physical Specifications

Environmental Specifications

High Temperature

Voltage Blocking

MIL-STD-750: Method 1040, Condition A

80% min V

BR

DC, 150°C, 504 hours

Temperature Cycling

MIL-STD-750: Method 1051

-65°C to 150°C, 15-minute dwell,

100 cycles

Biased Temperature &

Humidity

EIA/JEDEC: JESD22-A101

80% min V

BR

, 85°C, 85%RH,

1008 hours

Resistance to

Solder Heat

MIL-STD-750: Method 2031

260°C, 10 seconds

Moisture Sensitivity

Level

JEDEC-J-STC-020D, Level 1

Burn-In Test

T

j

= 150°C, IT = 0.350 Adc, 1008 hours

Terminal Material

Copper Alloy

Terminal Finish

100% Matte Tin Plated

Body Material

UL recognized epoxy meeting flammability

classification 94V-0