Sidactor, Protection thyristors, Broadband optimized – Littelfuse SDP Biased Series SOT23-6 User Manual

Page 4: Protection

SIDACtor

®

Protection Thyristors

4

Revised: 11/04/13

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Broadband Optimized

™

Protection

SDP Biased Series SOT23-6

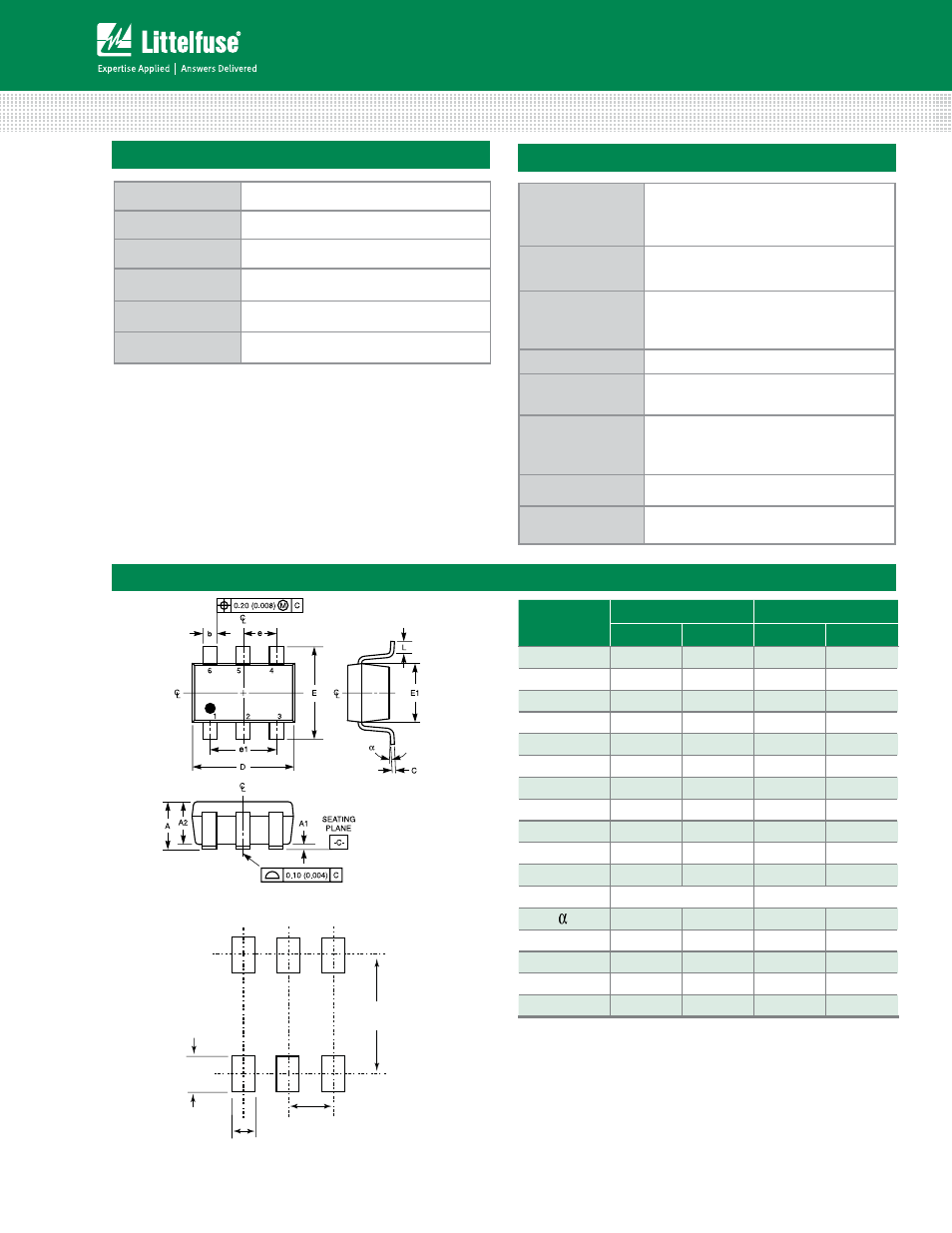

Dimensions

Inches

Millimeters

Min

Max

Min

Max

A

-

0.057

-

1.450

A1

-

0.006

-

0.150

A2

-

0.051

-

1.300

b

0.014

0.020

0.350

0.508

C

0.004

0.008

0.090

0.200

D

0.110

0.118

2.800

3.000

E

0.102

0.118

2.600

3.000

E1

0.057

0.069

1.450

1.750

e

-

0.037

-

0.950

e1

-

0.075

-

1.900

L (note 4.5)

0.004

0.023

0.100

0.600

N (note 6)

6

6

0°C

10°C

0°C

10°C

M

-

0.102

-

2.590

O

-

0.027

-

0.690

P

-

0.039

-

0.990

R

-

0.038

-

0.950

O

P

R

M

Recommended Solder Pad Layout

Notes:

1. Dimensioning and tolearances per ANSI 14.5M-1982.

2. Package conforms to EIAJ SC-74 (1992)

3. Dimensions D and E1 are exclusive of mold flash, protrusions, or gate burrs.

4. Foot lenth L measured at reference to seatng plane.

5. “L” is the length of flat foot surface for soldering to substrate.

6. “N” is the number of terminal positions.

7. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily

exact.

Dimensions - SOT23-6

Environmental Specifications

Temp Cycling

Mil-STD-883F, Method 1010.8 Condition

C, -65°C to +150°C

168 Hrs, 85°C /60%RH+3IR-Reflow,

260°C +5V, -0°C

Bias Humidity

JESD 22-A101-B 85°C , 85°CRH. 50V

168 Hrs, 85°C /60%RH+3IR-Reflow,

260°C +5V, -0°C

Pressure Cooker

JEDEC 22-A102C No Bias, 121°C,

100%RH 96Hrs/192Hrs.

168 Hrs, 85°C /60%RH+3IR-Reflow,

260°C +5V, -0°C

High Temp Storage

JESD 22-A103C Con B. 150°C, no bias 1000Hrs

HTRB

JESD 22-108C

168 Hrs, 85°C /60%RH+3IR-Reflow,

260°C +5V, -0°C

Thermal Shock

Mil-STD-883F, Method 1011.9 Condition

A, 0°C to 100°C

168 Hrs, 85°C /60%RH+3IR-Reflow,

260°C +5V, -0°C

C-SAM

As per flow, JSTD-020C pre&post

preconditioning test.

Wet Humidity

(Tin only)

JESD 201A standard: 55°C/85%RH

Notes:

1. All dimensions are in millimeters.

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. All specifications comply to JEDEC MO-178

5. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

6. Package surface matte tine

Physical Specifications

Lead Plating

SOT23: Matte Tin

Lead Material

Copper Alloy

Lead Coplanarity

0.0004 inches (0.102mm)

Subsitute Material

Silicon

Body Material

Molded Epoxy

Flammability

UL94-V-0