Varistor products, High energy industrial disc varistors > ca series, Hi–energy mo v’s – Littelfuse CA Varistor Series User Manual

Page 5

© 2013 Littelfuse, Inc.

185

Revised: May 8, 2013

Varistor Products

CA Varistor Series

High Energy Industrial Disc Varistors > CA Series

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/ca.html for current information.

HI–ENERGY

MO

V’S

CA Series

Passivation Layer

The standard CA Series is supplied with passivation

layer around the outside perimeter of the disc forming

an electrical insulator as detailed in the dimensional

drawing. For other options contact factory. (See Ordering

Information)

Encapsulated Recommendations

After lead attachment, the disc/lead assembly may be

coated or encapsulated in a package to provide electrical

insulation and isolation from environmental contamination

as required by the application. Coating/Filler materials for

containers may include silicones, polyurethanes, and some

epoxy resins. Materials containing halogens, sulfides, or

alkalines are not recommended.

Electrode Metallization

CA60 discs are supplied as standard with sintered Silver

electrodes. For other available options please contact

Littelfuse.

Stacking and Contact Pressure Recommendations

When applications require the stacking of CA60 discs,

or when an electrical connection is made by pressure

contacts, the pressure applied to the CA60 disc electrode

surface should be minimum 2.2kgs (5 pounds) and

maximum

4N/CM

2

(5.7LBs/IN

2

).

Part Numbering System

VARISTOR DESIGNATOR

MAX AC

RMS

WORKING VOLTAGE

(FIRST SIGNIFICANT DIGITS) V

M(AC)

DISC SIZE (mm) DIAMETER

SERIES DESIGNATOR

V

M(AC)

VOLTAGE DECADE MULTIPLIER

V 25 1 CA 60

Packaging and Shipping

The CA Series is supplied in bulk for shipment. Discs are

packaged in compartmentalized cartons to protect from

scratching or edge-chipping during shipment.

No branding or any other type of marking appears on the

CA disc itself.

CA60 discs are supplied as standard with sintered Silver

electrodes and glass passivation. For other available

options please contact factory.

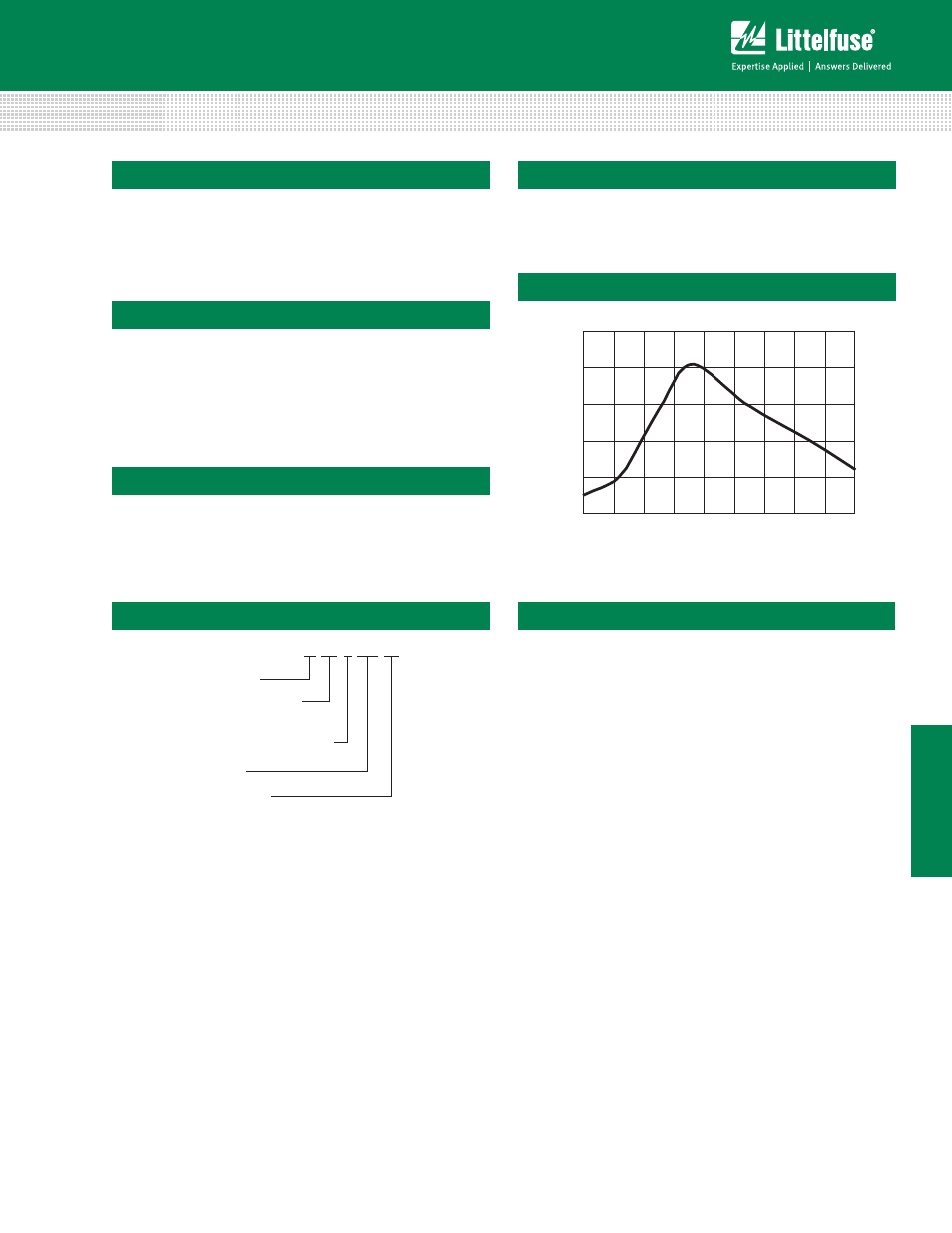

TEMPER

A

TURE (

o

C)

250

200

150

100

50

0

0

100

200

300

400

500

600

700

800

900

TIME (SEC)

Recommended Reflow Temperature Profile