Ingalls 93050 User Manual

Ingalls For the car

© Ingalls Engineering Co., Inc. - 2011 Cherry Street, Suite 104 - Louisville, CO, 80027

(800) 641-9795 - (303) 665-7800 - Fax: (303) 665-7810 - www.IngallsEng.com

Installation Instructions for 93050

Ingalls Engineering Stiffy ™ Engine Torque Damper for 2000-2006 Jeep Wrangler 4.0L-I6

The Stiffy ™ Adjustable Engine Torque Damper is engineered to reduce deflection under hard acceleration and cornering for

improved performance and power to weight transfer. Deflection in the motor mounts, as with the chassis and suspension, is a

formidable enemy in power and weight transfer, robbing valuable horsepower and control. The innovative, built-in damper eliminates

the huge amounts of “torque shock” that result from wheel-hop and once installed; transfers more power to the road and improves

acceleration, shifting, and overall control and balance. The adjustable feature allows the assembly to be tuned and pre-loaded for

performance and street applications.

CAUTION: Observe proper safety and repair procedures for installation of all chassis parts. Some chassis parts require

specialized tools and experience and therefore MUST be installed by a qualified technician; otherwise and unsafe vehicle and/or

personal injury could result. Wear safety glasses and other protection.

WARNING: Before beginning, check for any damaged or loose suspension connections. Loose connections here indicate worn

or broken parts which MUST BE REPLACED. Failure to replace a damaged or worn spindle and/or link may cause the wheel to

separate from the vehicle, possibly resulting in serious personal injury. Installer MUST check for proper clearance. Modification(s)

may be required. Please proceed ONLY if the vehicle owner is completely aware of these potential suspension modifications.

Estimated Installation Time: One Hour

Technical Rating: Easy

Included Parts List:

Required

Tools

for

Installation:

1 - Stiffy ™ Engine Torque Damper

Metric Sockets

1

-

Engine

Bracket

Metric

Box

Wrenches

1 - Shock Tower Bracket

Crescent Wrench (up to 27mm)

1

-

Hardware

Kit

Drill

&

13/32”

bit

3/8” Socket Driver (Wrench)

Step 1: Under the hood, locate and remove the air filter box top, filter and box bottom by removing the 3 bolts that

secure the box to the right side fender. Remove the right front shock and turn the wheels all the way to the left for

access to the right side shock tower.

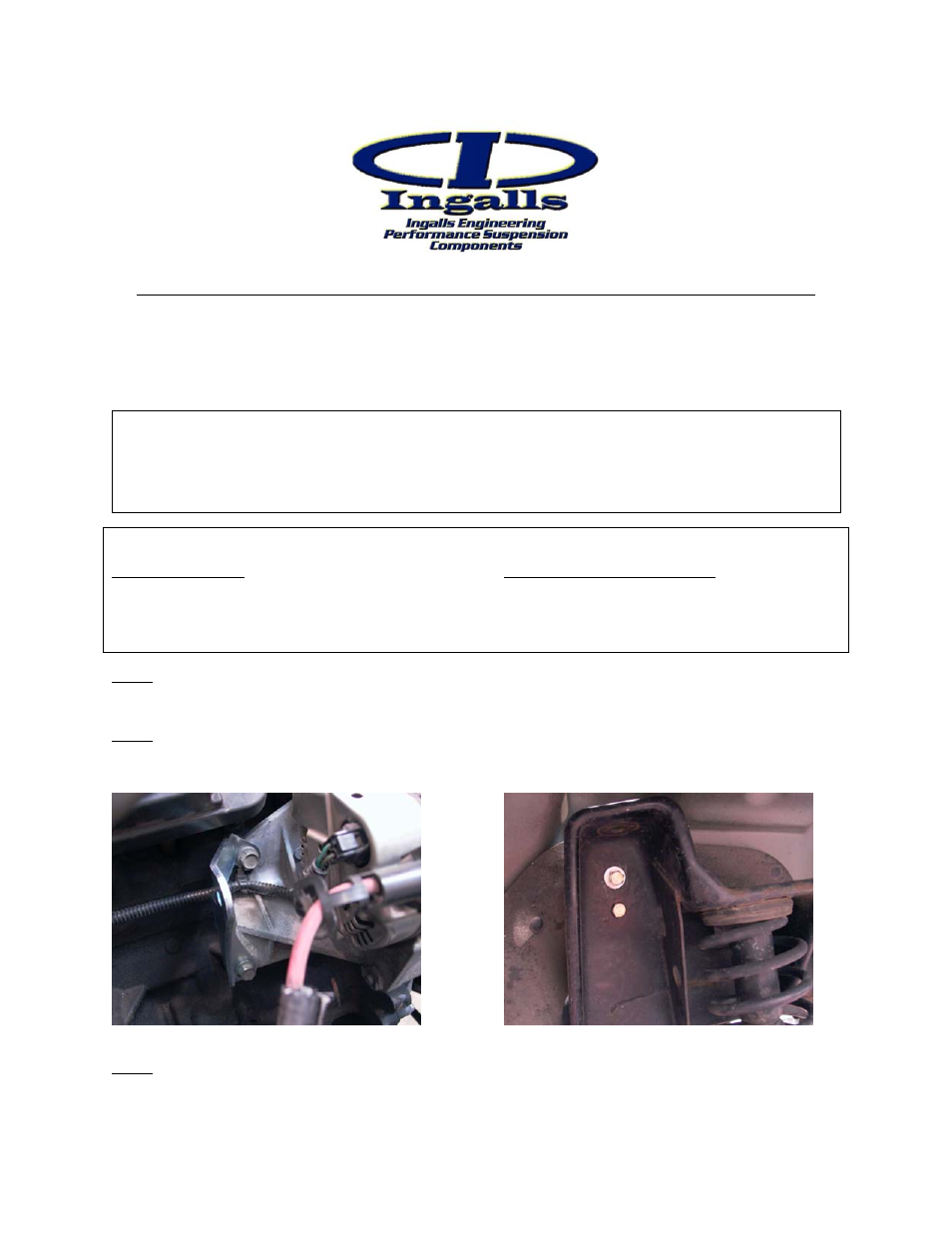

Step 2: Locate the two rearmost bolts on the alternator bracket and remove. Install the Stiffy

™ engine bracket using

the OEM bolts and tighten. FIGURE 1

FIGURE 1

FIGURE 2

Step 3: Find the oval hole on the right front shock tower near the top. A splash seal should cover the engine side of

the hole. Cut a slot in the splash shield about 1 ½” wide to about 2” below the oval hole with a knife.