Ingalls 38600-38620 User Manual

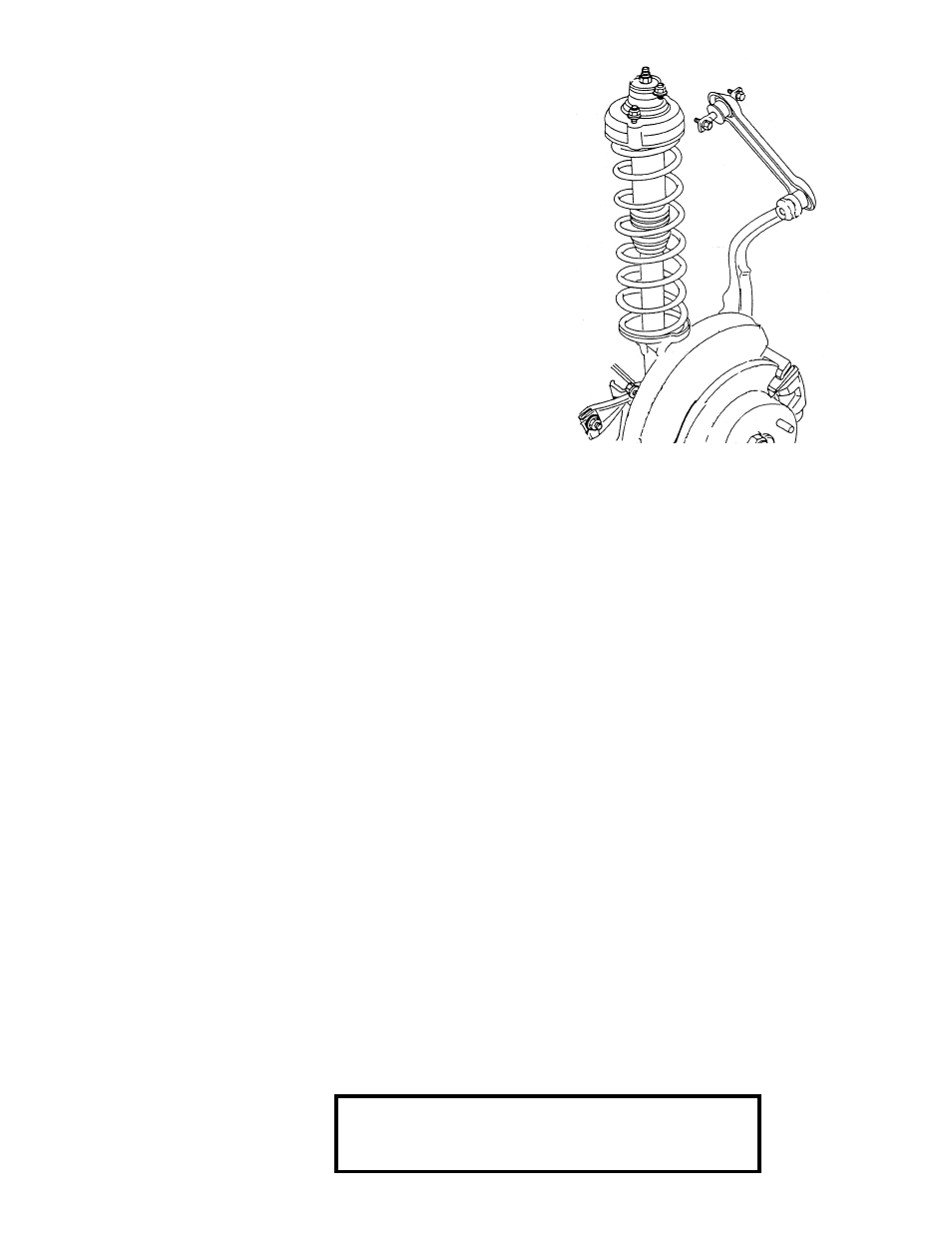

And possible damage to the vehicle, Replace rear upper control arm

Product Installation Instructions

ING3860-011300

Part Number 3860/3862

Note: To minimize possible noise characteristics of polyurethane bushings,

always lube with anti-seize before installation.

1. Before starting alignment, complete inspection checklist and determine

the amount of change needed.

2. Ensure both jam nuts are threaded all the way against the center hex of

the adjustment bolt. Assemble SmartArm

TM

by advancing both tubular

pieces equally until threads of the adjustment bolt are no longer visible.

Be sure to match left and right hand threads of all parts.

3. Raise the rear of vehicle and support body on jack stands. Remove rear

tire and wheel assembly.

4. Remove the two bolts from the inner end of the upper support arm at

the body mounting bracket.

5. Remove the nut from the ball joint at the upper support arm. Using a ball

joint separator or similar method, separate the ball joint taper and remove

the support arm. Take care to not damage threads of ball joint.

6. Remove the clip ring (if equipped) and rubber boot from the ball joint.

Inspect ball joint taper for signs of wear and replace if necessary.

7. Using a press or suitable method, press out the ball joint from the OE

support arm. Use care when removing the ball joint so threads are not

damaged and grease is not contaminated.

8. Using a press or suitable method, press the ball joint into the SmartArm

TM

from the top with the opening in the SmartArm

TM

angled slightly downwards.

WARNING: IMPROPER BALL JOINT INSTALLATION WILL RESULT IN DAMAGE OR BREAKAGE

OF THE NEW SmartArm

TM

AND POSSIBLE DAMAGE TO THE VEHICLE.

9. Reinstall the clip ring and boot on the ball joint.

10. Install the new SmartArm

TM

onto the body using the two original mounting bolts and torque to 28 ft. lbs. (38 N.M.).

11. Install the ball joint stud into the spindle, torque ball joint nut to 29-35 ft. lbs. (39-47 N.M.).

12. Replace the tire and wheel assembly.

13. Adjust camber by loosening jam nuts and turning the adjusting bolt to the desired specifications. DO NOT exceed more than 3/4”

(19mm) of exposed threads on either side of bolt.

14. Place a wrench or vice grips on the flat of the tube next to ball joint. While using the wrench to keep the ball joint body

perpendicular to the ball joint stud, tighten the jam nuts on the adjusting bolt.

15. Finish tightening the jam nuts by holding the adjusting bolt and verify that the ball joint is still aligned properly at the spindle.

Set rear toe to specifications.

WARNING: INCORRECT BALL JOINT ALIGNMENT WILL RESULT IN DAMAGE OR BREAKAGE OF

THE NEW SmartArm

TM

AND POSSIBLE DAMAGE TO THE VEHICLE

Limited Warranty

Subject to Disclaimer. All Ingalls products are warranted against defects in materials and workmanship for ninety (90) days from date of purchase. During the warranty period, Ingalls will repair, or at its option

replace at no charge, components that prove to be defective. The product must be returned, shipping prepaid, to Ingalls facility. This limited warranty does not apply if the product is damaged by accident or misuse.

The foregoing warranty is in lieu of all other warranties expressed or implied including but not limited to any implied warranty of merchantability, fitness, or adequacy for any particular purpose or use Ingalls shall

not be liable for any special, incidental or consequential damages whether in contract, tort, or otherwise resulting from the use of or the inability to use the product.

WARRANTY DISCLAIMER

Use of this product in competition, or use on vehicles altered from original manufacturer's specifications or settings, EXPRESSLY VOIDS WARRANTY. The user is urged to inspect for suspension binding or

interference when the product is used in these manners. However, due to the varying conditions and manner of use which the priduct will be subjected to in such uses, Ingalls Engineering Co., Inc. makes no

warranties, either express or implied, including any warranty of merchantability or fitness for a particular purpose for use in competition or with specifications or setting other than those specified by the original

manufacturer's specifications.

Copyright

©

2000 Ingalls Engineering Co., Inc.

Replace rear upper

control arm

To minimize possible noises characteristic of polyurethane

bushings, always lube before installation. To avoid

inherent polyurethane noises use the rubber bushing

version. See catalog for part number.