Ingalls 38420 User Manual

Ingalls, And possible damage to the vehicle

Ingalls

Product Installation Instructions

ING38420-051804

Part Number 38420

CAUTION: Observe proper safety and repair procedures for installation of all chassis parts. Some chassis parts require specialized tools and

experience and therefore MUST be installed by a qualified technician otherwise an unsafe vehicle and/or personal injury could result. Wear safety

glasses and other protection.

WARNING: Before beginning, check for any damaged or loose suspension connections. Loose connections here indicate worn or broken parts which

MUST BE REPLACED. Failure to replace a damaged or worn spindle and/or link may cause the wheel to separate from the vehicle, possibly resulting in

serious personal injury.

NOTE: These parts are intended for use in vehicles with abnormal alignment and are designed to replace the non-adjustable factory equipment. These

parts are not designed for installation on vehicles with suspension and/or steering systems modified for racing, competition or any other non-standard

purpose.

Before starting alignment, complete inspection checklist and determine the amount of change needed.

1.

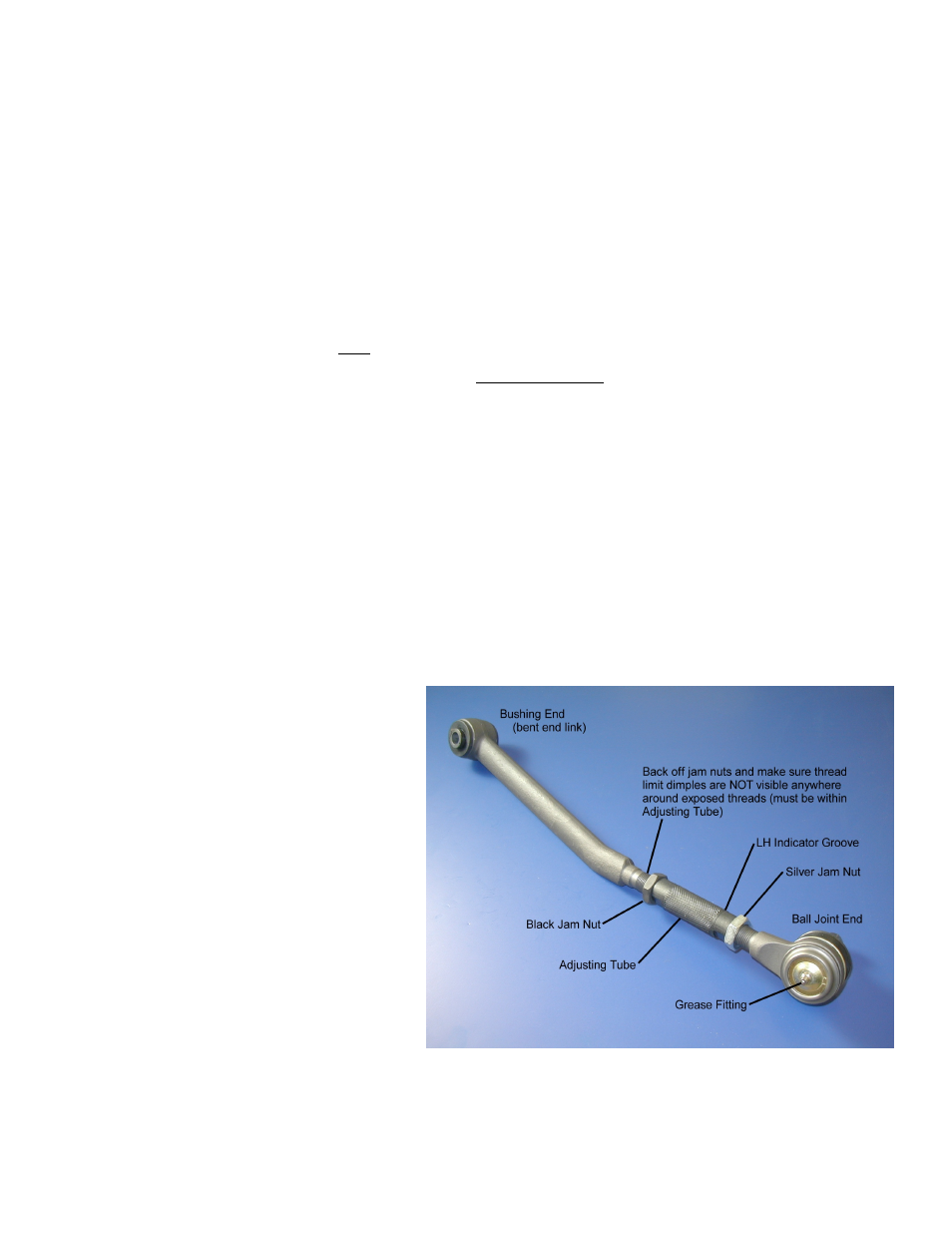

Match left and right hand threaded parts and assemble the SmartArm

TM

. Thread the Jam Nuts all the way down on the End Links [left hand Jam

Nut (silver) on the left hand threaded ball joint end link, right hand Jam Nut (black) on the right hand threaded bent end link]. Thread the End Links

into the Adjusting Tube (put the left hand ball joint End Link into the end of the Adjusting Tube which has the radial groove next to the wrench flats).

2.

Raise the rear of the vehicle and support the body safely on jack stands. Remove the rear tire and wheel assembly.

3.

Remove the bolt from the inner end of the OE upper support arm at the body mounting bracket. Save the bolt to re-install the new arm.

4.

Remove the nut from the ball joint at the upper support arm. Using a ball joint separator or similar method, separate the ball joint taper and remove

the support arm (strong hammer blows to the outside of the taper joint, not the ball joint or stud, will break the taper loose).

5.

Install the new SmartArm

TM

unit in the same manner as the OE support arm. With the bend in the arm pointing down, place the bushing end into

the body mounting bracket and insert the OE bolt (do not tighten yet). Rotate the ball joint around so it can be inserted into the wheel hub in the

same direction as the OE ball joint was so the ball joint stud taper matches the hub taper. Tighten the ball joint nut and torque to 44-53 Ft-Lbs (60-

72 N-m).

6.

Safely raise the wheel hub close to its normal ride position in the wheel well to properly set the rubber bushings (do not raise the body off the jack

stands for safety).

7.

Set the OE cam bolt to its neutral position (this adjustment can be used later if necessary) and tighten to 103-118 Ft-Lbs (140-160 N-m).

8.

Replace the tire and wheel assembly (torque lug nuts to factory specifications).

9.

Adjust camber by loosening the jam nuts and turning the Adjusting Tube to the desired specifications. DO NOT extend the threads beyond their

limits (ensure that the dimple marks on the End Link threads are still located within the Center Tube).

10. Important - Place a wrench or vice grips on the flat section of the ball joint end. While using the wrench to keep the ball joint body perpendicular to

the ball joint stud, tighten the jam nuts against the Adjustment Tubes to 80 ft. lbs. [108 N.M.]. Make sure the ball joint body does not move when

tightening the jam nuts, it must be aligned properly to allow the full range of motion intended by the factory.

WARNING: INCORRECT BALL JOINT ALIGNMENT WILL RESULT IN DAMAGE OR BREAKAGE

OF THE NEW SmartArm

TM

AND POSSIBLE DAMAGE TO THE VEHICLE

11.

Important - Install the grease fitting into the ball joint cap and completely fill ball joint with axle grease until grease extrudes out the ball joint boot.

12.

Follow the factory instructions to adjust rear toe to the desired specifications. Re-adjust camber if necessary.

13.

Check for proper suspension clearance (see note below), road test vehicle and re-adjust alignment as necessary.

ALWAYS CHECK FOR SUSPENSION CLEARANCE

Modifying any suspension component may change other part

clearances and cause binding or interferences. After installing

any Ingalls’ product, the suspension must be checked for binds

or interference between all components, other arms and the

chassis. Be sure that all control arms, struts and steering ends

move freely through the full movement of the suspension

(springs may need to be removed to fully check component

travel). Installing any Ingalls’ product on a modified vehicle

(lowered or raised) from the original factory design requires a

detailed check of all suspension components and their

movements. Ingalls recommends that a trained technician

install all products.

Limited Warranty

Subject to Disclaimer. All Ingalls products are warranted against

defects in materials and workmanship for ninety (90) days from

date of purchase. During the warranty period, Ingalls will repair,

or at its option replace at no charge, components that prove to

be defective. The product must be returned, shipping prepaid,

to Ingalls facility. This limited warranty does not apply if the

product is damaged by accident or misuse. The foregoing

warranty is in lieu of all other warranties expressed or implied

including but not limited to any implied warranty of

merchantability, fitness, or adequacy for any particular purpose

or use. Ingalls shall not be liable for any special, incidental or

consequential damages whether in contract, tort, or otherwise

resulting from the use or the inability to use the product.

Warranty Disclaimer

Use of this product in competition, or use on vehicles altered from original manufacturer’s specifications or settings, EXPRESSLY VOIDS WARRANTY.

The user is urged to inspect for suspension binding or interference when the product is used in these manners. However, due to the varying conditions

and manner of use which the product will be subjected to in such uses, Ingalls Engineering Co., Inc. makes no warranties, either express or implied,

including any warranty of merchantability or fitness for a particular purpose for use in competition or with specifications or settings other than those

specified by the original manufacturer’s specifications.

Copyright ©2004 Ingalls Engineering Co., Inc.