Ingalls 53500 User Manual

Camber, Negative- +positive, Chart

Installation Instructions

1. Remove the upper ball joint cotter pin and nut.

2. To help prevent a tight steering condition and aid in the

seating of the New bushing, remove the lower ball joint cotter

pin and loosen the nut, but do not remove.

3. Strike the inside of the spindle near the upper and lower ball

joints to break the spindle loose from the ball joint studs.

4. Remove the old bushing using a puller or similar tool.

5. Install a 0° bushing and tighten the lower ball joint stud to 40

ft. lbs. Take new readings then determine camber/caster

changes needed.

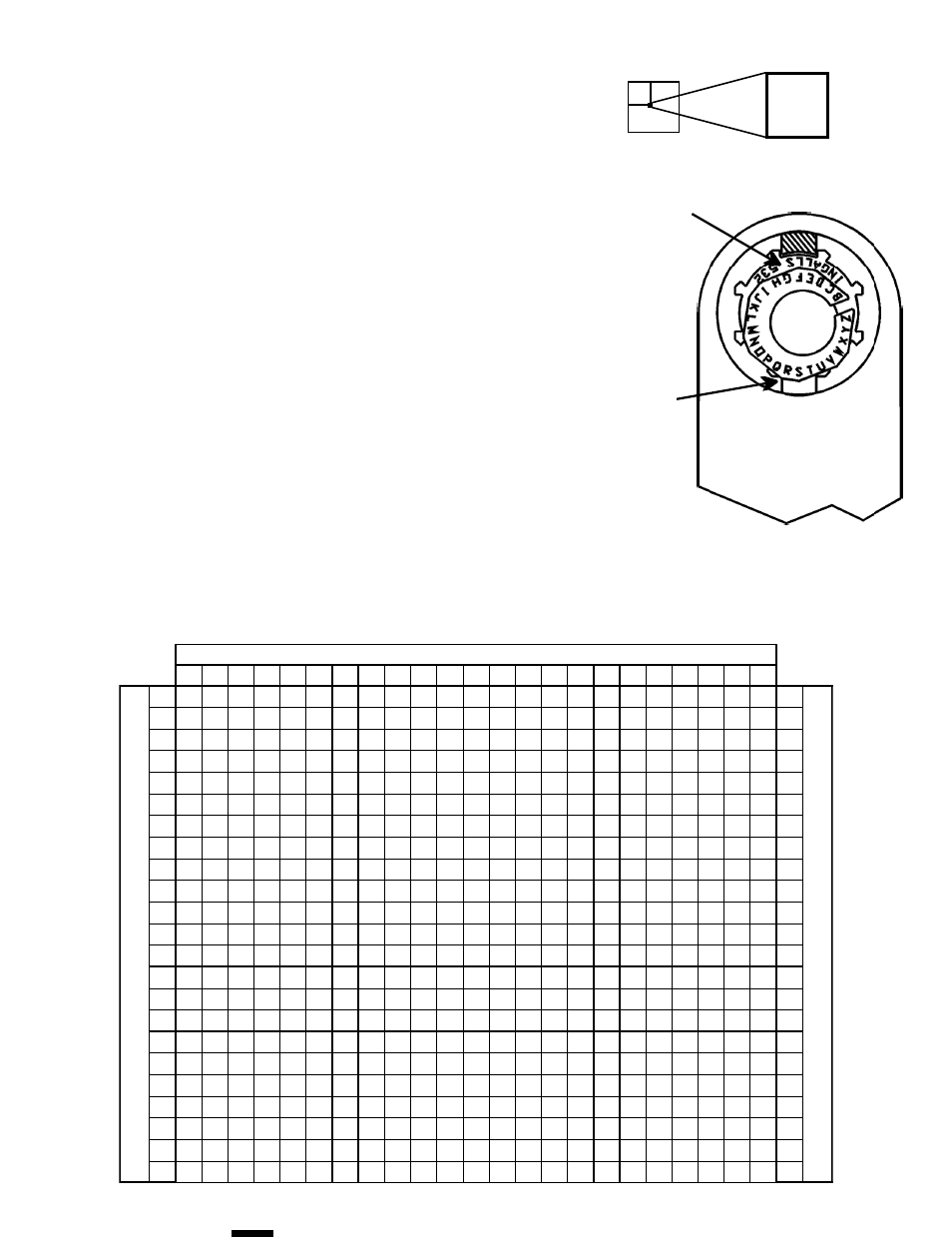

6. Find camber change needed at the top of the chart.

7. Find caster change needed. For driver side use the

left side of chart, for passenger side use the right side.

8. Follow the desired measurements to their intersection. In this

box you will find two letters. The upper letter is the inner piece

adjustment. The lower letter is for the installation reference

point.

9. Adjust the inner piece so that the top letter(s) found on chart

is centered with slot of the outer piece.

10. Remove 0° bushing.

11. Install the bushing so that the lower letter found on the chart

is lined up with the dog or flat located closest to the wheel.

12. Install the upper ball joint stud nut and torque to 85-95 ft lbs.

13. Finish torquing the lower ball joint stud nut to 95-110 ft lbs.

14. Set toe and recheck alignment.

Why use a 0° bushing: Some Ford trucks come from the factory with an offset bushing already

installed. Not all of these bushings are clearly marked. Using the 0° bushing eliminates math

errors when calculating the proper adjustment needed.

Patent No. 4,420,272

ING535-092099

caster

camber

S

F

Chart

Upper Letter

Lower Letter

Example Setting

Only!!!

-NEGATIVE-

+POSITIVE+

CAMBER

+

P

O

S

+

C

A

S

T

E

R

-

N

E

G

-

-

N

E

G

-

C

A

S

T

E

R

+

P

O

S

+

D

R

I

V

E

R

S

I

D

E

P

A

S

S

E

N

G

E

R

S

I

D

E

S lined up with slot

in outer bushing

F is lined up with

the dog located

nearest to the

wheel.

2 3/4° 2 1/2° 2 1/4°

2°

1 3/4° 1 1/2° 1 1/4°

1°

3/4°

1/2°

1/4°

0°

1/4°

1/2°

3/4°

1°

1 1/4° 1 1/2° 1 3/4°

2°

2 1/4° 2 1/2° 2 3/4°

2 3/4°

N

G-H

2 3/4°

2 1/2°

L

E-F

L-M

F

M-N

G

N-O

H

O-P

I

P

I-J

2 1/2°

2 1/4°

O-P

E-F

P

F

K-L

E

Q

G

R

H

R-S

H-I

I-J

F

J

F-G

J-K

G

K-L

H

P-Q

J

L-M

I

M

I-J

2 1/4°

2°

N-O

D-E

J

C-D

J-K

D

H

D-E

H-I

E

T

J

T-U

J-K

Q-R

K

R

K-L

N

J-K

2°

1 3/4°

N

D

I-J

C

S-T

F-G

T-U

G-H

U

H

U-V

H-I

F-G

F-G

G

G

G-H

G-H

H-I

H-I

R-S

L

N-O

K

1 3/4°

1 1/2°

M

C

M-N

C-D

R-S

E-F

I

B-C

F-G

C

G

C-D

V

I

E-F

E-F

F

F

U-V

K-L

V

L

I

I

I-J

I-J

O

K-L

O-P

L

1 1/2°

1 1/4°

L-M

B-C

Q-R

D-E

H-I

B

F

B-C

D

D

D-E

D-E

W-X

J-K

X

K

V-W

L-M

S-T

M

J-K

J-K

P

L-M

1 1/4°

1°

L

B

G-H

A

V

E-F

V-W

F

E-F

B

W-X

G

C-D

C-D

Y

H-I

C

F

C-D

F-G

X-Y

K-L

E

H

W

M

F

I

F-G

I-J

T-U

N

K-L

K-L

1°

3/4°

P

C

K-L

A-B

G

Z-A

U-V

E

E

A-B

Z

F-G

Z-A

G

A

G-H

A-B

H

B

H-I

W-X

M-N

G

J

U

N-O

Q

M-N

L

L

3/4°

1/2°

O-P

B-C

J-K

Z-A

T-U

D

F-G

Z

X

D-E

X-Y

E

A

D

Z

M

C-D

J

D

J-K

U-V

O

H

K

R

N-O

L-M

L-M

1/2°

1/4°

N-O

A-B

J

Z

T

C-D

F

Y-Z

W-X

D

C-D

Z

Z-A

C-D

Z-A

M-N

Y

O

D-E

K

V

O-P

H-I

K-L

R-S

O

M-N

M-N

1/4°

0°

N

A

I-J

Y-Z

E-F

Y

C

Y-Z

A

A

A

N

Y-Z

O-P

E

K-L

S

O-P

N

N

0°

1/4°

M-N

Z-A

R-S

B

H-I

X-Y

V

B-C

D-E

X

Y

B

B

X-Y

Z-A

P-Q

C-D

M

W-X

Q

F

L-M

T

P-Q

J

M

N-O

N-O

1/4°

1/2°

M

Z

R

A-B

H

X

U-V

B

D

W-X

C-D

W

A-B

X

B

O

X-Y

R

X

Q-R

F-G

M

T-U

Q

J-K

M-N

O-P

O-P

1/2°

3/4°

L

Y

Q

Z-A

U

A-B

G

W

W-X

Z-A

B

U-V

A-B

U

A

T-U

Z-A

T

A-B

Q-R

E

N-O

U-V

R

G

M-N

K-L

N-O

P

P

3/4°

1°

K-L

X-Y

T-U

A

F-G

V-W

F

V

W

Z

E

U

X-Y

X-Y

C-D

S-T

Y-Z

V

Y

U-V

C-D

P-Q

W-X

T

E-F

O

V-W

S

V

R-S

G-H

N

P-Q

P-Q

1°

1 1/4°

P

Y-Z

J-K

W-X

S-T

Z

V-W

Y-Z

X

X

W-X

W-X

D-E

Q-R

D

Q

F

O-P

H-I

O

Q-R

Q-R

L-M

O-P

1 1/4°

1 1/2°

O-P

Y

O

X-Y

I-J

V-W

S

Y-Z

V

Y

U-V

X-Y

F

S

E

R

V

V

G

P-Q

F-G

P

S

S

R-S

R-S

M-N

P-Q

M

P

1 1/2°

1 3/4°

N-O

X

R-S

Y

H-I

U-V

G-H

T-U

G

T

F-G

S-T

U-V

U-V

U

U

T-U

T-U

S-T

S-T

I-J

P

N

Q

1 3/4°

2°

N

W-X

R

X-Y

Q-R

X

T-U

W-X

T

W

H-I

R

H

Q-R

J-K

Q

J

P-Q

N-O

Q-R

2°

2 1/4°

M

V-W

L-M

V

P-Q

W

K-L

U

J-K

T

J

S-T

S

V

R-S

U-V

R

U

Q

T

K-L

R

P

S

O-P

R-S

2 1/4°

2 1/2°

P

V-W

O-P

V

N-O

U

M-N

T

M

S-T

L

R-S

2 1/2°

2 3/4°

N

T-U

2 3/4°

Copyright © 1999 Ingalls Engineering Co., Inc.