Ingalls 38525 User Manual

Page 2

Ingalls Engineering Co., Inc. ● 2011 Cherry Street, Suite 104 ● Louisville CO 80027

(800) 641-9795 ● (303) 665-7800 ● Fax: (303) 665-7810 ● www.ingallseng.com

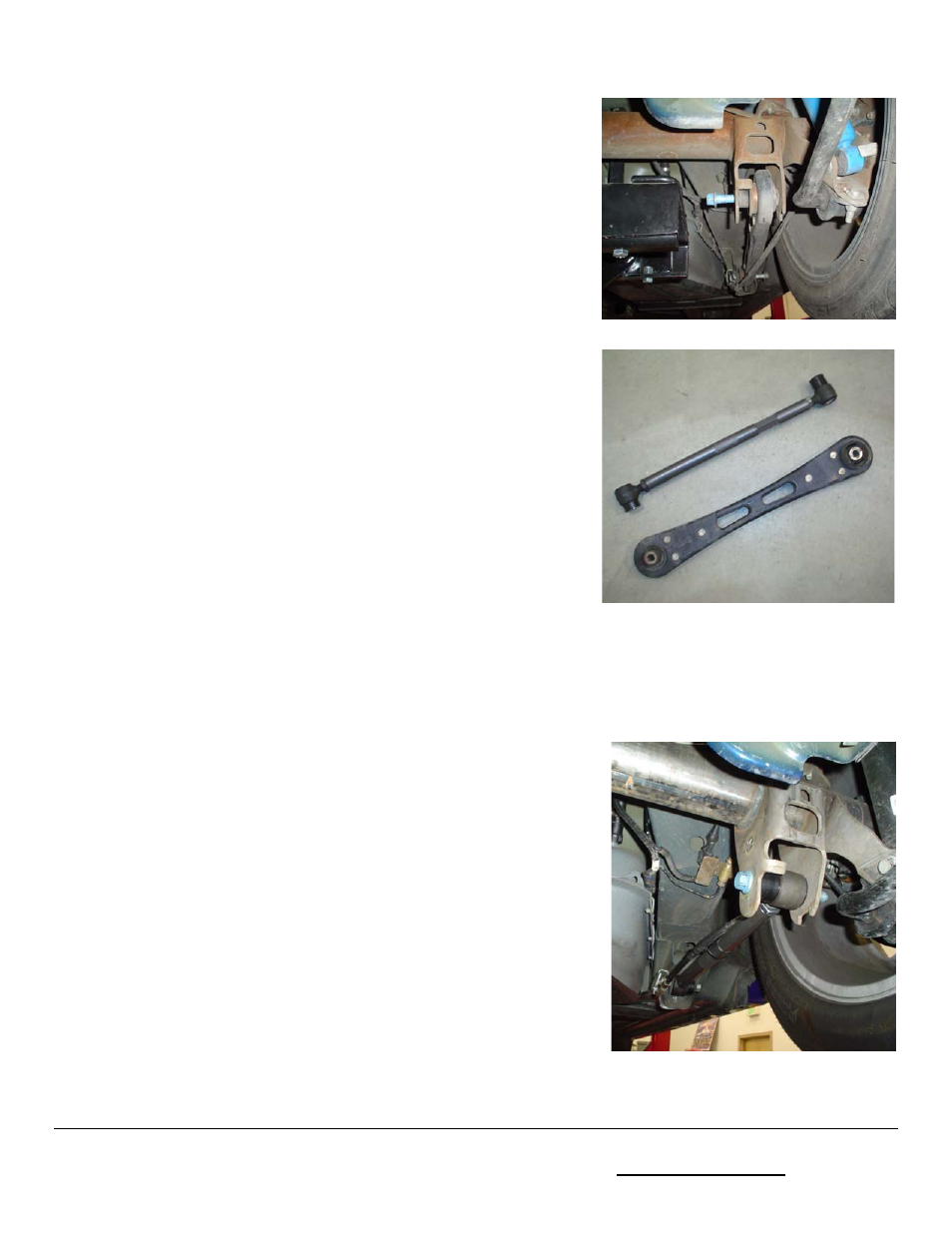

Step 2: Remove the 14mm bolts at each end of the control

arms. In almost every case the rear control arms are in a bind

and require some messaging for removal. If the car is on a

drive-on type of lift, you will be able to roll the car back and

forth, greatly aiding in the removal of the bolts. Needless to

say, a crow bar may come in handy when installing the

components in your garage at home on jack stands.

Step 3: With the control arms out of the car, begin to assemble

the new control arms by threading the forgings into the steel

tubes, which have right hand threads and left hand threads

allowing for a wide range of length adjustment. To make sure

the length is the same as the OEM control arm, you can slide

the bolts into the OEM arms to serve as a guide for the length

adjustment. You may want to tighten the jam-nuts before

installation, but make sure to keep the forged ends aligned

properly. You can also tighten the jam nuts after installation, but clearance is tight for the wrenches.

Once you have the assembly complete, apply a generous amount of the supplied bushing lube to

eliminate any noise from the polyurethane where it pivots against the mounting brackets.

Step 4: One important feature of the Ingalls control arms is the

offset bushings at each end. The bushings eliminate the “splay”

or angle of the arms in relation to the chassis, which dramatically

improves the performance of the complete package. The large

bushing is used at the axle housing, while the smaller bushing is

used at the chassis. In addition, the offset on the bushings are

opposite at each end and critical to the installation procedure.

Installation is a snap, but you may encounter fitment issues due

to the binding of the whole axle assembly. Rolling the car back

and forth as in step 1, will aid in the installation of the arms and

bolts. If you are not on a drive-on lift, you may have to message the axle assembly with a pry-bar to

remove some of the bind in the rear suspension.