Limited warranty – Ingalls 93037 User Manual

Page 2

Step 4: Align Stiffy™ Engine Torque Damper Bracket (with Ingalls logo) over the passenger side strut tower bar rear

mounting point and the inner most strut top stud. Place the supplied thin spacer on the other mounting point for the

strut tower bar and reinstall with the OE strut tower brace on top of the Stiffy™ bracket. Torque hardware to OE

specifications, or to no more than 20 ft-lbs. Also reinstall any aftermarket strut tower braces and the two remaining

passenger side strut top nuts. (See Figure 1, Arrows A)

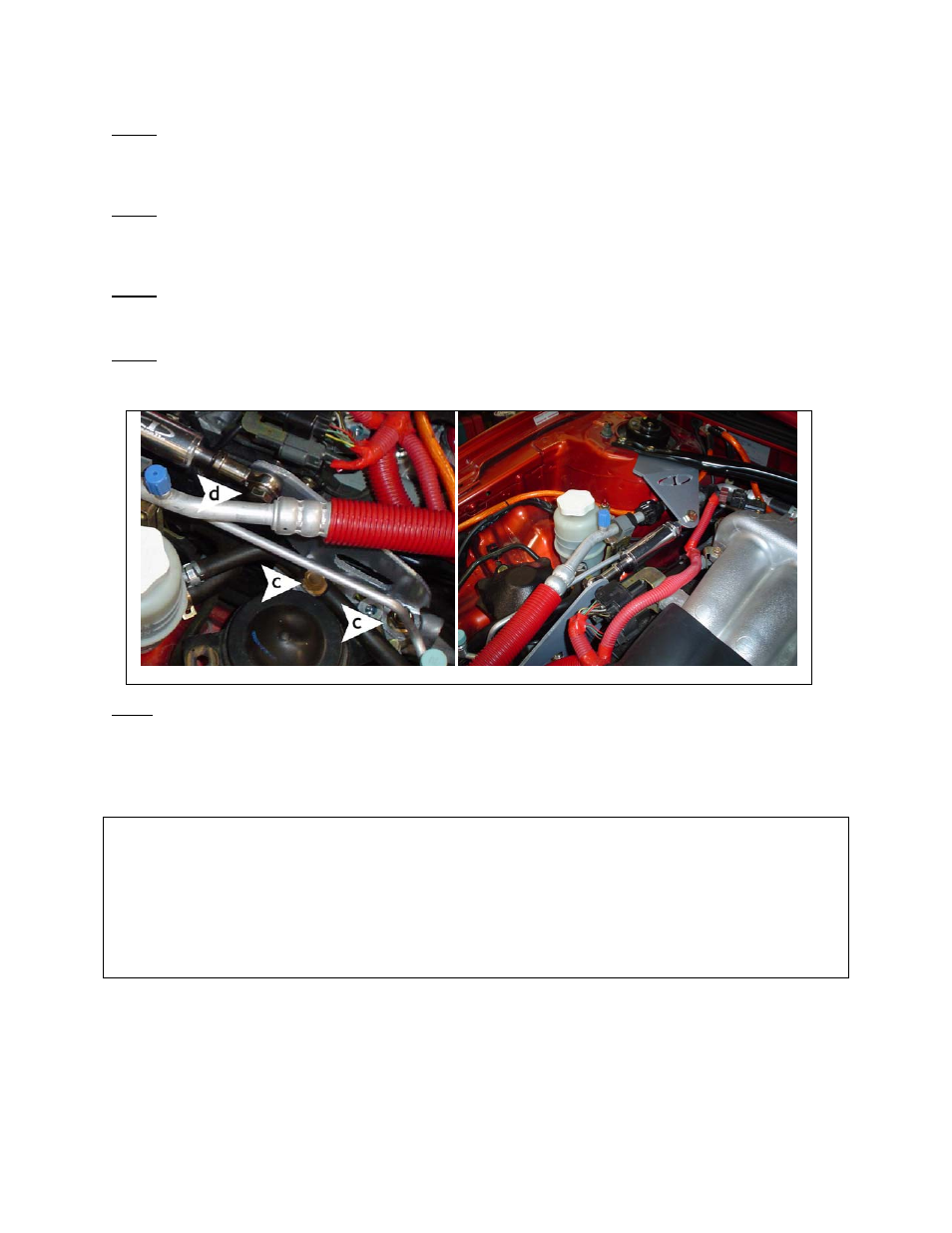

Step 5: Align and install the remaining Stiffy™ ETD bracket over the factory engine mount. While installing place OE

cross brace through the hole in the bracket in the same orientation as it was removed. Install hardware for the cross

brace and then torque to OE specifications; no more than 15 ft-lbs. (See Figure 2, Arrow B) Reinstall engine mount

hardware and torque to OE specifications (65-70ft-lbs), check to ensure that Stiffy™ bracket is flush with mount

surface. (See Figure 3, Arrows C)

Step 6: Adjust Stiffy™ Engine Torque Damper to the desired stiffness (see www.ingallseng.com for preload

adjustment procedure) and then adjust the length to match the two mounting points on the Stiffy™ brackets. The

mounting points are approximately 7 inches center-to-center, therefore the Stiffy™ will need to measure the same

distance. (See Figures 1 and 3, Arrows D)

Step 7: Install Stiffy™ ETD using supplied hardware in the following order; Bolt, Stiffy™ end-link, o-ring, bracket,

washer, lock nut. This orientation is crucial for the reduction of ancillary vibrations. (See Figures 1 and 3, Arrows D)

(See Figure 4 for complete install image)

Figure

3

Figure

4

Notes:

Proper use and fitment of the rubber O-ring helps dampen additional road noise or “feel” that can be transferred through the damper

assembly. The O-ring should be used between the Stiffy ™ heim joint and bracket for optimal noise suppression. Dynamat or other

damping materials, as used in aftermarket audio and in-car electronics industries, can also be used to provide further noise and

vibration damping when used between the brackets and the surface they mount on.

DO NOT attempt to adjust Stiffy ™ from its pre-set stiffness without consulting the Ingalls website. Large open-end wrenches are

required to adjust stiffness (27mm). Most standard and mechanics tool kits do not include these types of wrenches.

Limited Warranty

Subject to Disclaimer. All Ingalls Engineering Co., Inc. products are warranted against defects in materials and workmanship for ninety (90) days from date of

purchase. During the warranty period Ingalls will repair, or at its option replace, at no charge components that prove to be defective. The product must be returned,

shipping prepaid, to Ingalls facility. This limited warranty does not apply if the product is damaged by accident of misuse. The foregoing warranty is in lieu of all

other warranties expressed or implied; including but not limited to any implied warranty of merchantability, fitness, or adequacy for any other particular purpose or

use. Ingalls shall not be liable for any special, incidental, or consequential damages whether in contract, tort, or otherwise resulting from the use or the inability to

use the product.

Warranty Disclaimer

Use of this product in competition, or use on vehicles altered from original manufacturer’s specifications or settings, EXPRESSLY VOIDS WARRENTY. The user is

urged to inspect for suspension binding or interference when the product is used in these manners. However, due to the varying conditions and manner of which

the product will be subjected to in such uses, Ingalls Engineering Co., Inc. makes no warranties, either express or implied, including any warranty of

merchantability or fitness for a particular purpose for use in competition or with specification or settings other than those specified by the original manufacturer’s

specifications.

© Ingalls Engineering Co., Inc. - 2011 Cherry Street, Suite 104 - Louisville, CO, 80027

(800) 641-9795 - (303) 665-7800 - Fax: (303) 665-7810 - www.IngallsEng.com