Ceramic output capacitor applications – Rainbow Electronics MAX1813 User Manual

Page 35

MAX1813

Dynamically-Adjustable, Synchronous Step-Down

Controller with Integrated Voltage Positioning

______________________________________________________________________________________

35

to V+ on the MAX1813, with the same attenuation factor

as the output divider. The V+ input has a nominal

600k

Ω input impedance, which should be considered

when selecting resistor values.

One-Stage (Battery Input) vs. Two-Stage

(5V Input) Applications

The MAX1813 can be used with a direct battery con-

nection (one stage) or can obtain power from a regulat-

ed 5V supply (two stage). Each approach has

advantages, and careful consideration should go into

the selection of the final design.

The one-stage approach offers smaller total inductor

size and fewer capacitors overall due to the reduced

demands on the 5V supply. The transient response of

the single stage is better due to the ability to ramp the

inductor current faster. The total efficiency of a single

stage is better than the two-stage approach.

The two-stage approach allows flexible placement due

to smaller circuit size and reduced local power dissipa-

tion. The power supply can be placed closer to the

CPU for better regulation and lower I

2

R losses from PC

board traces. Although the two-stage design has slow-

er transient response than the single stage, this can be

offset by the use of a voltage-positioned converter.

Ceramic Output Capacitor Applications

Ceramic capacitors have advantages and disadvan-

tages. They have ultra-low ESR and are noncom-

bustible, relatively small, and nonpolarized. However,

they are also expensive and brittle, and their ultra-low

ESR characteristic can result in excessively high ESR

zero frequencies. In addition, their relatively low capac-

itance value can cause output overshoot when step-

ping from full-load to no-load conditions, unless a small

inductor value is used (high switching frequency) or

there are some bulk tantalum or electrolytic capacitors

in parallel to absorb the stored inductor energy. In

some cases, there may be no room for electrolytics,

creating a need for a DC-DC design that uses nothing

but ceramics.

The MAX1813 can take advantage of the small size and

low ESR of ceramic output capacitors. To ensure stable

operation, there must be sufficient resistance in series

with the inductor and output capacitor (see “Output

Capacitor Stablility Considerations”).

Output overshoot (V

SOAR

) determines the minimum

output capacitance requirement (see Output Capacitor

Selection). Often the switching frequency is increased

to 1000kHz or 600kHz, and the inductor value is

reduced to minimize the energy transferred from induc-

tor to capacitor during load-step recovery. The efficien-

cy penalty for operating at 1000kHz is about 5% and

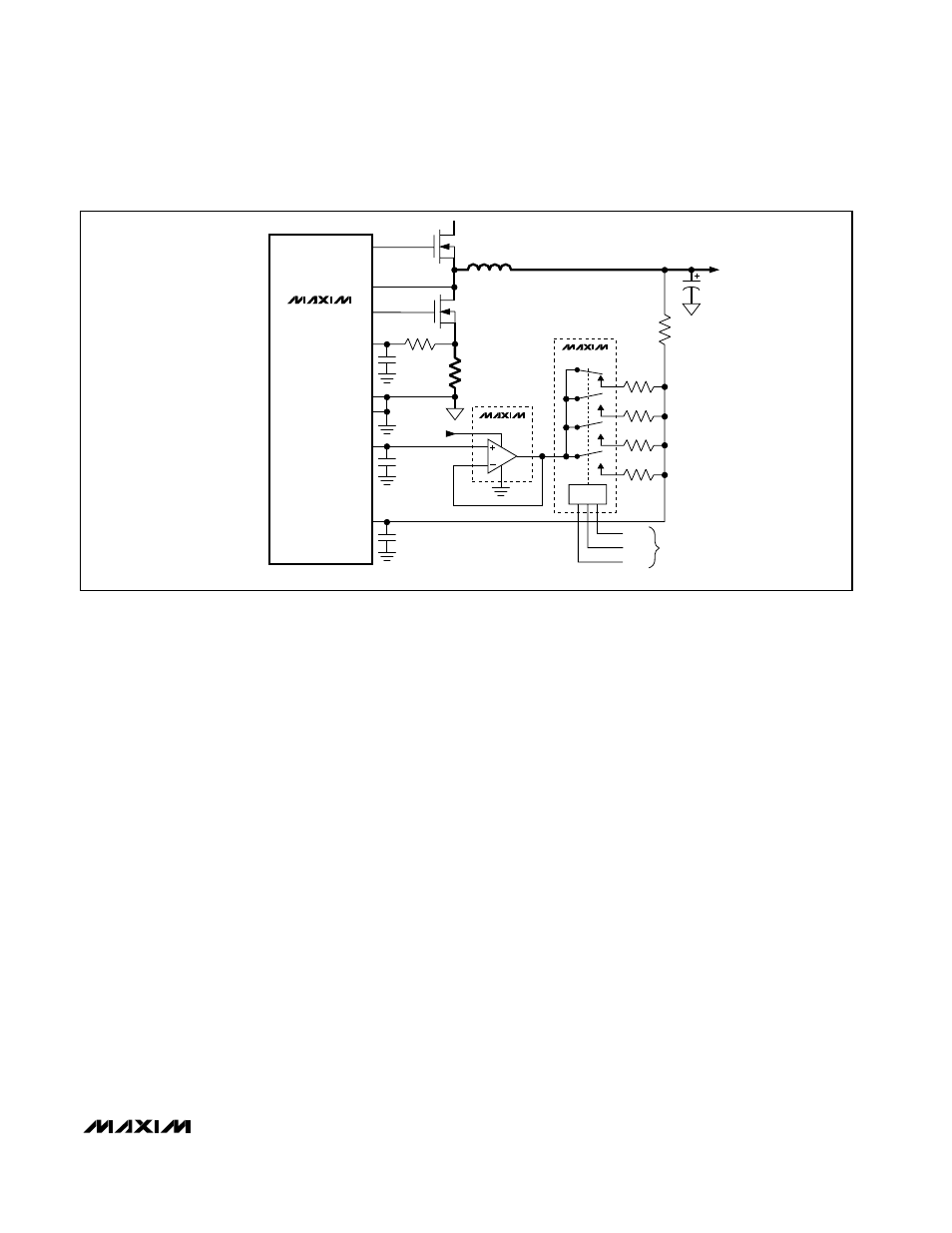

MAX1813

DH

LX

VPCS

PGND

DL

GND

REF

FB

V

OUT

C

OUT

Q

2

C

FB

C

VPCS

R

VPCS

Q

1

R

FB

R5

R6

R7

LOGIC

ADD0

ADD1

CONTROL

LOGIC

INH

R8

L1

R

SENSE

C

REF

V

CC

MAX4634

MAX4322

Figure 18. Adding a Negative Offset Voltage