Design procedure – Rainbow Electronics MAX17031 User Manual

Page 19

Power-Good Outputs (PGOOD)

and Fault Protection

PGOOD is the open-drain output that continuously

monitors both output voltages for undervoltage and

overvoltage conditions. PGOOD is actively held low in

shutdown (ON1 or ON2 = GND), during soft-start, and

soft-shutdown. Approximately 20µs (typ) after the soft-

start terminates, PGOOD becomes high impedance as

long as both output voltages exceed 85% of the nomi-

nal fixed-regulation voltage. PGOOD goes low if the

output voltage drops 15% below the regulation voltage,

or if the SMPS controller is shut down. For a logic-level

PGOOD output voltage, connect an external pullup

resistor between PGOOD and the logic power supply.

A 100k

Ω pullup resistor works well in most applications.

Overvoltage Protection (OVP)

When the output voltage rises 15% above the fixed-

regulation voltage, the controller immediately pulls

PGOOD low, sets the overvoltage fault latch, and imme-

diately pulls the respective DL_ high—clamping the

output fault to GND. Toggle either ON1 or ON2 input, or

cycle V

CC

power below its POR threshold to clear the

fault latch and restart the controller.

Undervoltage Protection (UVP)

When the output voltage drops 30% below the fixed-

regulation voltage, the controller immediately pulls the

PGOOD low, sets the undervoltage fault latch, and

begins the shutdown sequence. After the output volt-

age drops below 0.1V, the synchronous rectifier turns

on, clamping the output to GND regardless of the out-

put voltage. Toggle either ON1 or ON2 input, or cycle

V

CC

power below its POR threshold to clear the fault

latch and restart the controller.

Thermal-Fault Protection (T

SHDN

)

The MAX17031 features a thermal-fault protection cir-

cuit. When the junction temperature rises above

+160°C, a thermal sensor activates the fault latch, pulls

PGOOD low, enables the 10

Ω discharge circuit, and

disables the controller—DH and DL pulled low. Toggle

ONLDO or cycle IN power to reactivate the controller

after the junction temperature cools by 15°C.

Design Procedure

Firmly establish the input-voltage range and maximum

load current before choosing an inductor operating

point (ripple-current ratio). The primary design goal is

choosing a good inductor operating point, and the fol-

lowing three factors dictate the rest of the design:

•

Input Voltage Range: The maximum value (V

IN(MAX)

)

must accommodate the worst-case, high AC-

adapter voltage. The minimum value (V

IN(MIN)

)

must account for the lowest battery voltage after

drops due to connectors, fuses, and battery-selec-

tor switches. If there is a choice at all, lower input

voltages result in better efficiency.

•

Maximum Load Current: There are two values to

consider. The peak load current (I

LOAD(MAX)

) deter-

mines the instantaneous component stresses and fil-

tering requirements and thus drives output capacitor

selection, inductor saturation rating, and the design of

the current-limit circuit. The continuous load current

(I

LOAD

) determines the thermal stresses and thus dri-

ves the selection of input capacitors, MOSFETs, and

other critical heat-contributing components.

MAX17031

Dual Quick-PWM Step-Down Controller with Low-

Power LDO and RTC Regulator for MAIN Supplies

______________________________________________________________________________________

19

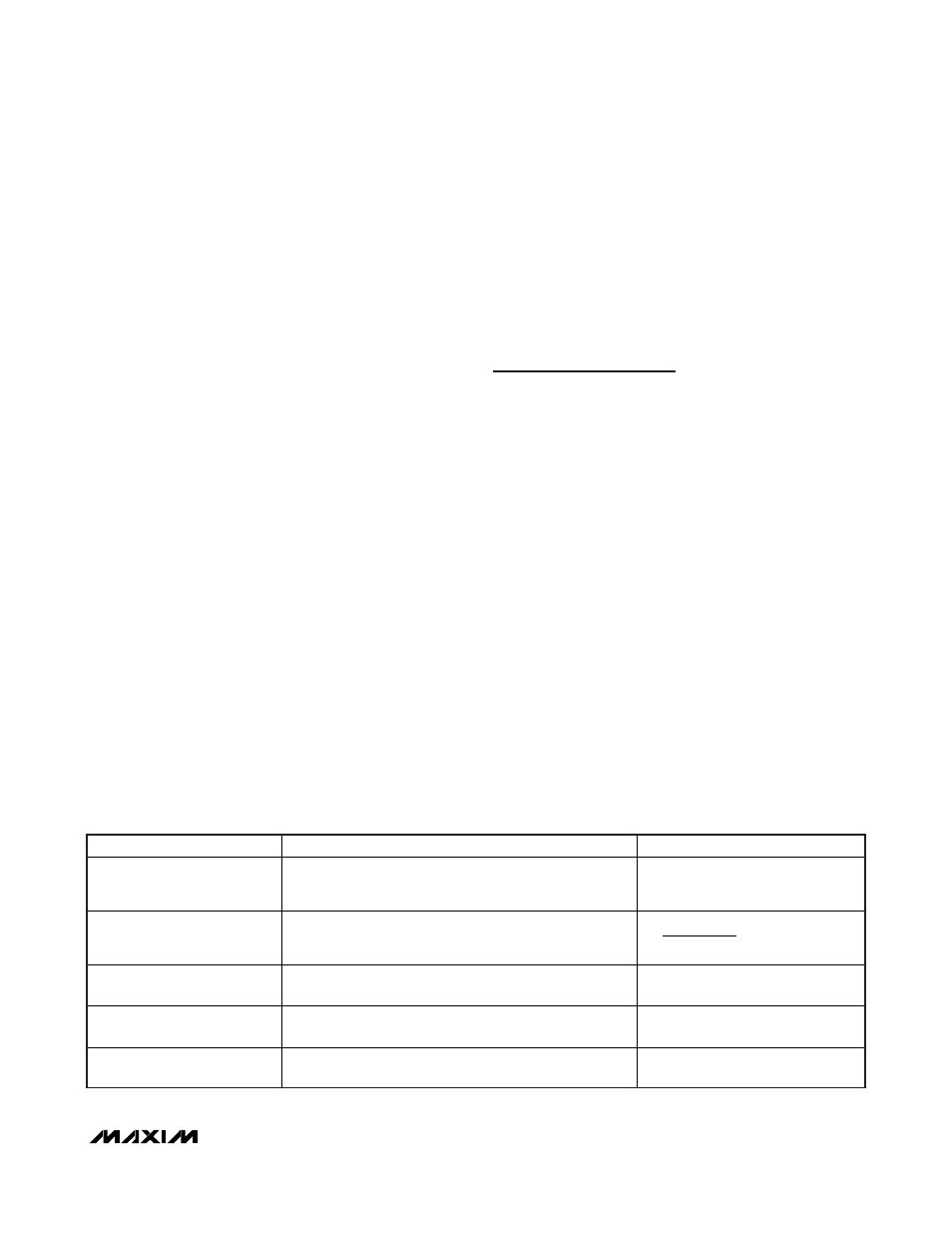

MODE

CONTROLLER STATE

DRIVER STATE

Shutdown (ON_ = High to Low)

Output UVP (Latched)

Voltage soft-shutdown initiated. Internal error-amplifier

target slowly ramped down to GND and output actively

discharged (automatically enters forced-PWM mode).

DL driven high and DH pulled low

after soft-shutdown completed

(output < 0.1V).

Output OVP (Latched)

Controller shuts down and EA target internally slewed

down. Controller remains off until ON_ toggled or V

CC

power cycled.

DL immediately driven high,

DH pulled low.

UVLO (V

CC

Falling-Edge)

Thermal Fault (Latched)

SMPS controller disabled (assuming ON_ pulled high),

10

output discharge active.

DL and DH pulled low.

UVLO (V

CC

Rising Edge)

SMPS controller disabled (assuming ON_ pulled high),

10

output discharge active.

DL driven high,

DH pulled low.

V

CC

Below POR

SMPS inactive, 10

output discharge active.

DL driven high,

DH pulled low.

Table 3. Fault Protection and Shutdown Operation Table