Tables, Application hints – Rainbow Electronics ADC12L038 User Manual

Page 25

Tables

(Continued)

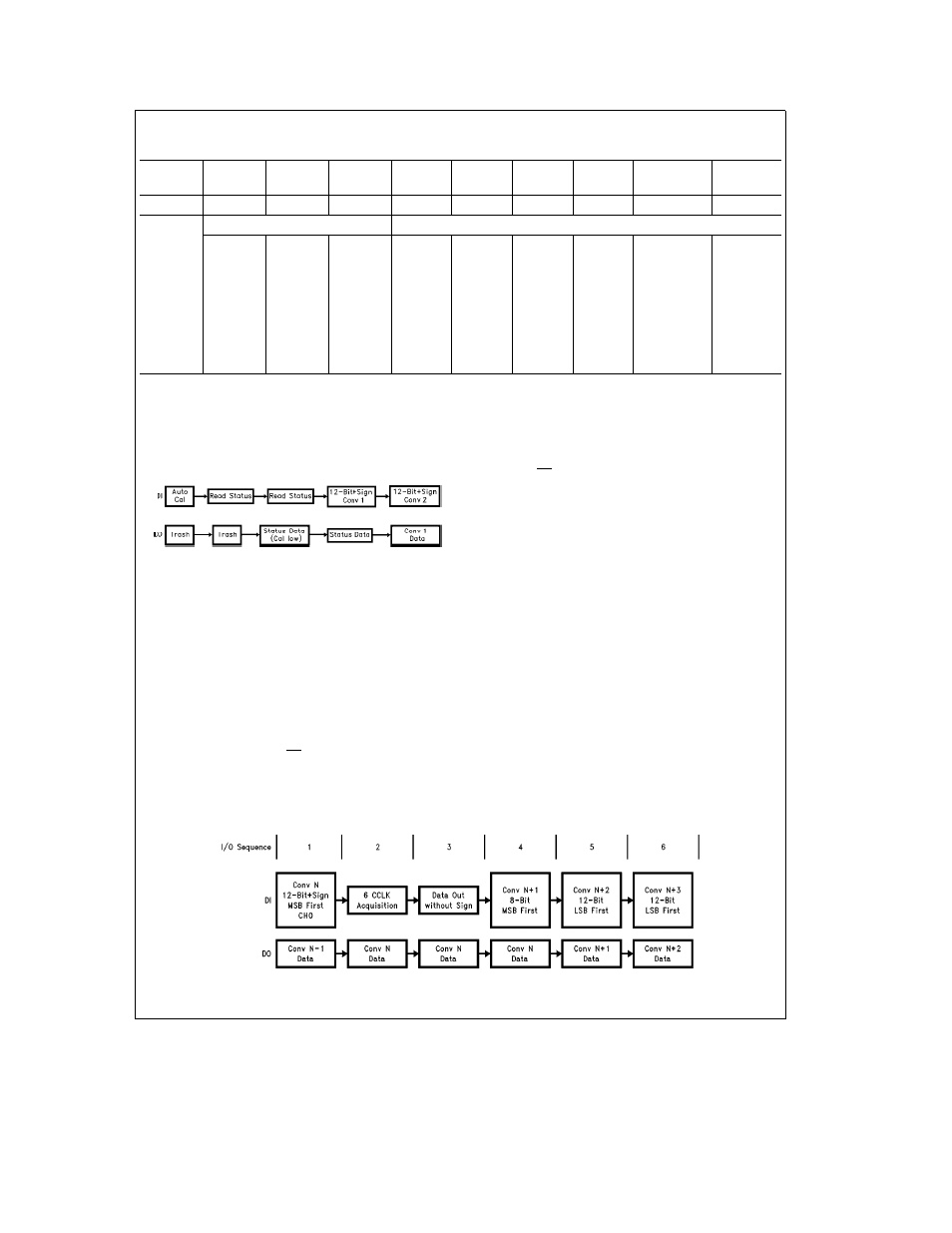

TABLE VII Status Register

Status Bit

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB8

Location

Status Bit

PU

PD

Cal

8 or 9

12 or 13

16 or 17

Sign

Justification

Test Mode

Device Status

DO Output Format Status

‘‘High’’

‘‘High’’

‘‘High’’

‘‘High’’

‘‘High’’

‘‘High’’

‘‘High’’

When ‘‘High’’

When

indicates

indicates

indicates

indicates

indicates

indicates

indicates

the

‘‘High’’ the

a Power

a Power

an Auto-

an 8 or 9

a 12 or

a 16 or

that the

conversion

device is in

Up

Down

Cal

bit format

13 bit

17 bit

sign bit is

result will be

test mode

Function

Sequence

Sequence

Sequence

format

format

included

output MSB

When

is in

is in

is in

When

first When

‘‘Low’’ the

progress

progress

progress

‘‘Low’’

‘‘Low’’ the

device is in

the sign

result will be

user mode

bit is not

output LSB

included

first

Application Hints

1 0 DIGITAL INTERFACE

1 1 Interface Concepts

The example in

Figure 5

shows a typical sequence of

events after the power is applied to the ADC12L030 2 4 8

TL H 11830 – 36

FIGURE 5 Typical Power Supply Power Up Sequence

The first instruction input to the A D via DI initiates Auto Cal

The data output on DO at that time is meaningless and is

completely random To determine whether the Auto Cal has

been completed a read status instruction is issued to the

A D Again the data output at that time has no significance

since the Auto Cal procedure modifies the data in the output

shift register To retrieve the status information an addition-

al read status instruction is issued to the A D At this time

the status data is available on DO If the Cal signal in the

status word is low Auto Cal has been completed Therefore

the next instruction issued can start a conversion The data

output at this time is again status information To keep noise

from corrupting the A D conversion the status can not be

read during a conversion If CS is strobed and is brought low

during a conversion that conversion is prematurely ended

EOC can be used to determine the end of a conversion or

the A D controller can keep track in software of when it

would be appropriate to communicate to the A D again

Once it has been determined that the A D has completed a

conversion another instruction can be transmitted to the

A D The data from this conversion can be accessed when

the next instruction is issued to the A D

Note when CS is low continuously it is important to transmit

the exact number of SCLK cycles as shown in the timing

diagrams Not doing so will desynchronize the serial com-

munication to the A D (see Section 1 3)

1 2 Changing Configuration

The configuration of the ADC12L030 2 4 8 on power up

defaults to 12-bit plus sign resolution 12- or 13-bit MSB

First 10 CCLK acquisition time user mode no Auto Cal no

Auto Zero and power up mode Changing the acquisition

time and turning the sign bit on and off requires an 8-bit

instruction to be issued to the ADC This instruction will not

start a conversion The instructions that select a multiplexer

address and format the output data do start a conversion

Figure 6

describes an example of changing the configura-

tion of the ADC12L030 2 4 8

During I O sequence 1 the instruction on DI configures the

ADC12L030 2 4 8 to do a conversion with 12-bit asign

resolution Notice that when the 6 CCLK Acquisition and

Data Out without Sign instructions are issued to the ADC

I O sequences 2 and 3 a new conversion is not started

The data output during these instructions is from conversion

N which was started during I O sequence 1 The Configura-

tion Modification timing diagram describes in detail the se-

quence of events necessary for a Data Out without Sign

Data Out with Sign or 6 10 18 34 CCLK Acquisition time

mode selection Table V describes the actual data neces-

TL H 11830 – 37

FIGURE 6 Changing the ADC’s Conversion Configuration

25