Electronics 500-P User Manual

Page 9

IM0053A Page 9 of 10

7.4.3.4 Catch and Weigh Test - Confirmation

It will be necessary to repeat the above procedure to confirm calibration

accuracy. Repeat the tests for all 10 segments. Additional adjustments to a single

segment may be made if it is necessary.

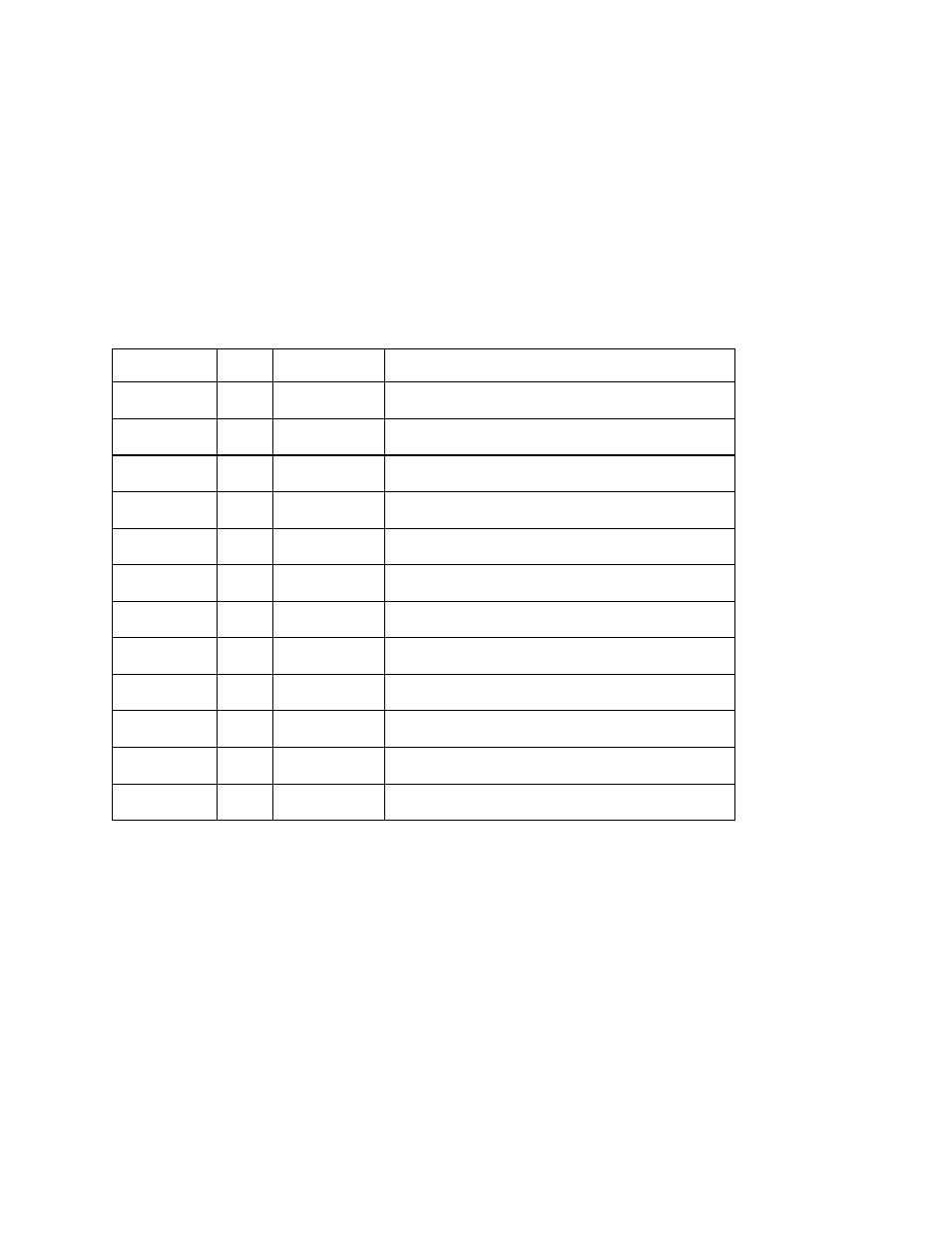

8. Description of 12-Position Pre-Amp Switch

The Pre-Amp selector switch is normally placed in the RUN position (fully CCW

rotation) and this sends the actual flow rate signal to the pre-amp display. To aide

calibration and compensation this switch is also used to send pre-set voltages into the

display.

POSITION

%

VOLTAGE

"FLOW" (assuming 0-1200 Lb/min range)

1 Run

-

Actual

Actual

2 Zero

0

0.00

ZERO

3

15

0.75

180

4

25

1.25

300

5

35

1.75

420

6

45

2.25

540

7

55

2.75

660

8

65

3.25

780

9

75

3.75

900

10

85

4.25

1020

11

95

4.75

1140

12

100 5.00

1200

9. Maintenance and Trouble Shooting

Occasional cleaning of the MagnaValve may be necessary to prevent build-up of

dust or other contaminants. If the valve is unable to achieve a requested shot flow rate

the controller will supply a 100% duty cycle control signal to the valve and the red LED

will be constantly on. The shot flow rate controller low alarm light will be on. These

symptoms indicate that the valve is starved and the system is either out of shot or a

blockage has occurred.

10. Spare Parts

The only spare parts recommended for the MagnaValve is a spare valve driver

module. The valve driver module is located on the back side of the Model 500

MagnaValve behind the finned heat radiator. A product label on the module will identify

its model number and setting of the correct 100% duty cycle dc coil current. Replacement