For types of lubricant, Maintenance, Notice – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-751-G2 User Manual

Page 68

9. Maintenance

68

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

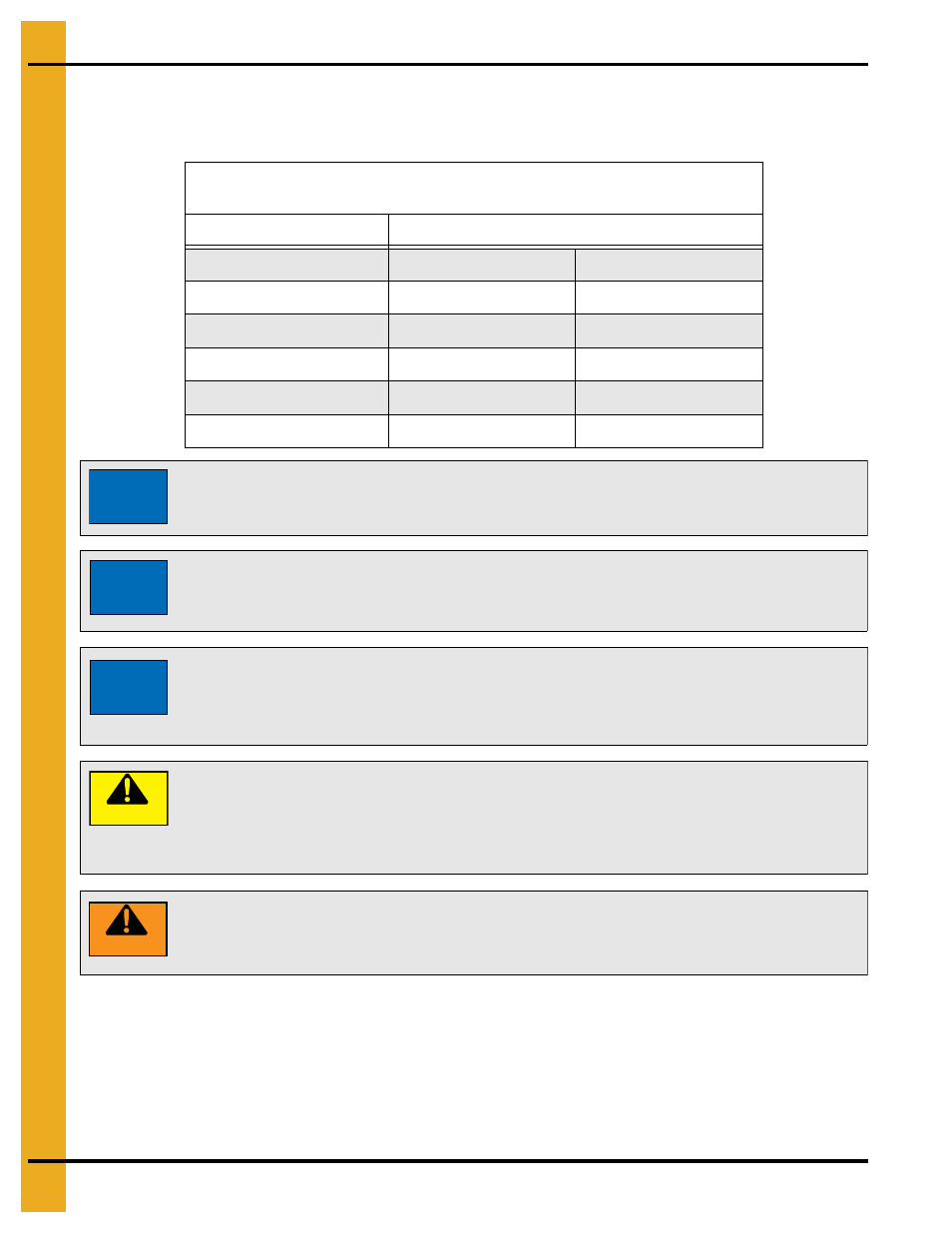

O. Type of Lubrication

The type of lubrication required, for each component, is listed in the following

NOTE: The pour point of the lubricant selected should be at least 10°F lower than the expected minimum

ambient starting temperature. Extreme pressure (EP) lubricants are not recommended for average

operating conditions.

Lubrication - Bearings, Casters and Misc. Equipment

Type of Lubricant

Equipment

Lubrication Specification

Tractor Drive Pillow Blocks Shell Oil Company

Alvania #2 (or equivalent)

End Flange Bearing

Shell Oil Company

Alvania #2 (or equivalent)

Nylon Flight Bearings

None Required

None Required

Head End Casters

Shell Oil Company

Alvania #2 (or equivalent)

Jack Casters

Shell Oil Company

Alvania #2 (or equivalent)

Jacks

Shell Oil Company

Alvania #2 (or equivalent)

Too much oil will cause overheating and too little will result in gear failure. Check

oil level regularly.

NOTICE

Extreme pressure (EP) lubricants are not recommended for average operating

conditions. Failure to observe these precautions could result in damage to or

destruction of the equipment.

NOTICE

Under Extreme operating conditions, such as rapid rise and fall of temperatures,

dust, dirt, chemical particles, chemical fumes or oil sump temperature above

200°F, the oil should be changed every 1 to 3 months, depending on severity

of conditions.

NOTICE

CAUTION

If the unit is used in the food or drug industry (including animal food) consult

the petroleum supplier for recommendations on lubricants which meet the

specifications of the FDA, USDA and/or other authoritative bodies having

jurisdiction. Standard lubricants are not suitable for these applications or

these industries.

WARNING

Oil, housings and other components can reach high temperatures during

operation and can cause severe burns. Use extreme care when removing

lubrication plugs and vents while servicing the unit.