Lubrication, Maintenance – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-751-G2 User Manual

Page 64

9. Maintenance

64

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Lubrication

A. Lubrication - Electric Motors

Electric motors supplied for use on Series II Sweeps are properly lubricated at the time of manufacture.

It is not necessary to lubricate them at the time of installation unless the motor has been in storage for

one year or longer. Some motors may be factory lubricated and sealed for the life of the bearings.

Overgreasing the bearings can cause premature failure of the motor. The amount of grease added must

be carefully controlled.

B. Procedure for Lubrication of Electric Motors

1. Stop motor. Disconnect and lock out of service.

2. Follow all safe bin entry procedures and wear all required personal protective equipment.

3. Remove contaminants from grease inlet area.

4. Remove filler and drain plugs.

5. Check filler and drain holes for blockage and clean as necessary.

6. Add proper type and amount of grease.

for amount of

lubricant. Too much grease or injecting grease too quickly can cause premature bearing

failure. Use approximately one minute to slowly inject the recommended amount of grease.

7. Wipe off excess grease and replace filler and drain plugs. Do not run motor without the grease

and drain plugs installed.

NOTE: It is very important to keep the grease clean. Mixing dissimilar grease is not recommended.

C. Type of Lubrication

A polyurea mineral oil NGLI grade 2 type grease is to be used for lubrication of the electric motors.

Grease meeting this specification include:

D. Frequency of Lubrication

Motors should be relubricated after storage of one year or more or at the beginning of each season.

The following

gives the amount of grease to be added.

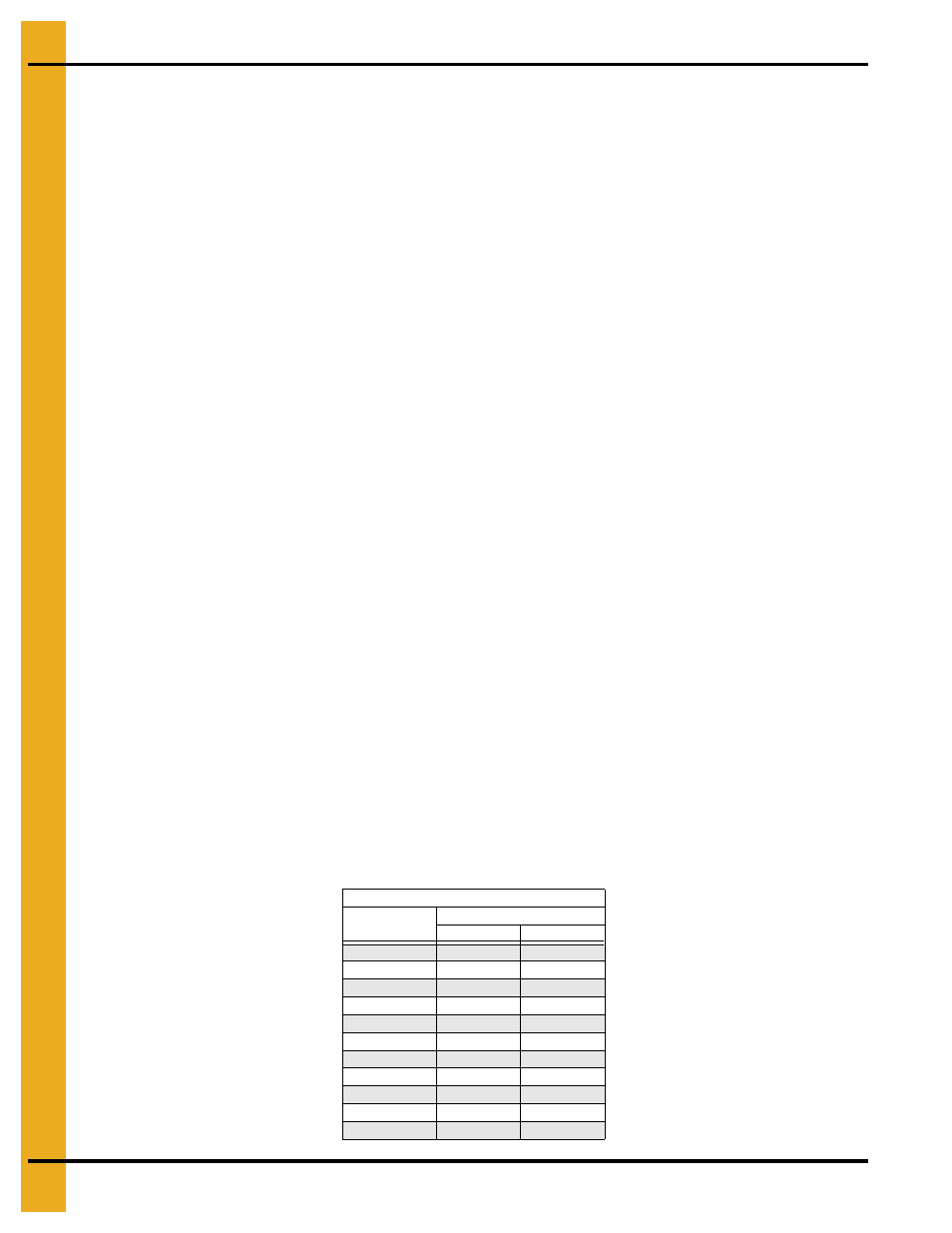

Lubrication - Electric Motors

Quantity of Grease per Frame Size

1. Chevron

SRI #2

2. Exxon-Mobile

Polyrex EM

3. Texaco

Polystar RB

For Baldor Brand Electric Motors

NEMA

Frame Size

Volume

Cu. in.

Fluid oz

56C

143TC

0.25

0.14

182TC

0.5

0.28

184TC

0.5

0.28

213T

0.75

0.42

215T

0.75

0.42

254T

1

0.55

256T

1

0.55

284T

1.25

0.69

286T

1.25

0.69

324T

1.5

0.83