Maintenance – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-751-G2 User Manual

Page 65

9. Maintenance

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

65

E. Lubrication - Reducers (Gearboxes)

Reducers supplied for use on Series II Sweeps are shipped without lubricant (dry). The proper lubricant

must be added at the time of installation. Over lubrication may cause premature failure of the reducer.

The amount of lubricant must be carefully controlled.

F. Procedure for Initial Filling of Reducers

1. Disconnect and lock motor out of service. Do not run gearbox without lubricant.

2. Follow all safe bin entry procedures and wear all required personal protective equipment.

3. Remove contaminants from inlet area.

4. Remove filler and oil level fill plugs.

5. Check filler holes for blockage and clean as necessary.

6. Clean the magnetic drain plug if one was supplied.

7. Add proper type of lubricant to fill level or until oil runs out of oil level fill hole.

See the Lubrication Chart on Page 66

for amounts and types of lubricant.

8. Wipe off excess lubricant and replace filler and oil level fill plugs.

NOTE: It is very important to keep the lubricant clean. Mixing dissimilar lubricants is not recommended.

G. Procedure for Changing of Lubricant

1. Stop motor. Disconnect and lock out of service.

2. Follow all safe bin entry procedures and wear all required personal protective equipment.

3. Remove contaminants from inlet and drain area.

4. Remove filler, oil level fill and drain plugs. Drain old lubricant from reducer.

5. Flush reducer with a nonflammable solvent such as lubriplate pure flush or whitmore’s

flushing oil.

6. Clean the magnetic drain plug if installed.

7. Carefully replace drain plug.

8. Add proper type of lubricant to fill level or until oil runs out of oil level fill hole.

See the Lubrication Chart on Page 66

for amounts and types of lubricant.

9. Wipe off excess lubricant and replace filler and oil level fill plugs.

NOTE: It is very important to keep the lubricant clean. Mixing dissimilar lubricants is not recommended.

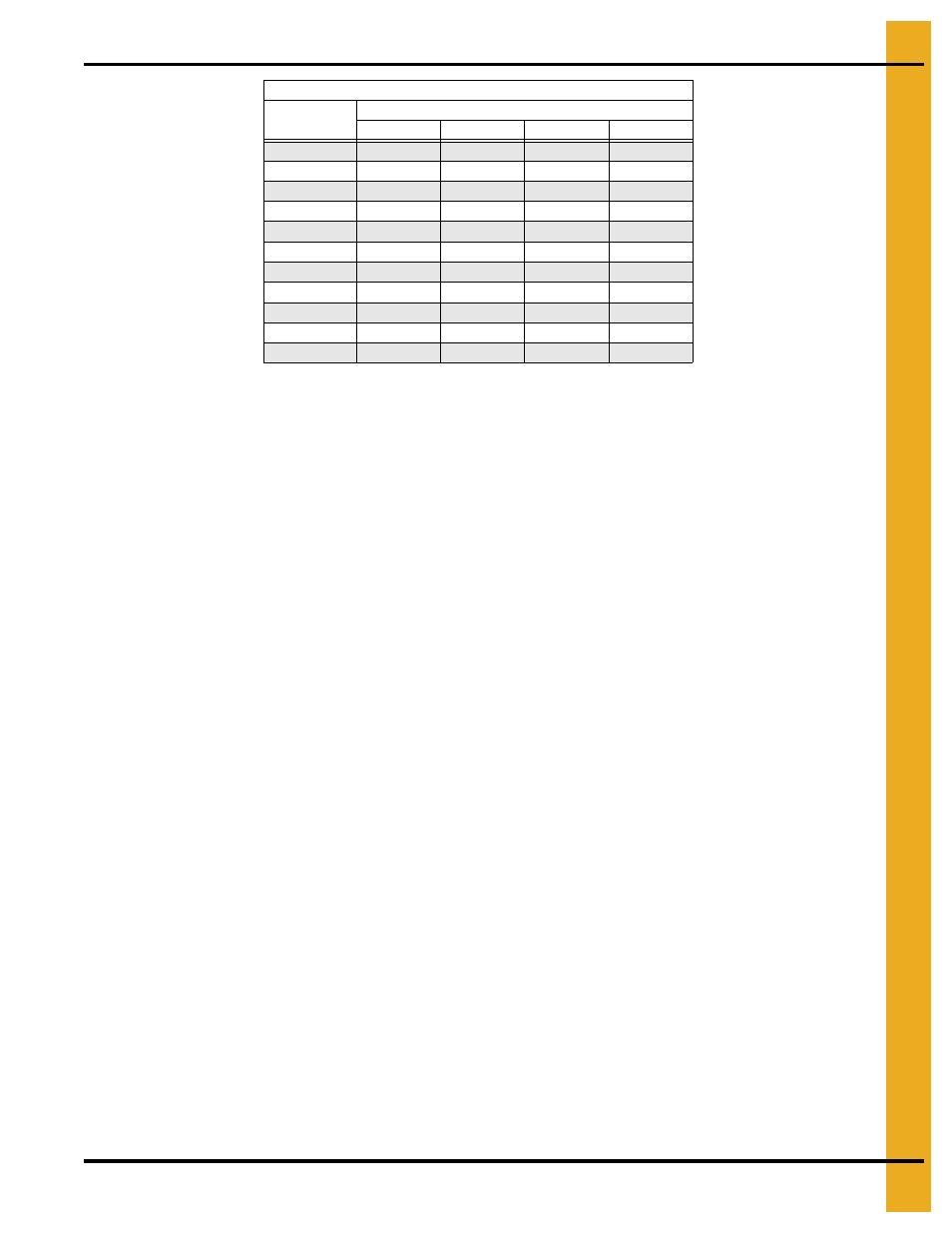

For Marathon Brand Electric Motors

NEMA

Frame Size

Volume

Cu. in.

Ounce

Gram

Teaspoon

56C

143TC

0.6

0.3

8.4

2

182TC

0.6

0.3

8.4

2

184TC

0.6

0.3

8.4

2

213T

0.6

0.3

8.4

2

215T

0.6

0.3

8.4

2

254T

1.2

0.61

17.4

3.9

256T

1.2

0.61

17.4

3.9

284T

1.2

0.61

17.4

3.9

286T

1.2

0.61

17.4

3.9

324T

1.5

0.81

23.1

5.2