Taper-lock bushings, General product information – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-751-G2 User Manual

Page 20

4. General Product Information

20

PNEG-751-G2 12" Series II Sweep 131' and 135' Diameter

Taper-Lock Bushings

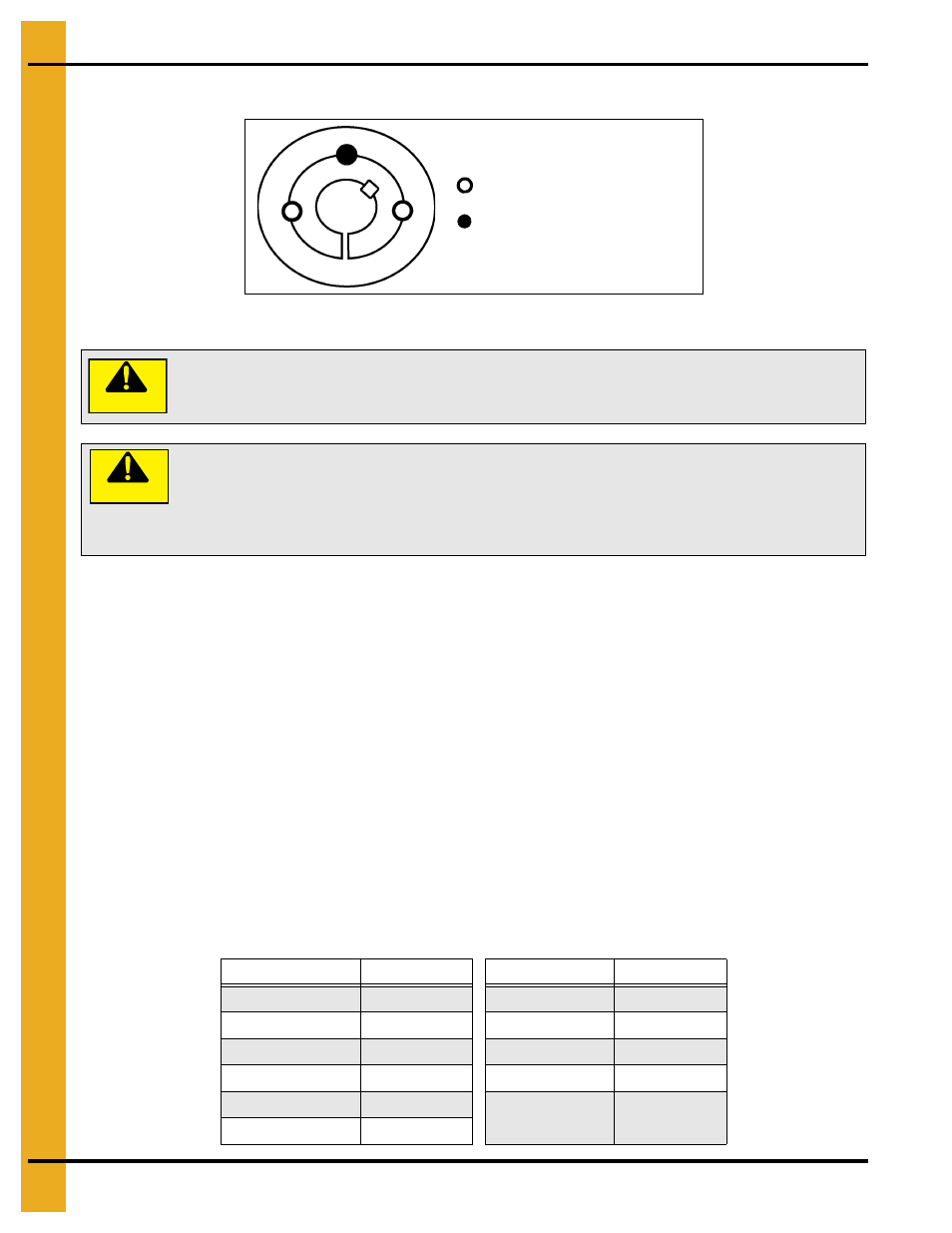

Figure 4A Number 1008 to 3030 Bushing

To Install

1. Clean shaft, bore and outside of bushing and hub bore of all oil, paint and dirt. File away burrs.

2. Insert bushing in hub. Match the hole pattern, not threaded holes (each complete hole will be

threaded on one side only).

3. Lightly oil set screws and thread into the half-threaded holes indicated as in

4. Position the assembly onto the shaft allowing for the small axial movement which will occur during

the tightening procedure.

5. Alternately torque set screws to recommended torque setting listed in the

6. To increase the gripping force, hammer the face of the bushing using a drift or sleeve. (Do not hit the

bushing directly with the hammer.)

7. Re-torque the screws after hammering.

8. Re-check the screw torques after the initial run-in and periodically thereafter. Repeat

,

and

if loose.

Recommended Installation Wrench Torque

Bushing #

lbs.-in

Bushing #

lbs.-in

1008, 1108

55

3535

1000

1210, 1215, 1310

175

4040

1700

1610, 1615

175

4545

2450

2012

280

5050

3100

2517, 2525

430

6050, 7060, 8065

7820

3020, 3030

800

Insert set screws to install

Insert set screw to remove

CAUTION

Wedging forces in the bushing saw slot, such as that exerted by a narrow edged

regular screw driver, may damage or break the bushing. This damage would not

be covered under the GSI warranty.

Do not lubricate the bushing taper, bushing bore, hub taper or the shaft. Doing so

could result in breakage of the product.

Do not use worn hex key wrenches. Doing so may result in a loose assembly or

may damage the screws.

CAUTION