See table, Electrical power supply, Transformers and wiring voltage drop – Grain Systems PNEG-1458 User Manual

Page 20: Power supply disconnect, Machine to earth grounding, Dryer installation

4. Dryer Installation

20

PNEG-1458 T-Series Tower Dryer

Fuel System Recommendations

Electrical Power Supply

An adequate power supply and proper wiring are important factors for maximum performance and long

life of the dryer. Electrical service must be adequate enough to prevent low voltage damage to motors and

control circuits.

Transformers and Wiring Voltage Drop

Advise the service representative of the local power supplier that an additional load will be placed on the

line. Check on KVA rating of transformers, considering total horsepower load. The power supply wiring,

main switch equipment and transformers must provide adequate motor starting and operating voltage.

Voltage drop during motor starting should not exceed 14% of normal voltage and after motor is running at

full speed it should be within 8% of normal voltage.

Power Supply Disconnect

All dryers are equipped with a power disconnect switch in the power box to permit total power shut down

before opening the power box door, as required for inspection and service. The power disconnect switch

is located on the power box door for quick shut down.

Machine to Earth Grounding

It is very important that a machine to earth ground rod be installed at the dryer. Place the ground rod that

comes standard, within eight feet (8') of the dryer and attach it to the dryer control panel with at least a #6

solid, bare, copper ground wire and the clamp provided. The grounding rod located at the power pole will

not provide adequate grounding for the dryer. The proper grounding will provide additional safety

in case of any short and will ensure long life of all circuit boards, SCR drive and the ignition system.

The ground rod must be in accordance with local requirements.

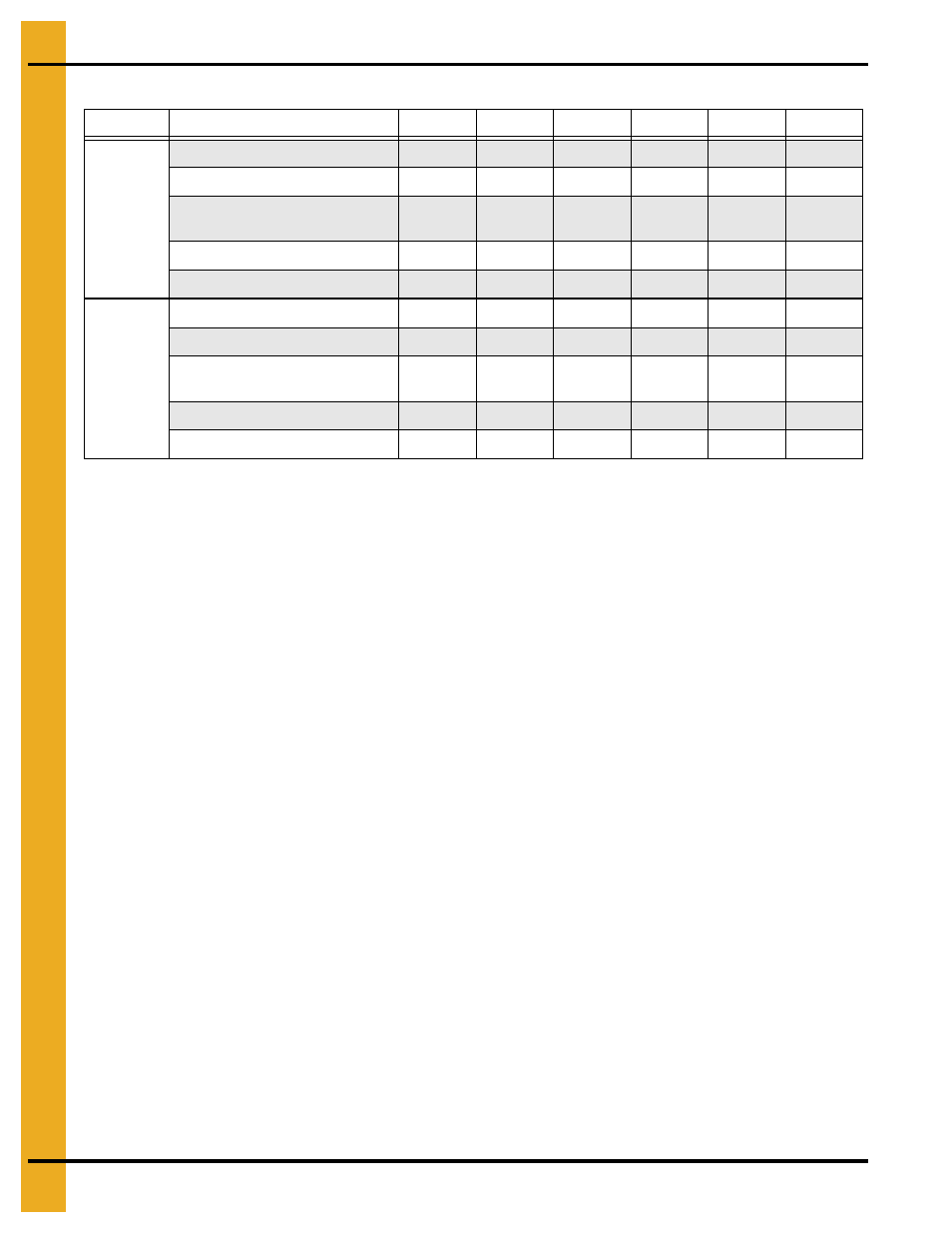

1050

1260

1575

1875

20100

24100

Liquid

Propane

Burner Capacity (Btu/Hr)¹

11100000

11100000

16654000

17669000

21298000

23393000

Maximum Fuel Usage (Gal/Hr)

121

121

182

193

233

255

Recommended Liquid

Line Size (>100')

3/4"

3/4"

3/4"

1"

1"

1"

Fuel Train Orifice Size (inch)

0.625"

0.625"

0.7187"

0.787"

0.781"

0.781"

Pressure Regulator Setting (PSI)

9

9

9

9

9

9

Natural

Gas

Burner Capacity (Btu/Hr)

11100000

11100000

16654000

17669000

21298000

23393000

Maximum Fuel Usage (Cu Ft/Hr)

11100

11100

16654

17669

21298

23393

Recommended Liquid

Line Size (>100')

2"

2"

2-1/2"

2-1/2" 2-1/2"

2-1/2"

Fuel Train Office Size (inch)

0.7187"

0.7187"

0.8125"

0.875"

1.000"

1.000"

Regulated

Supply

Pressure

(PSI)

10

10 10 10 10 10

¹Burner capacity for fuel line sizing. Actual average fuel usage is typically 50%-60% of the burner capacity.