Chapter 4: assembling sidewall sheets – Grain Systems Tanks PNEG-4105A User Manual

Page 41

Chapter 4: Assembling Sidewall Sheets

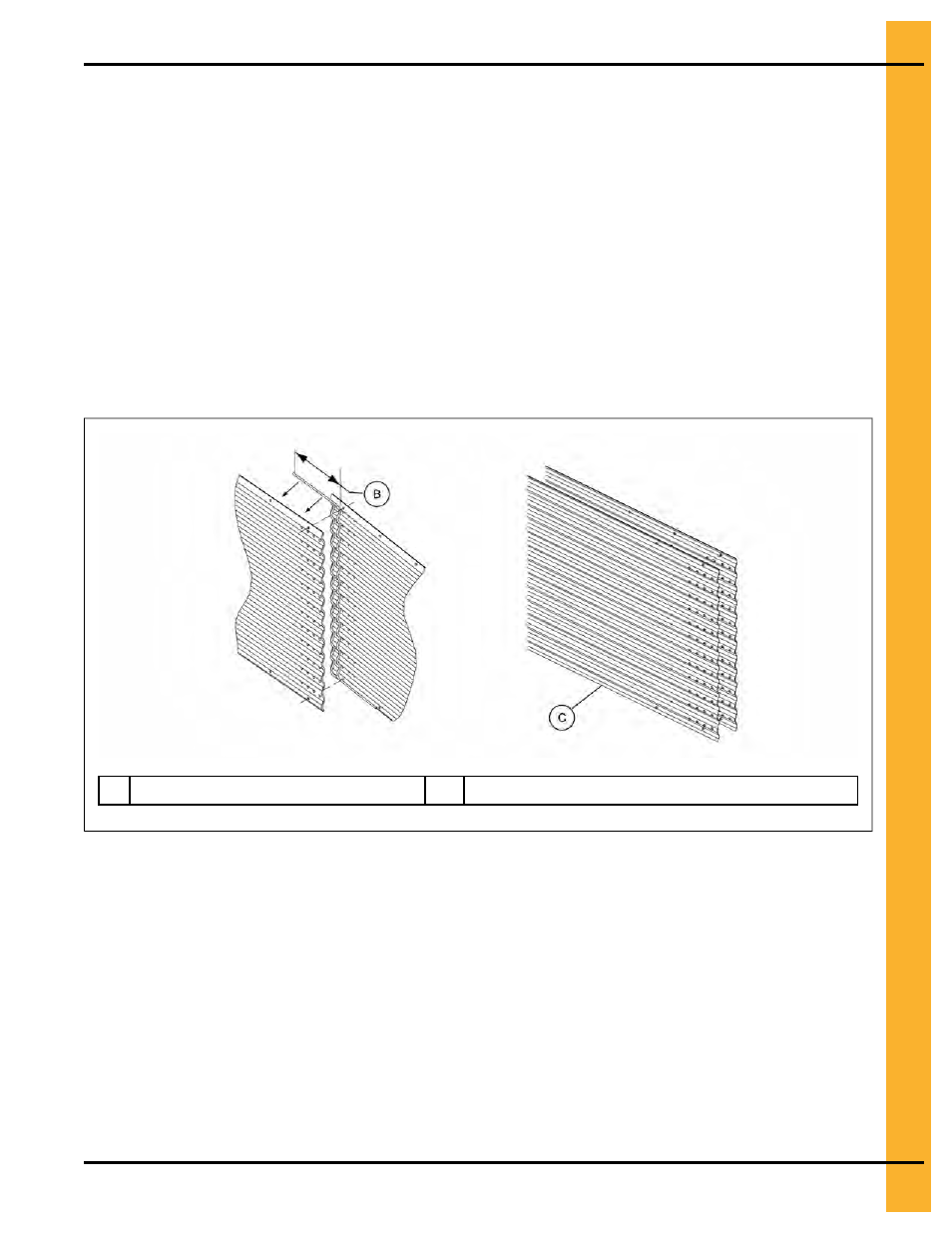

• When assembling two assembled laminated sheets to each other, apply a strip of caulk (A) near the

outside edge of the outer sheet, between the outer two (2) rows of bolts and outside the last row of

bolts.

• Place a strip of caulk (B) 12 in. (30.4 cm) long to each the horizontal seams.

NOTE: Before bolting the next ring into place, apply a strip of caulk 12 in. (30.4 cm) long on the front

of the under lapped sheet at each joint.

• Also, a 12 in. (30.4 cm) strip of caulk is to be placed along the lower horizontal edge of the lapping

sheet at the vertical seam. This will fill the space that occurs between the holes caused by the over-

lapping sheets.

When assembling two sheets to make a laminated sheet assembly (C), apply a row of caulk all around the

vertical seam.

Use the supplied tube caulk to fill the larger gaps that occur with heavier gauges and laminated sheets.

Figure 4-7 Caulking detail for assembled laminated sidewall sheets

B

12 in. (30.4 cm) horizontal strip of caulk

C

Laminated sheet detail (caulk not shown)

Pneg-4105A 105 Ft Diameter 40-Series Bin

41