Assembling a double a-frame, Chapter 7: roof assembly – Grain Systems Tanks PNEG-4105A User Manual

Page 105

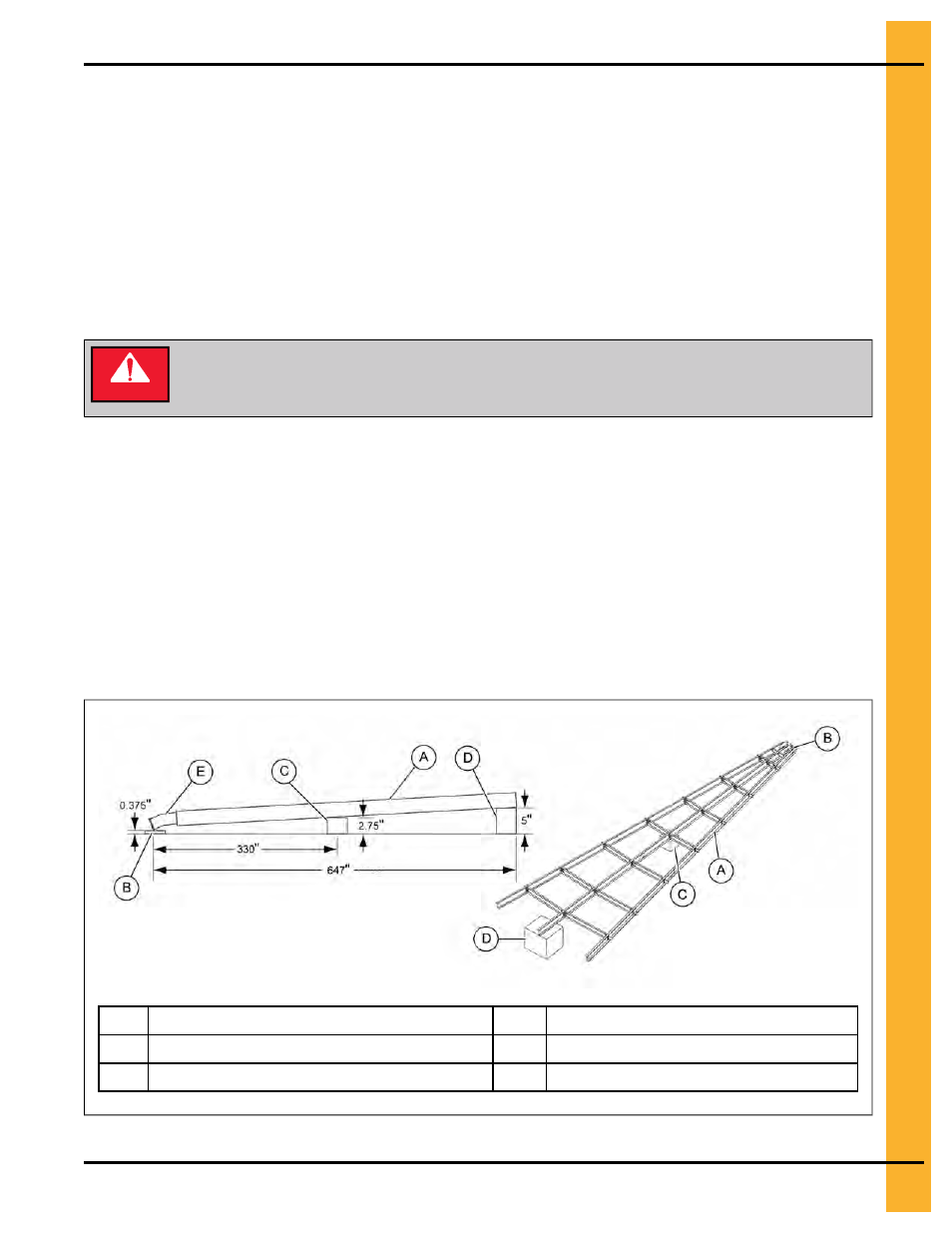

Assembling a Double A-Frame

To achieve the required spacing between each A-frame, a double A-frame will need to be assembled prior

to installing and lift into place as one assembly.

Before You Begin

The double A-frame assembly will consist of three assembled roof rafters, purlin clips, and purlins. There

are also two different purlin clips, a left purlin clip (B) and a right purlin clip (C). The left purlin clip has six

holes, compared to the right, which has seven holes along the purlin clip mating surface.

NOTE: The seventh hole located in the center of the right purlin clip (C) is for identification purposes only.

No hardware is used in the location.

What You Should Know

DANGER

The completed assembly is extremely heavy, and all lifting should be performed by a

certified crane operator with prior bin construction experience. Never lift during

windy conditions.

When fully assembled the double A-frame becomes very heavy.

1. Place a roof rafter (A) parallel to an assembled A-frame (I).

2. Install left and right purlin clips (B and C) at locations shown, and secure the left and right purlin clips

to the roof rafter (A) using flange bolts (D) and nuts (E).Tighten to the recommended torque, see

Torque Specifications, page 25

specifications.

3. Install a purlin (H) at each location shown, and install flange bolts (F) and nuts (G).

IMPORTANT: The center rafter in the double A-frame will need to be assembled on blocks raising it

above the other rafters. This is necessary to adjust for the difference in rafter eleva-

tions due to the conical shape of the roof.

Figure 7-21 Double A-Frame rafter assembly with blocks

A

Rafter

D

Block at the bottom (below the rafter)

B

Block at the top (below the roof rafter clip)

E

Roof rafter clip

C

Block at the middle (below the rafter)

Pneg-4105A 105 Ft Diameter 40-Series Bin

105