Td-vip-01 data sheet selection – Grain Systems PNEG-1798 User Manual

Page 30

8. TD-VIP-01 Data Sheet Selection

30

PNEG-1798 Tower and T-Series Dryers Vaporizer

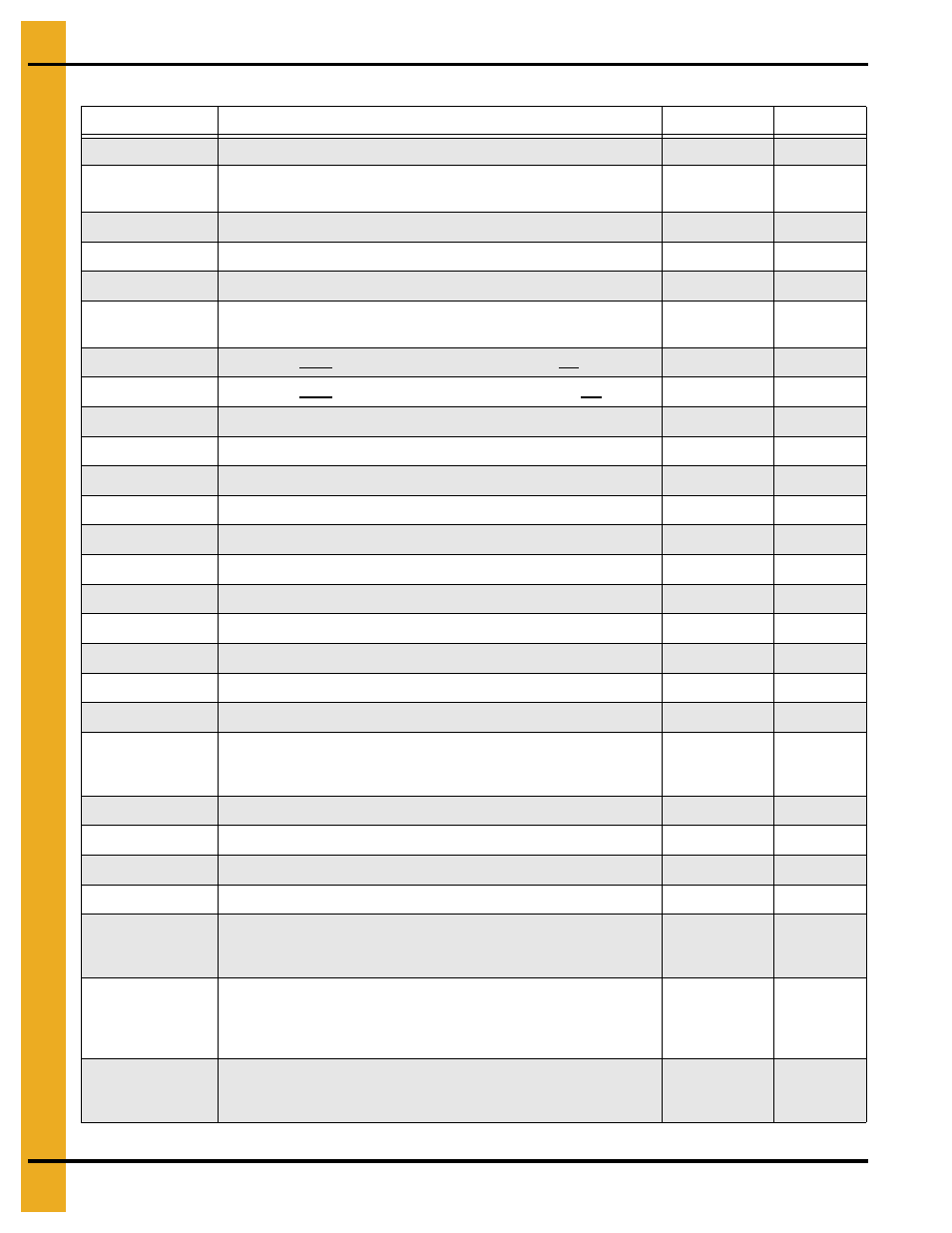

Vaporizer Pressure Leak Test Data

Step #

Information

Recorded Data

Initials/Date

Bushing installed to accept the 300 PSIG test gauge.

Regulator connected to nitrogen cylinder and handle or knob

turned fully CCW.

High pressure hose connected to the regulator.

Hose end connected to the 3/4" manual isolation valve input.

Hose ends tightened at regulator and manual valve.

Power cord available and ready to connect to the 3/4" ASCO

solenoid valve wires.

Power cord black wire connected to one of the ASCO red wires.

Power cord white wire connected to the remaining ASCO red wire.

Power cord green wire connected to the ASCO green wire.

Power cord 3 prong male end plugged in a live 120V receptacle.

Audible click or popping sound heard at 3/4" ASCO solenoid.

Regulator high pressure gauge pressure reading.

PSIG

3/4" Manual isolation valve ‘CLOSED’.

Regulator low pressure gauge pressure reading.

PSIG

No leaks between nitrogen cylinder and input of 3/4" manual valve.

Test gauge reading with 3/4" manual valve ‘CLOSED’.

PSIG

Test gauge reading with 3/4" manual valve ‘OPEN’.

PSIG

Number of leaks initially found before repairs.

Leaks

Leaks of

repaired (If applicable).

1. Regulator adjusted to test pressure.

2. 0 Minute test time.

1. ______ PSIG

2. ______ Time

3/4" Manual isolation valve ‘CLOSED’.

Nitrogen cylinder supply valve ‘CLOSED’.

Regulator vented and no pressure indicated on regulator gauges.

Test gauge pressure reading during this step.

PSIG

1. Test pressure of

.

2. 3 Minute test time after time of

.

1. ______ PSIG

2. ______ Time

‘As found’

beginning of

3 minutes

1. Regulator adjusted to test pressure.

2. 0 Minute test time.

1. ______ PSIG

2. ______ Time

‘As left’ end of

3 minutes

1. Regulator adjusted to test pressure.

2. 0 Minute test time.

1. ______ PSIG

2. ______ Time