For va – Grain Systems PNEG-1798 User Manual

Page 23

7. Procedure

PNEG-1798 Tower and T-Series Dryers Vaporizer

23

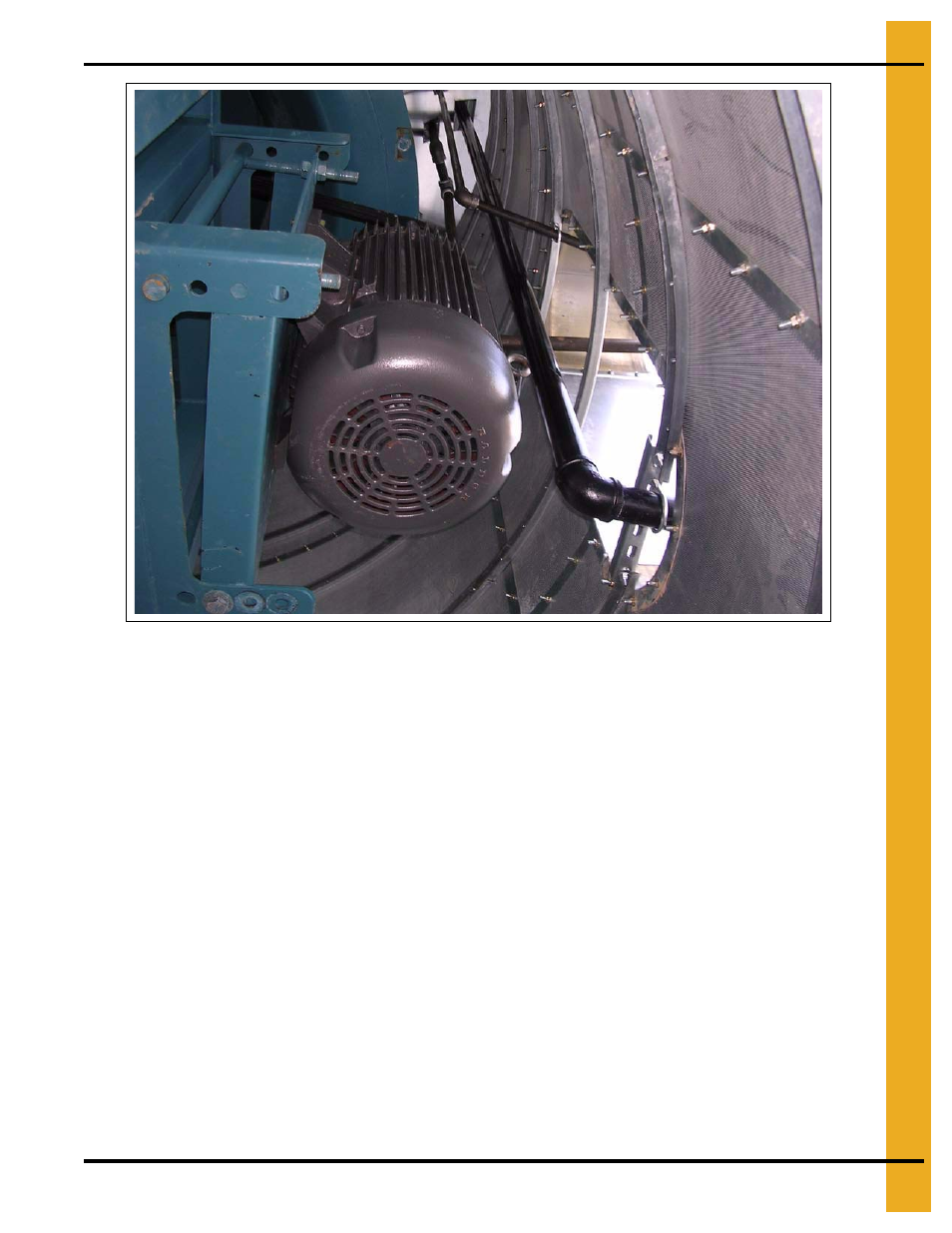

Figure 7Q Piping Exiting the Window using U-Bolts and Support Brackets

7.3.7. Vaporizer piping (3/4" and 1-1/4") continues downward through the piping window opening and

then vertically and in parallel with the 2" burner supply line toward the gas train.

7.3.8. Continue piping (3/4" and 1-1/4") downward to the gas train. Anchor the vertical run piping in at

least two (2) locations on the outside of the dryer. Uni-strut and clamps are commonly used for this.

7.3.9. Connect the 3/4" vaporizer line to the gas train liquid supply line. This will allow this section of the

gas train supply piping and associated components to be pressure tested in

.

7.3.10. Install a 2" to 1/4" reducing bushing at the end of the 2" to 1-1/4" bell reducer for the connection

of a test gauge. Some test gauges may have a 3/8" MNPT fitting, if so reduce down to allow a for

the test gauge connection size.

7.3.11. Install the 0-300 PSIG test gauge at the reducer bushing fitting of the preceding step. Verify this

gauge has a 0 PSIG reading.

7.3.12. Proceed to vaporizer high pressure leak testing