Toner Cable G2 2 Piece Connector Series User Manual

G2 2-piece connector series, Corning gilbert g2 2-piece connector series

Telephone:

Nationwide:

Fax:

E-mail:

Internet:

07/02

Corning Gilbert G2 2-Piece Connector Series

215-675-2053

800-523-5947

215-675-7543

http://www.tonercable.com

969 Horsham Road

Horsham, Pennsylvania 19044 USA

G2 2-Piece Connector Series

Corning Gilbert Introduces the next

generation in 2-piece connectors with

patented design features providing

clear performance advantages over

traditional 2-piece connectors.

Only the G2 Series gives installers a

full view of the cable’s center conduc-

tor insertion into the connector seizing

mechanism, eliminating traditional blind

entry. A unique center conductor seiz-

ing system prevents actuator lockup

and preserves connector reusability.

With the patented support sleeve locat-

ed in the back nut of the connector,

cable “pull back” is minimized. This

eliminates cable kinking typically asso-

ciated with 2-piece connector installa-

tion.

An industry first tri-start threading sys-

tem (patent pending) minimizes the

required back nut rotations when tight-

ening the connector.

MATERIALS AND CONSTRUCTION

BODY COMPONENTS:

ASTM 6262 aluminum alloy with gold chro-

mate conversion coating for excellent cor-

rosion resistance and dry lubricant to pre-

vent thread galling

RF COMPONENTS:

Contact pins and support sleeves are

brass with bright acid tin plating providing

excellent RF conductivity.

O-RINGS:

Ultraviolet and ozone resistant EPDM for

maximum durability.

SPECIFICATIONS

Connectors are designed to meet SCTE interface

specifications

BANDWIDTH:

5 MHz to 1 GHz

OPERATING RANGE:

-40°F TO +140°F

NOMINAL IMPEDANCE:

75 ohms

SHIELDING EFFECTIVENESS: >130 dB

RETURN LOSS:

30 dB min to 1 GHz

INSERTION LOSS:

<0.12 dB (pin types)

CABLE RETENTION: Meets or exceeds the cable

manufacturers’ maximum pulling tension specifications

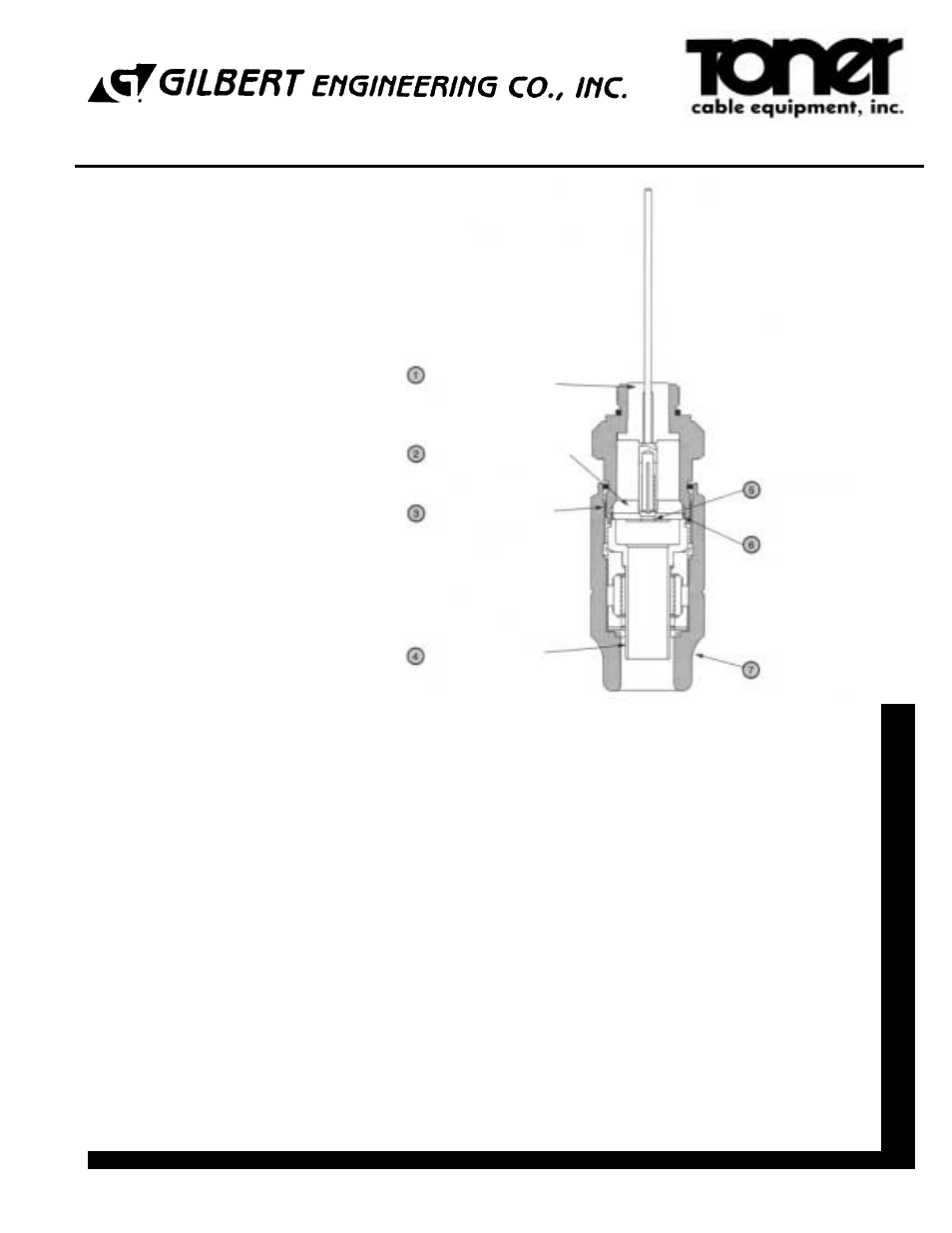

Flush insulator prevents

moisture from collecting

or migrating along the pin

Actuator closing mechanism

preserves reusability

Tri-start threading system

reduces installation time

Support sleeve located

in back nut reduces "pull

back" during installation

Back nut radius allows

smooth transition of

heat shrink tubing

No "blind entry" of

center conductor into

seizing mechanism

Non-rotational design

for installation and

disassembly