Front linkage, Built to perform the toughest tasks – Milton CAT 390D L User Manual

Page 9

9

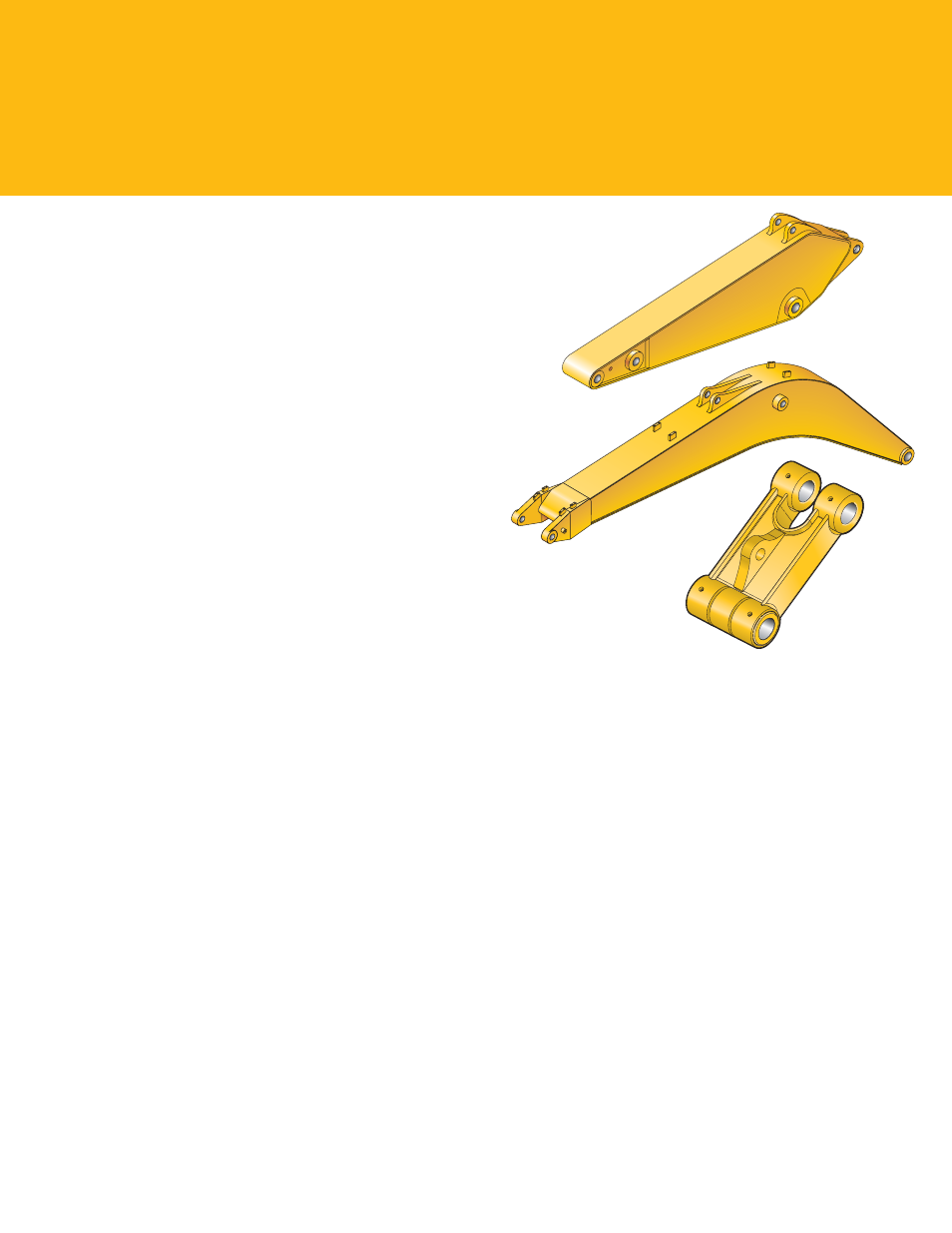

Front Linkage

Built to perform the toughest tasks

Front Linkage

Cat

®

Excavator booms and sticks are built for performance

and long service life.

•

Castings and forgings are used at high stress areas

such as the boom nose, boom foot, boom cylinder

and stick foot.

•

All booms and sticks are stress-relieved for optimal

life and durability while minimizing weight for

improved performance.

•

All booms and sticks are ultrasonic inspected

to ensure reliability.

Bucket Linkage

Two bucket linkages are available for the 390D L. Both are

available with or without a lifting eye.

Boom Construction

390D L booms feature a large cross section to improve

strength, reduce weight and maximize payload. Baffl e plates

reinforce the boom interior for higher rigidity.

Stick Construction

Sticks are made of high-tensile strength steel in a box-section

design, making them strong and light. All sticks are reinforced

with a thick baffl e plate for added rigidity. The connection

between stick and boom is made of forged steel, and a thick

steel plate is used at the bucket connecting location for increased

strength and rigidity at load-bearing points. An additional

wear plate is added to the bottom plate to protect against

damage. There are two reach sticks, three general purpose

sticks and two mass sticks available to meet your needs.

Linkage Pins

All front linkage pins have thick chrome plating, giving them

high wear resistance. Each pin diameter is made to distribute

the shear and bending loads associated with the stick and

to help ensure long pin, boom and stick life.