Milton CAT 988H User Manual

Page 5

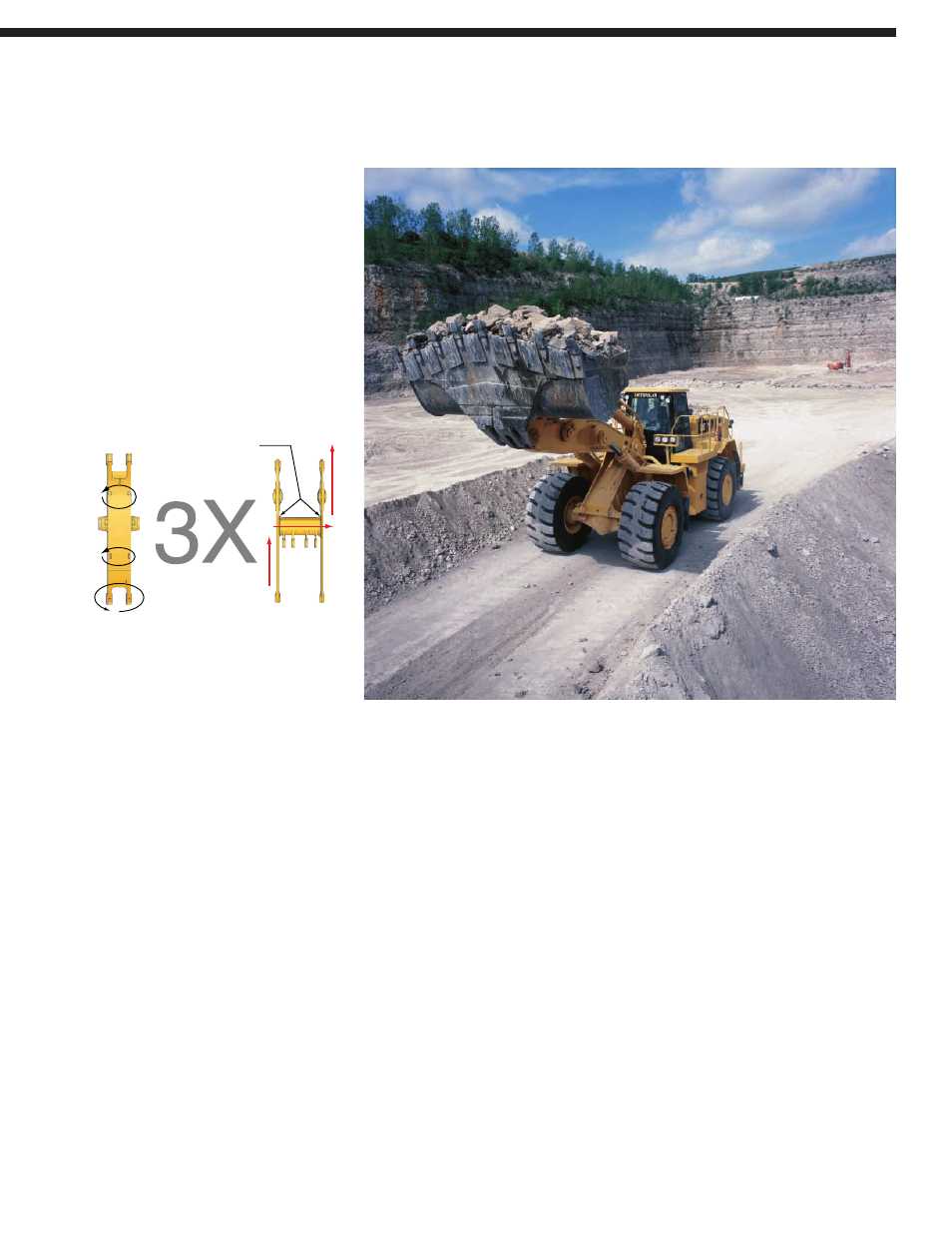

3 Upper and Lower Hitch Pins. Pivot on

double-tapered roller bearings. The hitch

plates are shaped to direct stress away

from the end of the weld, resulting in

a smoother transition of stress loads

into the frame.

4 Spread-Hitch Design. Increases the

spread 26 percent to help square-up the

frame and provide increased clearance

for access to the hitch and hydraulic lines.

5 Steering Cylinder Mounts. Are located

on the axle pads to provide efficient

transfer of steering loads to the axle.

6 Fabricated Box Boom. Replaces the

traditional steel plate lift arms found

on wheel loaders. This design features

forked ends for easier service, faster

assembly and increased reliability.

Castings in high stress areas smooth

the transition of stress distribution for

excellent service life. The boom and dual

bucket links work together for increased

breakout force, better torsional resistance

and higher lift capacity.

Fabricated Boom Box-Section Design.

Has more torsional stiffness than a Z-bar

design. With the parallel lift arm design,

corner loading the bucket sends stresses

up the lift arm, through the cross tube

welding and up the other lift arm.

The box-section design spreads stresses

over the full length and perimeter of the

boom, allowing stress transfer through

parent material. This resists twisting

and prevents stress paths that can

lead to cracking.

Weld Joint

Load Path

Load Path

(Full Length)

5