VEGA VEGAFLEX 82 Profibus PA User Manual

Page 19

19

4 Mounting

VEGAFLEX 82 • Profibus PA

44220-EN-130910

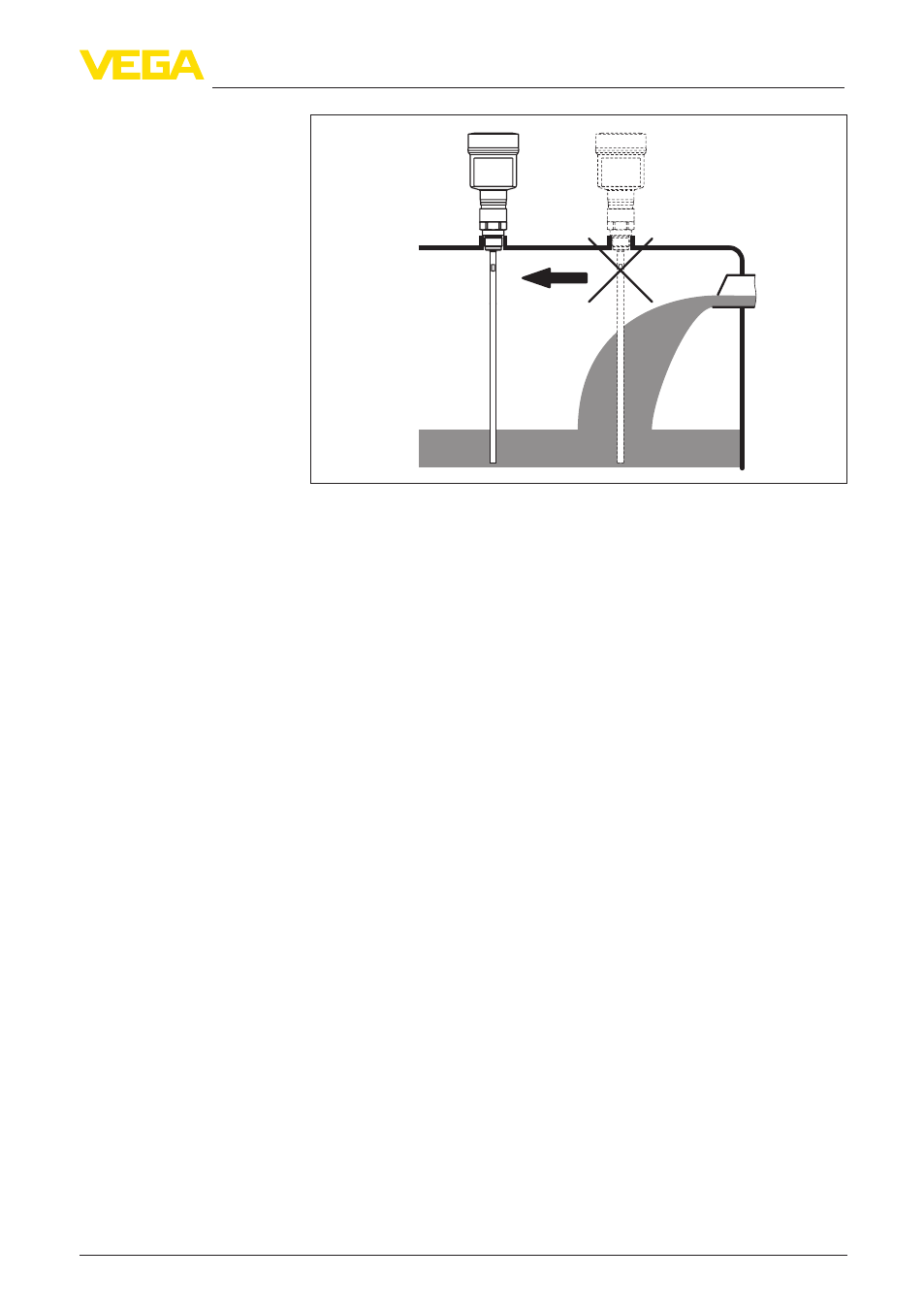

Fig. 10: Mounting of the sensor with inflowing medium

The reference plane for the measuring range of the sensors is the

sealing surface of the thread or flange.

Keep in mind that a min. distance must be maintained below the refer-

ence plane and possibly also at the end of the probe - measurement

in these areas is not possible (dead band). The length of the cable

can be used all the way to the end only when measuring conductive

products. These blocking distances for different mediums are listed

in chapter "Technical data". Keep in mind for the adjustment that the

default setting for the measuring range refers to water.

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical

data" or on the type label of the sensor.

If there is a risk of the cable probe touching the vessel wall during

operation due to product movements or agitators, etc., the measuring

probe should be securely fixed.

In the gravity weight there is an internal thread (M12), e.g. for an eye-

bolt (optional) - (article no. 2.27423).

Make sure that the probe cable is not completely taut. Avoid tensile

loads on the cable.

Avoid undefined vessel connections, i.e. the connection must be

either grounded reliably or isolated reliably. Any undefined change of

this requirement can lead to measurement errors.

Measuring range

Pressure

Fasten