6 measurement setup density and interface – VEGA VEGADIF 65 Foundation Fieldbus User Manual

Page 27

27

4 Mounting

VEGADIF 65 • Foundation Fieldbus

36130-EN-130417

+

–

min.

max.

1

2

3

4

5

+

–

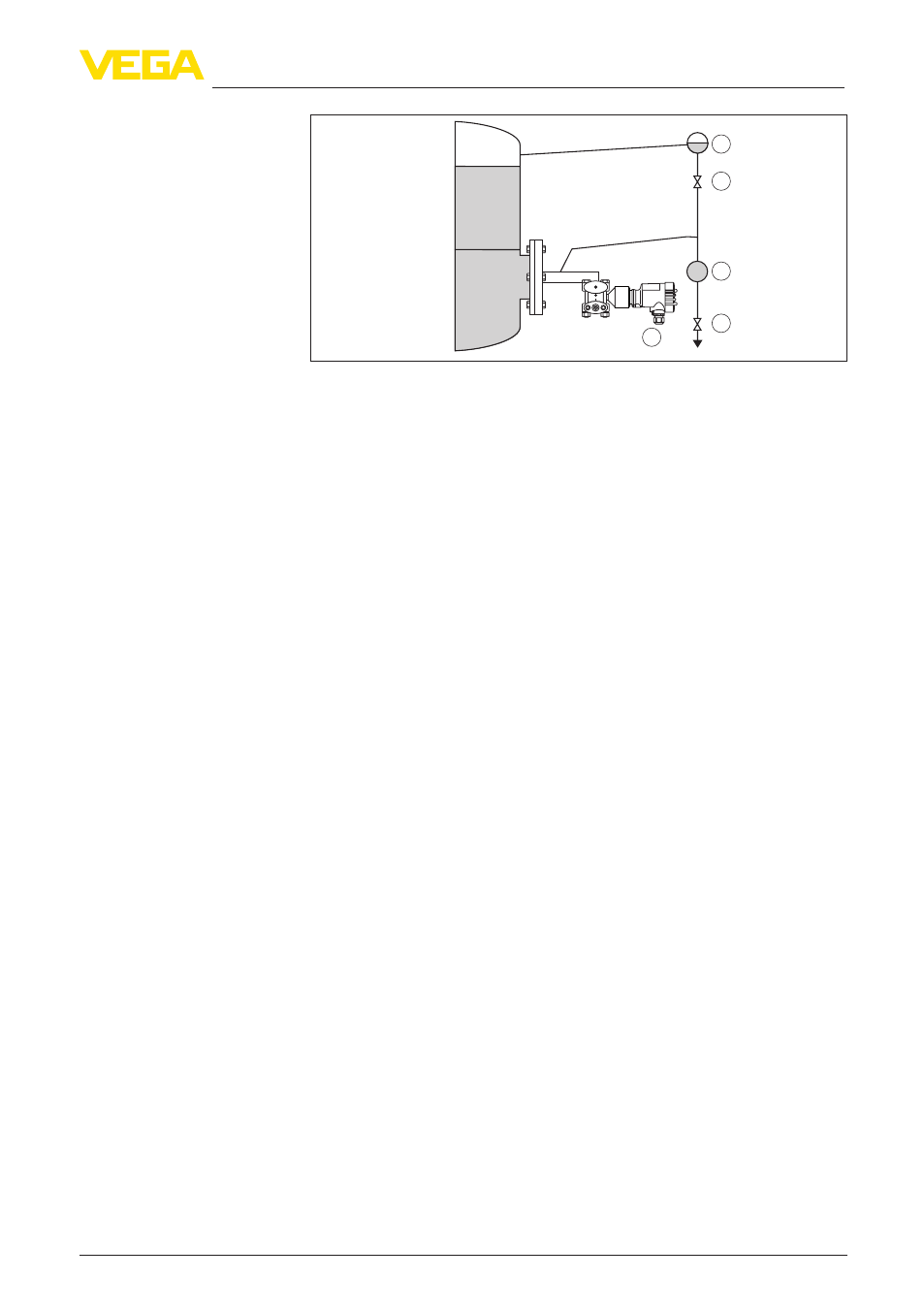

Fig. 26: Measurement setup in closed vessel with superimposed steam

1 Condensate vessel

2 Blocking valve

3 Separator

4 Drain valve

5 VEGADIF 65

4.6 Measurement setup density and interface

In a vessel with varying level and homogeneous density distribution,

density measurement with a differential pressure transmitter can be

realized. The connection to the vessel is made via a chemical seal on

two measuring points. To reach a high accuracy, the distance between

these points must be as big as possible. The density measurement is

only ensured with a level above the upper measuring point. If the level

drops below the upper measuring point, the density measurement is

interrupted.

This density measurement functions with open but also with closed

vessels. Make sure that small density changes cause only small

changes to the measured differential pressure. Select a suitable

measuring range.

The density measurement is carried out in the mode level measure-

ment.

1. Mount VEGADIF 65 below the lower chemical seal

2. The ambient temperature should be the same for both capillaries

Example for a density measurement:

Distance between the two measurement points: 0.3 m

Min. density: 1000 kg/m³

Max. density: 1200 kg/m³

Measured differential pressure: Δp = ρ • g • h

The min. adjustment is carried out for the differential pressure meas-

ured at density 1.0:

Δp = ρ • g • h

= 1000 kg/m³ • 9.81 m/s

2

• 0,3 m

= 2943 Pa = 29.43 mbar

Density measurement