VEGA VEGAMET 391 4 … 20 mA_HART User Manual

Page 46

46

8 Application examples

VEGAMET 391 • 4 … 20 mA/HART

36032-EN-130701

•

Measured value change higher: Measured value change per

time unit, at which the tendency recognition should respond

•

Max. reaction time: Time after which a new measured value

generation is carried out and the measured value change is

recalculated

•

Hysteresis: is automatically always 10 % of the value of "Meas-

ured value change larger than"

•

Reaction in case of failure: In case of a failure, the relay goes

into the defined condition

Note:

After switching on or a failure, always two complete cycles must be

executed until a measured value difference can be calculated and a

tendency can be outputted.

The level in a basin should be monitored on rising tendency. If the rise

is higher than 25 % per minute, an additional emptying pumpt should

be switched on. The max. reaction time should be one minute. In case

of a probable failure, the pump should be switched off.

Select in the DTM navigation section the menu items "Meas. loop -

Outputs - Relay".

•

E.g. set for relay 1 the mode "Rising tendency"

•

Select under "Reaction in case of failure" the option "Switching

condition off"

•

Enter the following values into the parameter fields:

– Measured value more than 25 %/min.

– Max. reaction time 1 min.

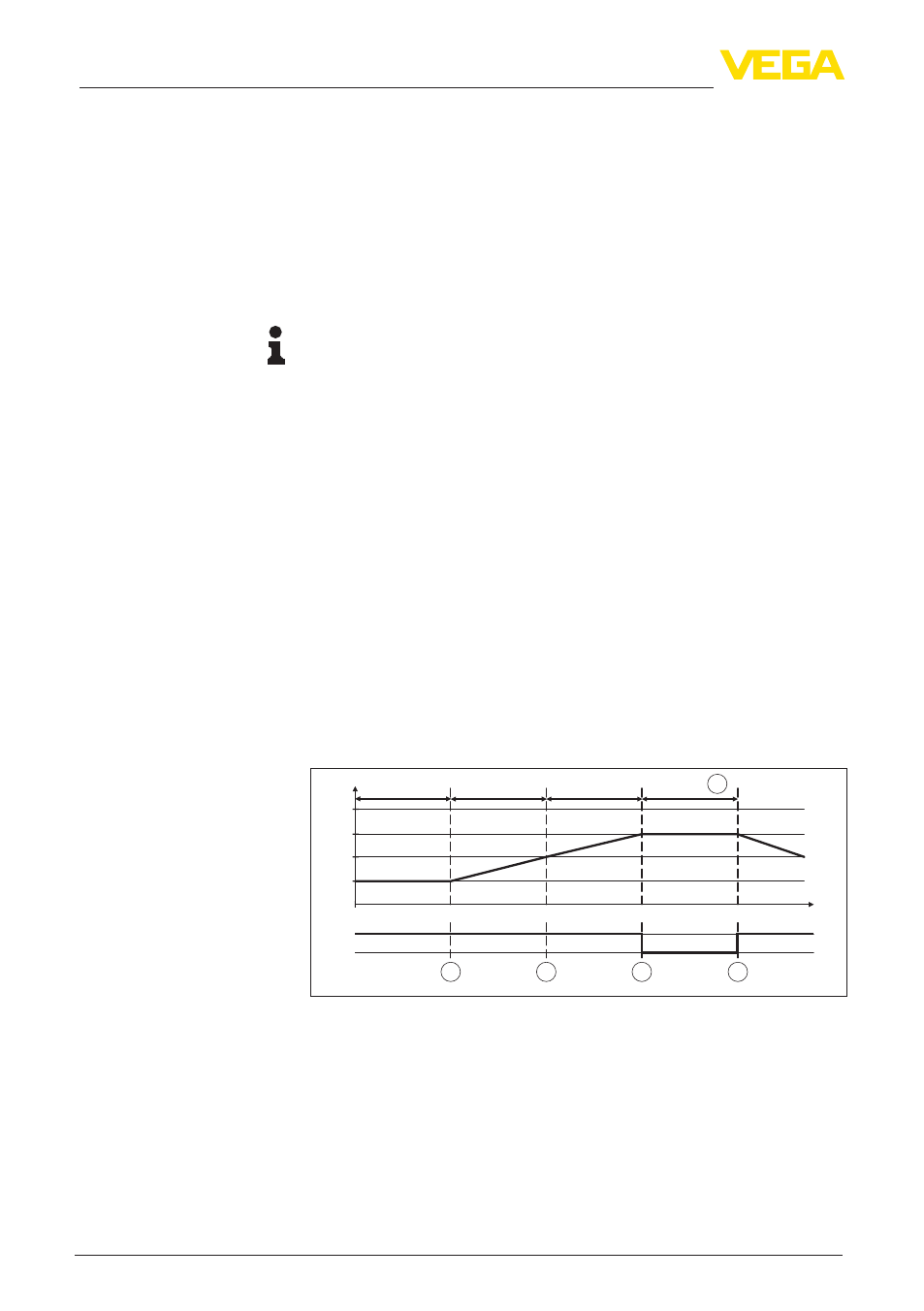

The function of the tendency recognition is shown in detail in the fol-

lowing diagram. The previously described example is used as a basis.

t

t

m

t

m

t

m

t

m

120

180

240

ON

OFF

60

[sec]

1

2

3

4

5

...

...

...

...

100

75

50

25

0

%

...

Fig. 18: Example for tendency recognition

1 Old average value = 25 %, new average value = 25 %

Difference < 25 % -> Relay ON

2 Old average value = 25 %, new average value = 37.5 %

Difference < 25 % -> Relay ON

3 Old average value = 37.5 %, new average value = 62.5 %

Difference = 25 % -> Relay OFF

4 Old average value = 62.5 %, new average value = 75 %

Difference < 25 % -> Relay ON

5 tm -> max. reaction time

Parameter

Example

Setup