VEGA VEGAMET 391 4 … 20 mA_HART User Manual

Page 41

41

8 Application examples

VEGAMET 391 • 4 … 20 mA/HART

36032-EN-130701

•

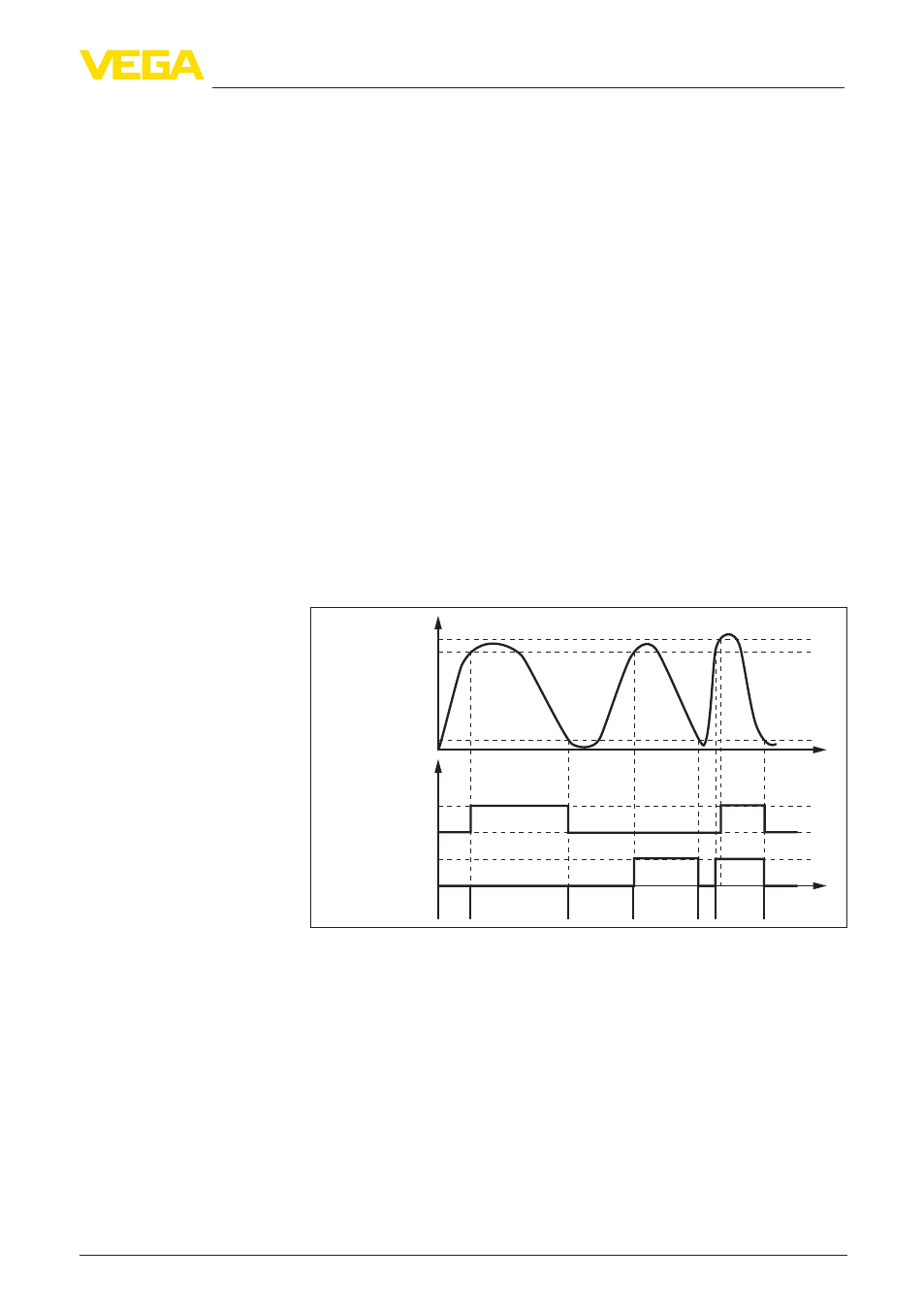

Pump control 1: The upper switching point determines the switch-

off point for the relay, whereas the lower switching point deter-

mines the switch-on point

•

Pump control 2: The upper switching point determines the switch-

on point for the relay, whereas the lower switching point deter-

mines the switch-off point

Two pumps should empty the vessel when a certain level is reached.

At 80 % filling, the pump with the shortest running time should switch

on. If the level nevertheless increases, a second pump should switch

on at 90 %. Both pumps should switch off again at 10 % filling.

Select in the DTM navigation section the menu items "Meas. loop -

Outputs - Relay".

•

Set mode "Pump control 2" for relay 1 and 2.

•

Enter the switching points for the affected relays as follows:

– Relay 1 upper switching point = 80.0 %

– Relay 1 lower switching point = 10.0 %

– Relay 2 upper switching point = 90.0 %

– Relay 2 lower switching point = 10.0 %

The function of pump control 2 is shown in detail in the following dia-

gram. The previously described example is used as a basis.

Rel. 1: 80% On

On

Off

Off

On

Rel. 2: 90% On

Rel. 1, 2: 10% Off

10

30

20

20

15

t [h]

5

Rel. 1

Rel. 2

Fig. 14: Example of pump control 2

When pump control is activated, the assigned relays and possible

pump malfunctions are also displayed in the measured value indica-

tion.

Example

Setup

Display indication