5 diagnostics, 1 maintenance, 2 failure rectification – VEGA VEGABAR 40 HART User Manual

Page 36: Fault signals, Troubleshooting

36

VEGABAR 40 (HART

®

)

Diagnostics

5 Diagnostics

5.1 Maintenance

VEGABAR process pressure transmitters are

maintenance-free.

5.2 Failure rectification

Fault signals

VEGABAR provides maximum reliability with

its self-test and continuous self-monitoring.

VEGABAR diagnostics distinguishes between

atypical process conditions and faults in the

VEGABAR.

Atypical process conditions

Exceeding or falling short of measuring

range limits (fault signal extinguishes when

the measured value is again in the measuring

range).

Failure in VEGABAR

Failure in the electronics, interference or

damage of the measuring cell.

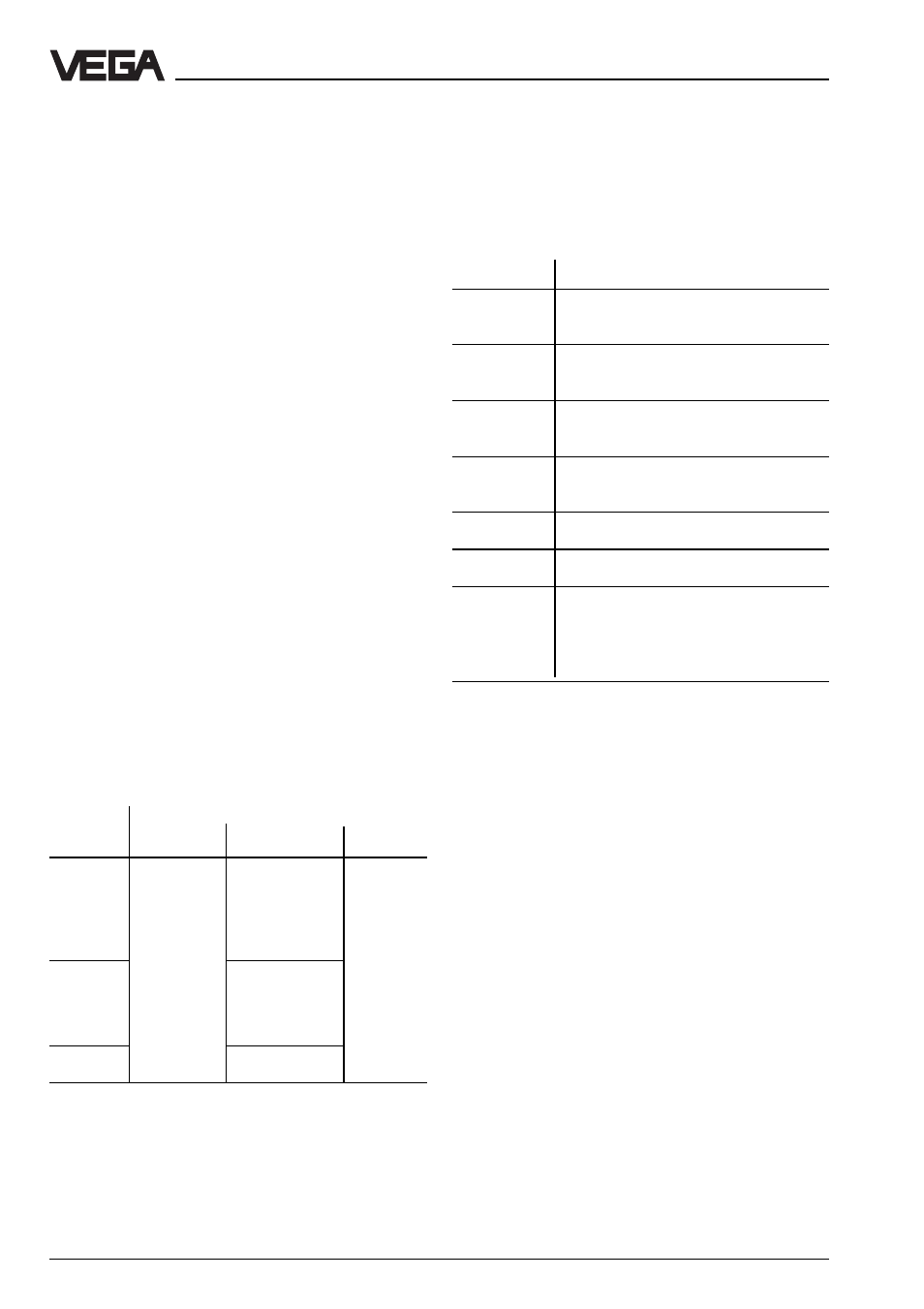

The following table assists in analysis of fault

signals.

Reason

Fault signal via

DOT-matrix

Bar graph

Current

Digital indication

output

Clearly

"OPERATE

Bar graph 0 %

outside

????

or 100 %

Current

measuring

bar“

digital value

value

range

flashes

3.6 mA

or

22 mA

Overload

Bar graph 0 %

range

or 100 %,

of the

digital value, four

meas. cell

flashing seg-

ments "- - - -“

Failure in

all segments

VEGABAR

flash

On instruments with menu-driven adjustment

with additional functions, the possible rea-

sons are displayed under the menu item

"Diagnostics no.“.

Diagnostics no.

Meaning

1

Connection to CID converter inter-

rupted

2

Frequency signal of the capacitor not

within the limit values

3

Frequency signal of the reference

capacitor not within the limit values

4

Frequency signal temperature not

within the limit values

7

Communication error to EEPROM

9

Error in EEPROM CRC-checksum

11

Process fitting or electronics unit has

been exchanged (appears for approx.

20 s after switching on for the first

time after the exchange)

Troubleshooting

If the displayed value does not correspond

to the level in the vessel or to the process

pressure, the following measures must be

taken:

- check the pressure compensation (only

with gauge pressure measuring ranges)

- check the electrical connection.