Moisture, Extracting forces, Pressure – VEGA VEGACAP 82-98 User Manual

Page 18: Aluminium vessel, Horizontal mounting

18

VEGACAP

Moisture

When mounting outside, on cooled vessels or

in humid areas where the cleaning is done,

e.g. with steam or high pressure, the sealing

of the cable entry is very important. Use

cable with sufficient conductor cross-section

and tighten the cable entry very securely. For

cables with insufficient conductor cross-

section, an appropriate reduction insert must

be used to ensure tightness.

Two different seal rings are attached to the

instrument to also enable reliable sealing of

cables with smaller diameter in the cable

entry. Use the smallest possible seal ring.

Turn the cable entries of the instrument down-

wards to avoid moisture ingress. For this

purpose the housing can be rotated by

approx. 330°. For vertically installed elec-

trodes loop the connection line to the instru-

ment housing downwards so that rain and

condensation water can drain off (see fig.

2.5).

Extracting forces

In case of strong extracting forces e.g. due

to material inflow, high tensile loads can be

caused.

In this case use for short meas. distances a

rod electrode, as generally a rod is more

stable. If due to the length or the installation

position a cable electrode should be neces-

sary, the electrode should not be fixed but

just provided with a gravity weight, as the

cable can more easily follow the product

movements. Make sure that the electrode

cable does not touch the vessel wall.

Fasten the gravity weight of VEGACAP 35

with a plastic cable.

Pressure

In case of excess or low pressure in the

vessel, the mounting boss must be sealed on

the housing. Use the attached seal ring.

Check whether the seal ring is resistant

against the medium.

Isolating measures such as e.g., the cover-

ing of the thread with Teflon tape, can inter-

rupt the necessary electrical connection in

metal vessels. In such case earth the elec-

trode with an additional cable connection to

the vessel.

Aluminium vessel

In case of Aluminium vessels, an electrode

with steel thread should be used. The combi-

nation Aluminium on Aluminium should be

avoided, as the thread "seizes“ and cannot

be removed after some time without damage.

Mounting

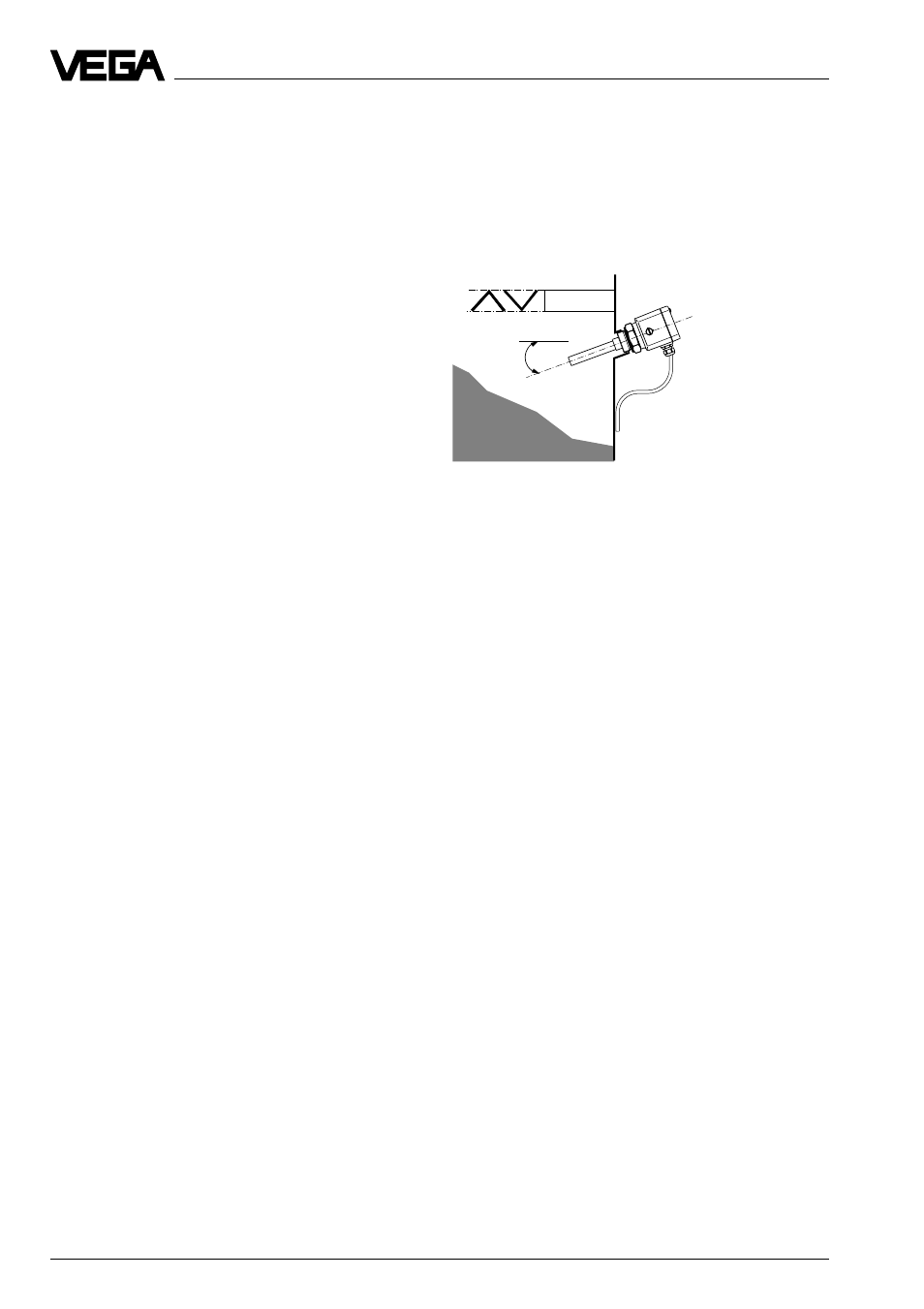

Horizontal mounting

The electrode can be mounted horizontally to

achieve an exact switching point for level

detection. We recommend mounting the

electrode approx. 20° inclined to the bottom

so that build-up is avoided (see fig. 2.4).

Fig. 2.4

20˚

1

0

a.

b.

Sheet