MSD 8356 Chevy V8 Dual Pickup Distributor Installation User Manual

Page 5

INSTALLATION INSTRUCTIONS

5

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

ADJUSTING THE SLIP COLLAR

Before installing the Pro-Billet Distributor, the slip collar adjustment must be set, follow this procedure.

1. Install the gasket on the housing then loosen the slip collar and insert the distributor into the engine

until it bottoms out against the oil pump drive.

2. After it bottoms out, raise the distributor 0.010" - 0.030" then slide the slip collar down into position

and tighten it.

CHECKING GEAR MESH

It is recommended to check for proper gear mesh between the cam gear and distributor gear. To

do this, coat the distributor gear with moly grease and install the distributor. Next, crank the engine

over several times. Before pulling the distributor out, make sure the rotor is in the position that lines

up with the original removal mark. Then pull the distributor out and inspect the gear pattern shown

on the grease. The proper mesh will leave an even pattern in the middle of the gear. Adjust the slip

collar to obtain the correct mesh.

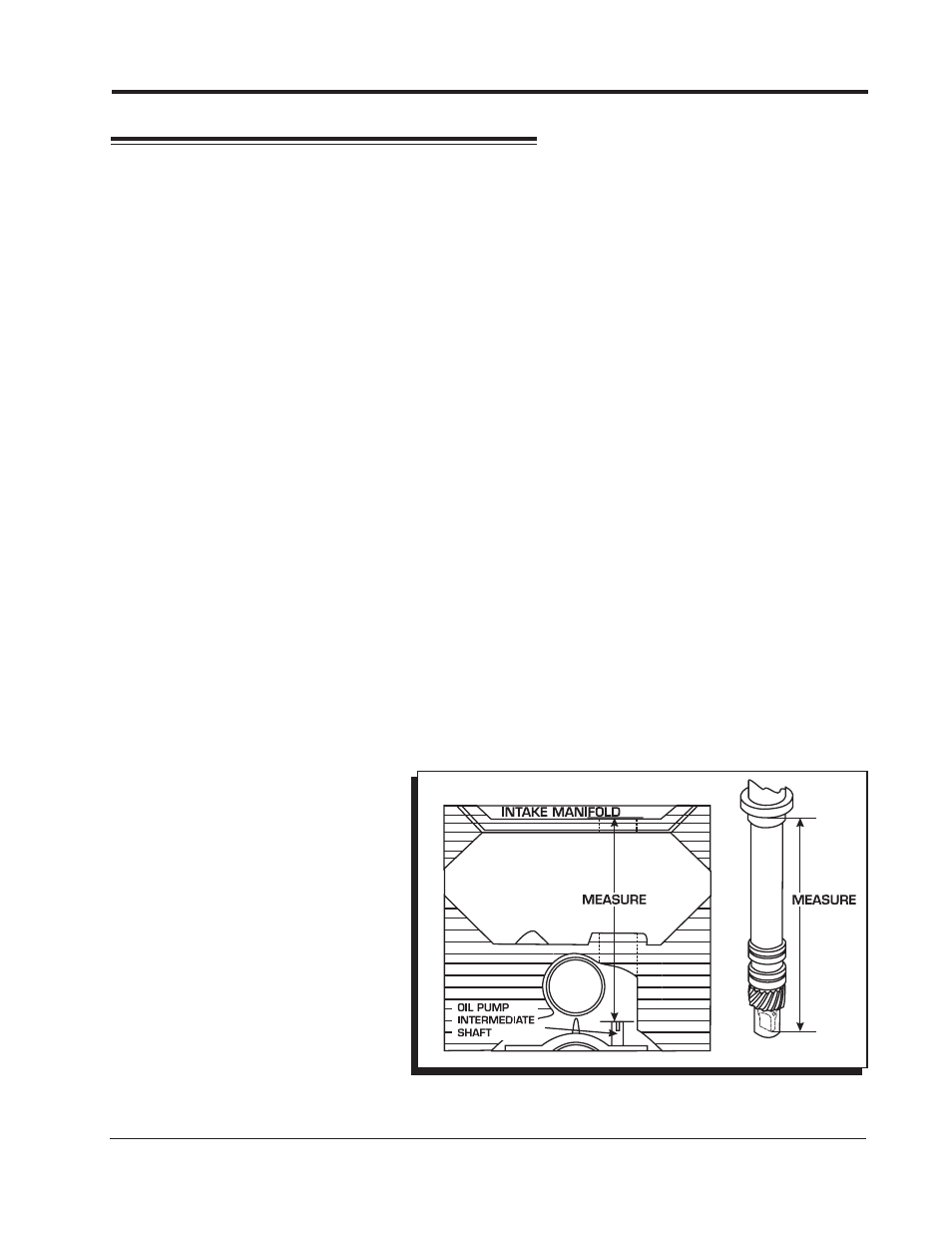

Checking the Oil Pump to Distributor Shaft Overlap

The proper overlap between the distributor shaft and the oil pump shaft is very important. The tongue of

the distributor shaft should fit into the groove of the oil pump shaft by at least 1/4". To check this:

1. Measure the distance between the base of the slip collar to the tip of the distributor shaft (Figure

8).

2. Using a straight edge, measure the distance from the intake manifold distributor flange to the top

of the oil pump intermediate shaft (Figure 8).

3. Take the two measurements and subtract them. The difference is the overlap. There must be at

least 1/4" of overlap. If there is not enough clearance or too much clearance, a different oil pump

intermediate shaft is required.

Figure 8 Measuring Oil Pump Shaft Overlap.