MSD 2922 Fuel Pump Return Kit Installation User Manual

Page 3

INSTALLATION INSTRUCTIONS

3

M S D

• W W W . A T O M I C E F I . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

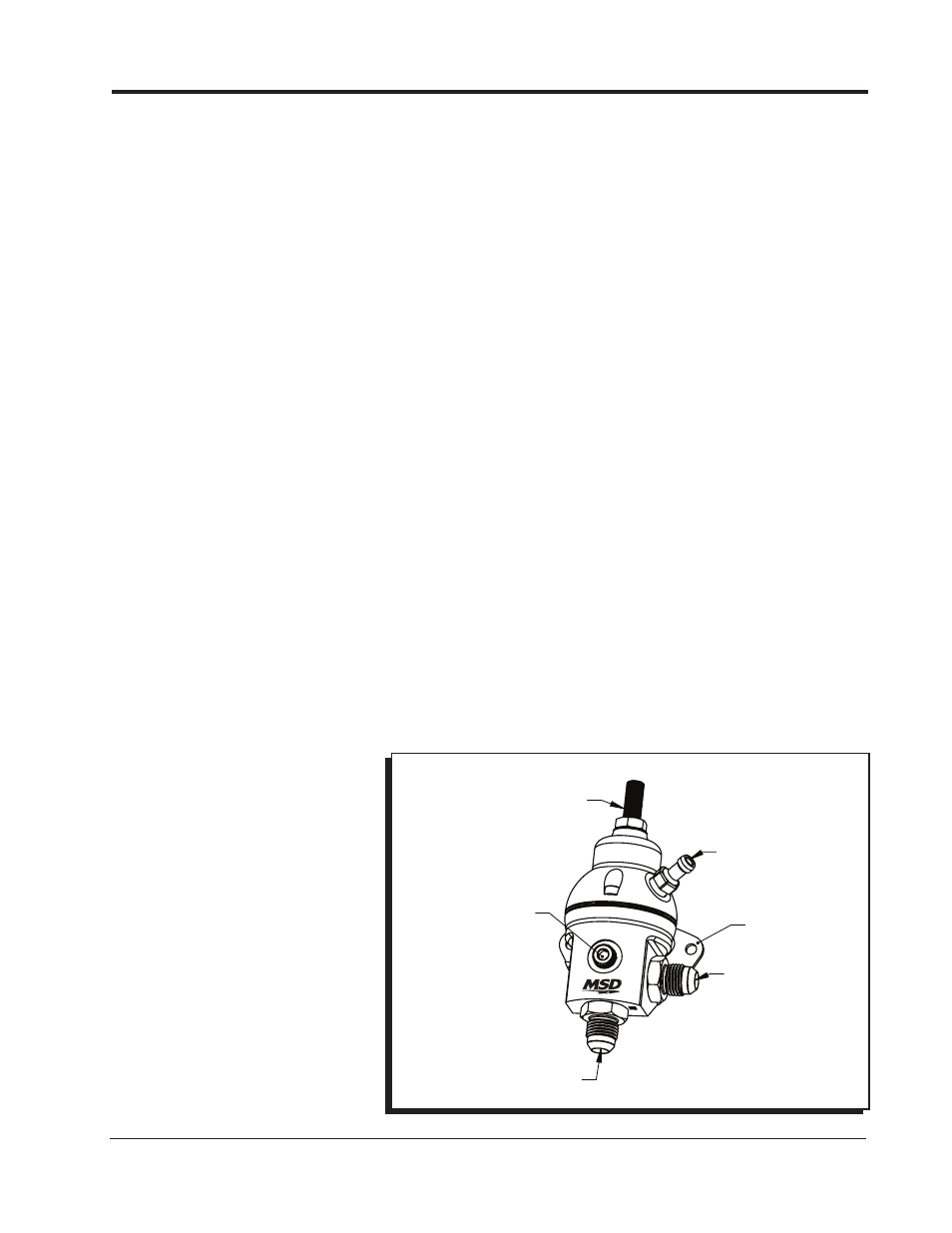

REGULATOR CONNECTIONS AND ADJUSTMENT

The regulator inlet port is located on the bottom surface, and clearly marked with an identifier machined

in the housing (see Figure 4 below). Two (2) outlet ports are available, but typically only one (1) will

be used. Install the supplied -6AN port plug in the unused outlet port using a 5/16-inch hex key (Allen

wrench). The -6AN straight port fittings should be snugged with an 11/16-inch wrench or deep socket.

Install the supplied 1/8-27 NPT brass hose barb fitting in the upper regulator housing (see Figure 4

below) using a 7/16-inch wrench or deep socket. Thread sealer is not required on this fitting, but

can be used if desired. Connect an intake manifold vacuum / boost source to this fitting, or leave

it open to the atmosphere if manifold pressure compensation is not required. DO NOT plug this

opening. Ensure that contaminants (such as water and road spray) cannot enter the open fitting.

In the event that vacuum / boost reference is not required, a more cosmetically pleasing option is to

install a sintered metal exhaust muffler in this port (such as McMaster-Carr PN 4450K1-Bronze or PN

4402K51-Stainless Steel)

The 1/8-27 NPT port in the lower housing allows the installation of a fuel pressure gauge (direct or

remote-reading). If use of this port is not required, install the supplied stainless steel pipe plug using

a 3/16-inch hex key (Allen wrench). Use of a fuel compatible paste-type thread sealer is REQUIRED

on this plug. Thread sealing tape is also an option, but not recommended due to the potential for

particulate and debris generation.

Use a 5/32-inch hex key (Allen wrench) to adjust the regulator set point. Clockwise rotation (screw

advancing inward) increases the set point, and counter-clockwise rotation (screw advancing outward)

decreases the set point. When the desired set point has been reached, snug the jam nut using a

½-inch wrench.

Refer to the user installation instructions, supplied with the Atomic EFI kit, for regulator set point

recommendations.

Note: An overly lengthy and restrictive return line routing scheme may result in a non-negligible

pressure rise across the regulator-to-tank portion of the system. For this reason, the final

regulator adjustment should be made while monitoring the system fuel pressure (on the Atomic

hand-held Dash) with the engine at idle.

Figure 4 - Regulator Feature Identification Guide

MOUNTING

BRACKET

VACUUM / BOOST

REFERENCE PORT

(1/8-27 NPT)

OUTLET PORT

(1 OF 2)

ADJUSTMENT SCREW

AND LOCK NUT

INLET PORT

GAUGE PORT

(1/8-27 NPT)