Regulator mounting – MSD 2922 Fuel Pump Return Kit Installation User Manual

Page 2

2

INSTALLATION INSTRUCTIONS

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

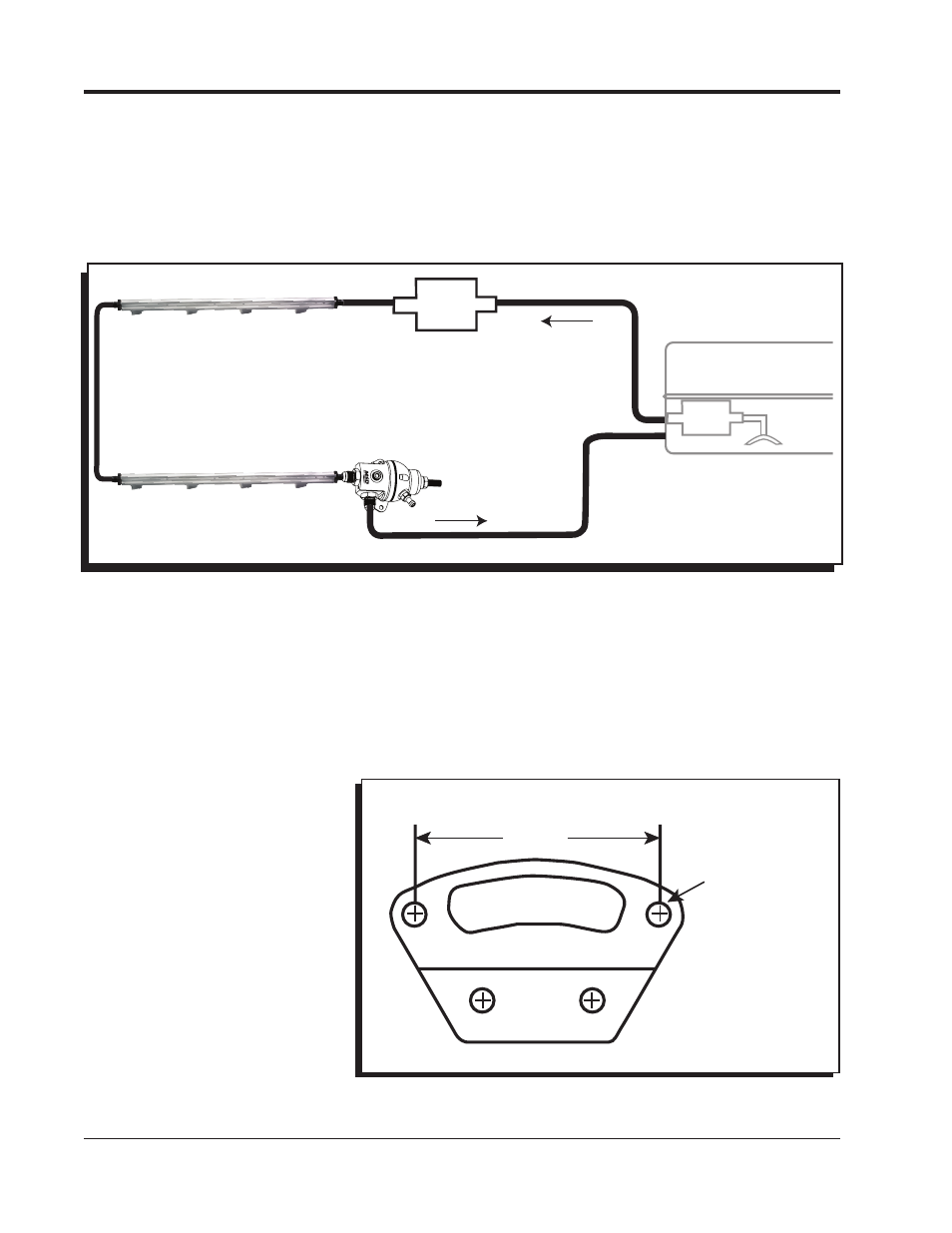

Use the schematic below as a guide when installing the kit in conjunction with an Atomic LS EFI system.

There are two possible connection points (one at the rear of each fuel rail assembly). One rail will be

connected to the fuel supply in an operational system. DO NOT “tee” into the supply line and leave

the opposing fuel rail plugged or capped. Fuel from the opposing rail should be routed to the regulator

inlet port (using the supplied hose and fittings). The hose length between the rail and regulator is not

critical, but generally speaking, should be kept to a minimum. Route and secure the hose as necessary

to prevent chafing, stretching due to engine movement, and heat-related damage.

Figure 3 Regulator Mounting Bracket Template

FUEL

FILTER

FUEL TANK

FUEL

PUMP

IT IS RECOMMENDED TO MOUNT

THE FUEL PUMP IN THE TANK

WHENEVER POSSIBLE. IF IT MUST

BE MOUNTED EXTERNALLY, MOUNT

THE PUMP WITHIN 2-FEET OF THE

FUEL TANK SENDING UNIT.

FUEL RAIL

(UNDER COVER)

FUEL RAIL

(UNDER COVER)

FUEL RAIL

(UNDER COVER)

MSD ADJUSTABLE

REGULATOR

Figure 2 Atomic LS Return Fuel System.

The regulator-to-tank connection should be made using the supplied hose and fittings. Install the

supplied -6AN port plug in whichever regulator return port is not used. Depending on the configuration

of your fuel tank / fuel cell, the supplied high pressure fuel hose clamp may be used at the tank fitting

connection.

Use care when routing the hose from the regulator to the tank. Route and secure the hose as necessary

to prevent chafing, stretching due to engine movement, and heat-related damage.

REGULATOR MOUNTING

Using the two (2) supplied 10-32

x 0.375 Button Head Cap Screws

and a 1/8-inch hex key (Allen

wrench), attach the regulator

bracket to the regulator body. The

regulator may then be mounted

to the firewall, or other convenient

surface. Regulator orientation

is not critical, but be mindful of

adjustment screw access and hose

routing. Refer to Figure 3 for a

mounting bracket template.

2.200”

ACCOMMODATES

#10 SCREW