Assembly – Bosch GGS 6 S Professional User Manual

Page 16

16 | English

1 619 929 K88 | (26.4.12)

Bosch Power Tools

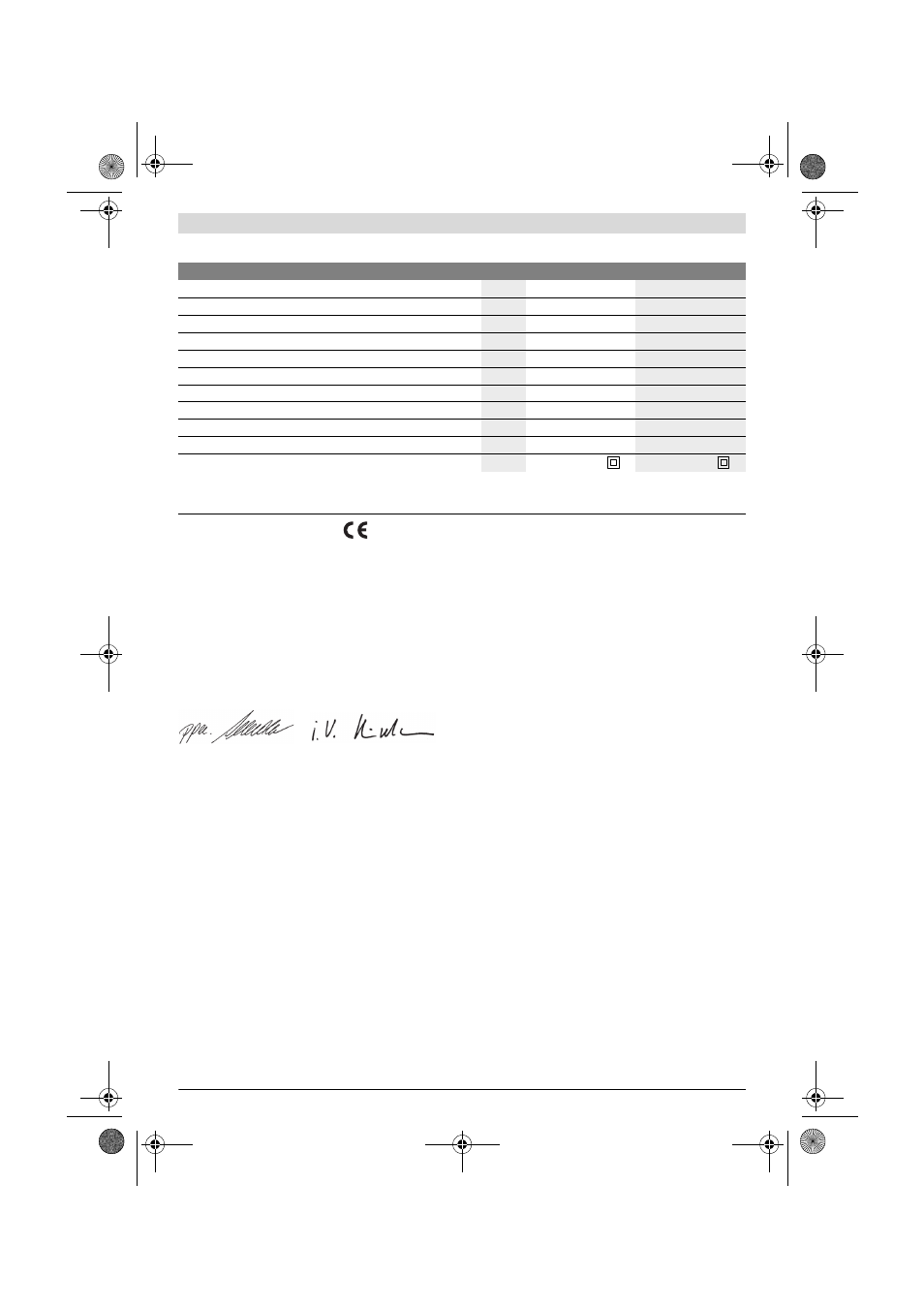

Technical Data

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical Data” is in conformity with the fol-

lowing standards or standardization documents: EN 60745

according to the provisions of the directives 2011/65/EU,

2004/108/EC, 2006/42/EC.

Technical file (2006/42/EC) at:

Robert Bosch GmbH, PT/ETM9,

D-70745 Leinfelden-Echterdingen

Robert Bosch GmbH, Power Tools Division

D-70745 Leinfelden-Echterdingen

28.03.2012

Assembly

f

Before any work on the machine itself, pull the mains

plug.

Mounting the Protective Devices

f

Adjust protection guards in such a manner that spark-

ing toward the operator is prevented.

Protection Guard for Grinding (GGS 6 S) (see figure A)

Place the protection guard 2 on the spindle collar. Adapt the

position of the protection guard 2 to the requirements of the

work step. Lock the protection guard 2 with locking screw 14

and tighten the locking screw with at least 10 Nm.

Protection Guard for Grinding (GGS 6) (see figure E)

Place the protection guard 11 on the spindle collar. Adapt the

position of the protection guard 11 to the requirements of the

work step. Lock the protection guard 11 with the two locking

nuts 19 and tighten the locking nuts with at least 10 Nm.

After mounting the grinding tool, shut the protection guard 11

and tighten both wing nuts.

Mounting the Grinding Tools

The grinding tools must run completely concentrically. Do not

continue to use damaged grinding tools that are out of bal-

ance. If the grinding tools are out of balance they should be re-

placed. Treat with a whetstone (accessory) or change.

Using a whetstone, any particular special shape can be pro-

duced out of the basic forms of the grinding accessory.

When using grinding tools with a threaded insert, pay atten-

tion that the end of the grinder spindle 3 does not touch the

hole base of the grinding tool.

GGS 6 S (see figure B)

– Turn the grinder spindle 3 until the hole in the grinder spin-

dle 3 and the openings of the housing are aligned. Insert

the holding rod 15 through the openings of the housing

and the hole of the grinder spindle 3.

– Loosen and remove the clamping nut 1 with the two-pin

spanner 16 provided.

– Clean the grinder spindle 3 and all parts to be mounted.

– Mount the grinding accessory and tighten clamping nut 1

with two-pin spanner 16. Pay attention that the grinding

accessory can rotate freely in protection guard 2.

f

Use tapered grinding accessories only in conjunction

with the open protection guard 2 and the matching

clamping system (clamping nut 1 and mounting flange

4).

GGS 6 (see figure F)

– Turn the grinder spindle 3 until the hole in the grinder spin-

dle 3 and the openings of the housing are aligned. Insert

the holding rod 15 through the openings of the housing

and the hole of the grinder spindle 3.

– Loosen the clamping nut 9 with the open-end spanner 20

(size 24 mm) by turning in anticlockwise direction.

– Remove the clamping flange 10.

– Clean the grinder spindle 3 and all parts to be mounted.

Straight grinder

GGS 6

GGS 6 S

Article number

0 601 214 0..

0 601 214 1..

Rated power input

W

1200

1150

Output power

W

720

670

Max. speed

min

-1

6800

6800

Thread of grinder spindle

5/8"

M 14

Max. spindle length

mm

27

31

Tool holder

mm

16

20

Max. grinding disc thickness

mm

25

32

Grinding tool diameter, max.

mm

125

125

Weight according to EPTA-Procedure 01/2003

kg

3.9

3.9

Protection class

/II

/II

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Starting cycles generate brief voltage drops. Interference with other equipment/machines may occur in case of unfavourable mains system conditions.

Malfunctions are not to be expected for system impedances below 0.36 ohm.

Dr. Egbert Schneider

Senior Vice President

Engineering

Helmut Heinzelmann

Head of Product Certification

PT/ETM9

OBJ_BUCH-1050-004.book Page 16 Thursday, April 26, 2012 10:22 AM