Phasing, Blower rotation, Belt tension – York PREDATOR 150 User Manual

Page 24: 22 belt adjustment, 16 supply air limitations

035-17311-002-A-0803

24

Unitary Products Group

PHASING

Predator

®

units are properly phased at the factory. Check for

proper compressor rotation. If the blower or compressors

rotate in the wrong direction at start-up, the electrical connec-

tion to the unit is misphased. Change the phasing of the Field

Line Connection at the factory or field supplied discon-

nect to obtain proper rotation. (Scroll compressors operate in

only one direction. If the scroll is drawing low amperage, has

similar suction and discharge pressures, or producing a high

noise level, the scroll is misphased.)

BLOWER ROTATION

Check for proper supply air blower rotation. If the blower is

rotating backwards, the line voltage at the unit point of power

connection is misphased (See ‘PHASING’).

BELT TENSION

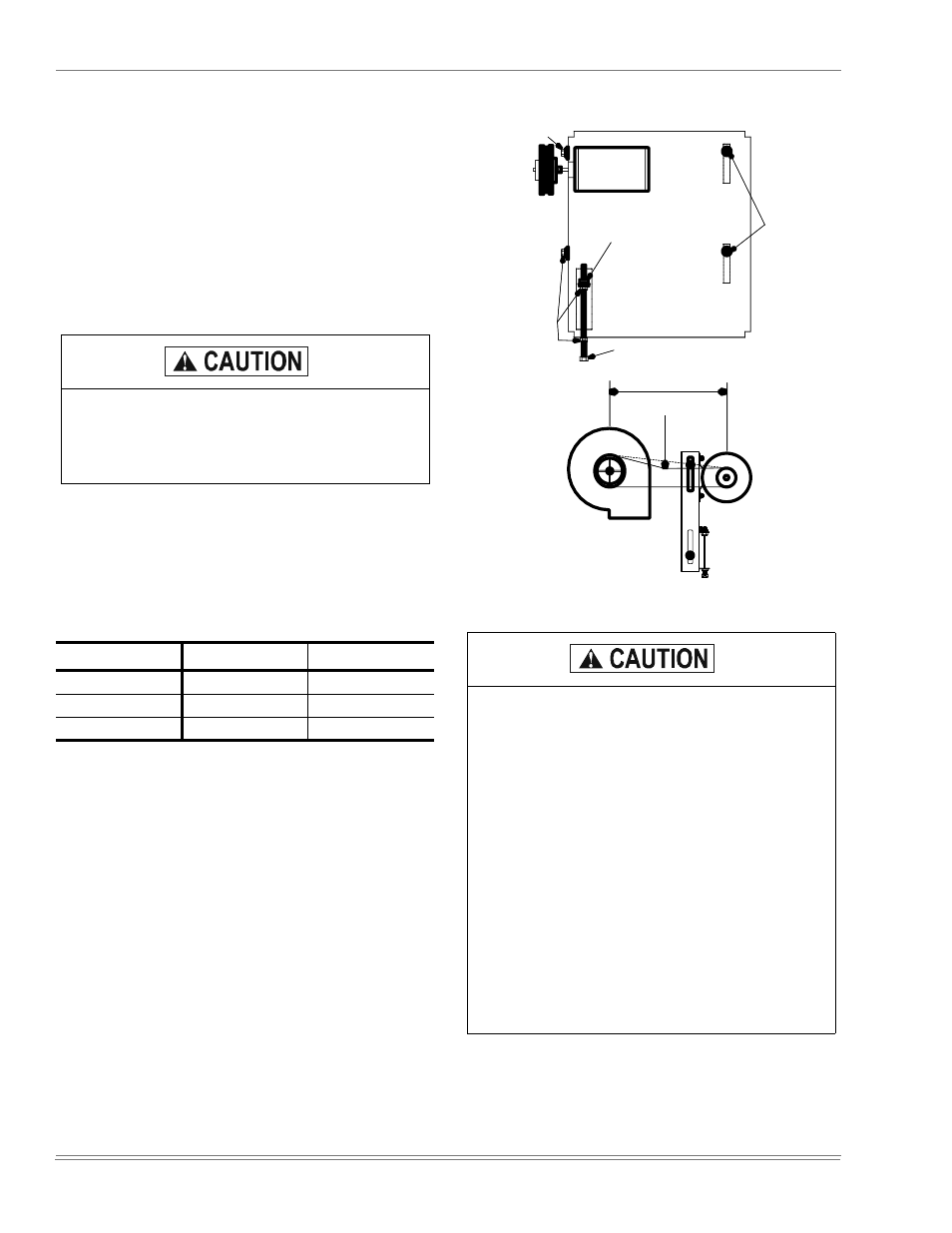

The tension on the belt should be adjusted as shown in

Figure 22.

Scroll compressors require proper rotation to oper-

ate correctly. Units are properly phased at the fac-

tory. Do not change the internal wiring to make the

blower condenser fans, or compressor rotate cor-

rectly.

TABLE 16: SUPPLY AIR LIMITATIONS

Unit Size

Minimum

Maximum

090

2250

3750

120

3000

5000

150

3750

6250

FIGURE 22 - BELT ADJUSTMENT

Procedure for adjusting belt tension:

1. Loosen six nuts (top and bottom) A.

2. Adjust by turning (B).

3. Never loosen nuts (C).

4. Use belt tension checker to apply a perpendicular

force to one belt at the midpoint of the span as

shown. Deflection distance of 4mm (5/32”) is

obtained.

To determine the deflection distance from normal

position, use a straight edge from sheave to sheave

as reference line. The recommended deflection

force is as follows:

Tension new belts at the max. deflection force rec-

ommended for the belt section. Check the belt ten-

sion at least two times during the first 24 hours of

operation. Any retensioning should fall between the

min. and max. deflection force values.

5. After adjusting retighten nuts (A).

A

A

A

B

SPAN LENGTH

DEFL. FORCE

C*

* NEVER LOOSEN