York PREDATOR DR120 User Manual

Page 55

127878-YIM-B-0606

Unitary Products Group

55

GAS VALVE

The UCB and ICB continuously monitor the GV.

If the ICB senses voltage at the GV when not requested, the

ICB will energize the draft motor. The ICB will not operate the

furnace until voltage is no longer sensed at the GV. The draft

motor is stopped when voltage is not sensed at the GV.

Any time the UCB senses voltage at the GV without a call for

heat for a continuous five-minute period, the UCB will lock-on

the indoor blower and a flash code is initiated (Table 41).

When voltage is no longer sensed at the GV, the UCB will de-

energize the indoor blower following the elapse of the fan off

delay for heating.

If voltage has been sensed at the GV for at least 15 seconds

during the fan on delay for heating and GV voltage or “W1” is

lost, the indoor blower is forced on for the length of the fan off

delay for heating.

During a call for heat, if the UCB does not sense voltage at

the GV for a continuous five-minute period the UCB will ini-

tiate a flash code (Table 41). The indoor blower motor will not

be locked-on while there is no GV voltage.

SAFETY CONTROLS

The UCB monitors the temperature limit switch of gas heat

units.

The control circuit includes the following safety controls:

LIMIT SWITCH (LS)

This control is located inside the gas heat compartment and

is set to open at the temperature indicated in the Gas Heat

Limit Control Settings Table 37. It resets automatically. The

limit switch operates when a high temperature condition,

caused by inadequate supply air flow occurs, thus shutting

down the heater and energizing the blower.

AUXILIARY LIMIT SWITCH (ALS)

This control is located inside the supply air compartment and

is set to open at the temperature indicated in the Gas Heat

Limit Control Settings Table 37. It resets manually. The limit

switch operates when a high temperature condition, caused

by inadequate supply air flow occurs, thus shutting down the

heater and energizing the blower.

The auxiliary limit switch is wired in series with the limit

switch. As such, the UCB cannot distinguish the auxiliary limit

and the gas heat limit switch operation except the auxiliary is

manual reset. Consequently, the control will respond in the

same manner as outlined above under “Limit Switch”.

The ICB monitors the Pressure and Rollout switches of gas

heat units.

The control circuit includes the following safety controls:

PRESSURE SWITCH (PS)

Once the draft motor has reached full speed and closes the

pressure switch during a normal ignition sequence, if the

pressure sw opens for 2 seconds, the GV will be de-ener-

gized, the ignition cycle is aborted, and the ICB flashes the

appropriate code. See Table 42 Ignition Control Flash Codes.

The draft motor is energized until the pressure switch closes

or “W1” is lost.

ROLLOUT SWITCH (ROS)

The rollout switch is wired in series with the pressure switch.

As such, the ICB cannot distinguish the rollout switch opera-

tion from that of the pressure switch.

Consequently, the control will only respond in the same man-

ner as outlined above under “Pressure Switch”. An open roll-

out will inhibit the gas valve from actuating.

INTERNAL MICROPROCESSOR FAILURE

If the ICB detects an internal failure, it will cease all outputs,

ignore inputs, and display the proper flash code for control

replacement. The ICB remains in this condition until replaced.

FLASH CODES

The UCB will initiate a flash code associated with errors

within the system. Refer to UNIT CONTROL BOARD FLASH

CODES Table 41.

RESETS

Remove the call for heating by lowering the thermostat set-

ting lower than the conditioned space temperature. This

resets any flash codes.

GAS HEAT ANTICIPATOR SETPOINTS

It is important that the anticipator setpoint be correct. Too

high of a setting will result in longer heat cycles and a greater

temperature swing in the conditioned space. Reducing the

value below the correct setpoint will give shorter “ON cycles

and may result in the lowering of the temperature within the

conditioned space. Refer to Table 38 for the required gas

heat anticipator setting.

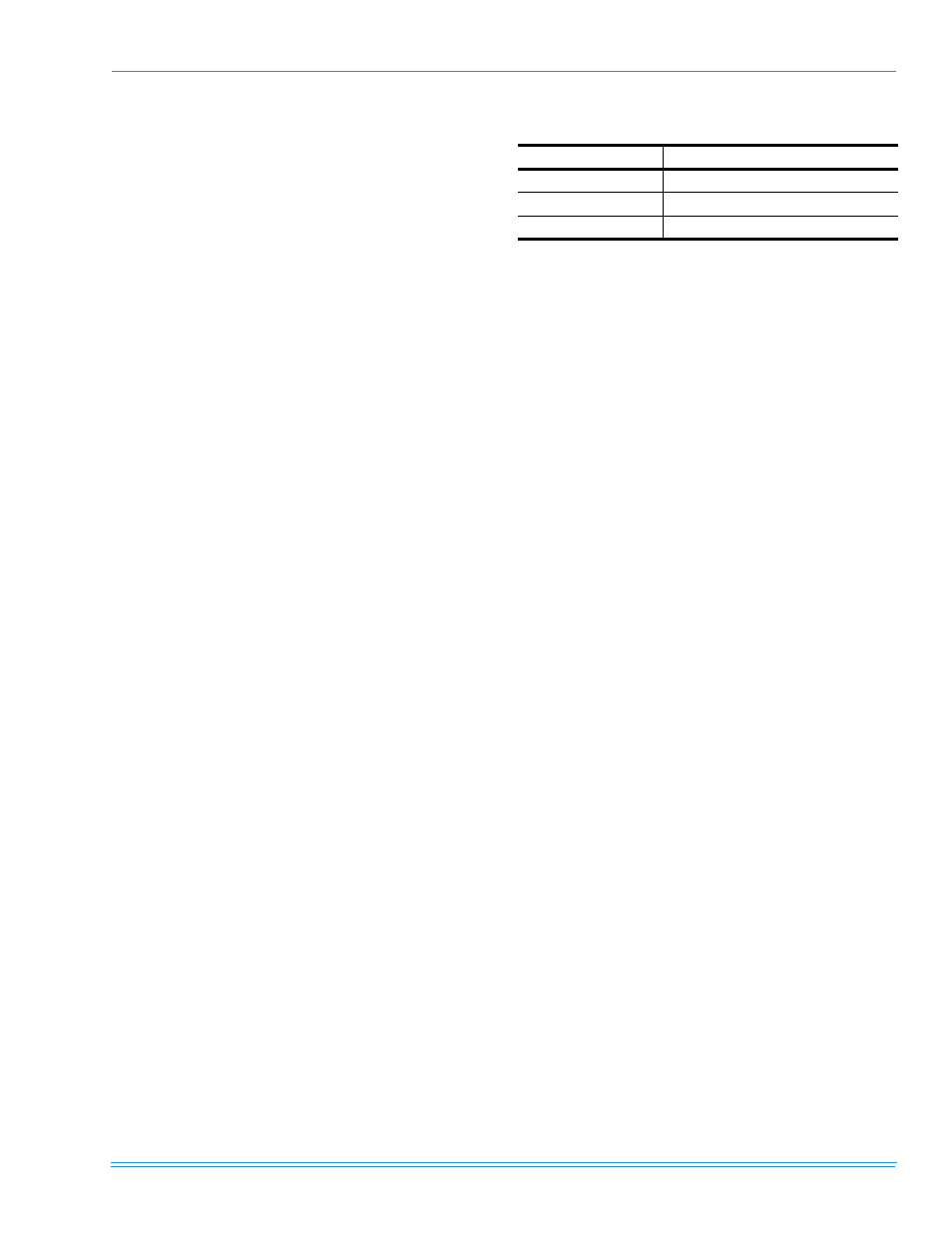

TABLE 37: GAS HEAT LIMIT CONTROL SETTINGS

*

*.

Rollout = 300°F, Auxiliary Limit = 200°F.

# of HX Tubes

Main Limit Setting

4

215°F

6

195°F

8

160°F