Refrigerant piping connections, Fixing and piping, Maximum piping length – York YUHC 18-60 User Manual

Page 15

15

ENGLISH

■

Fixing and Piping

• Piping must be performed by qualified personnel

according to good refrigeration system practices.

• Piping materials and insulation materials must be of

refrigerant quality.

• Select the pipe diameters according to the size of

unit and cut the pipe to design length by using pipe

cutter.

• Install the flare nuts and flare the end of the pipes.

• Check that no foreign bodies are inside the piping.

• Align the central of the connection pipes and tighten

the flare nut.

• Fix piping with pipe clamps and check that any pipe

vibrations cannot be transmitted to the building

structure.

• Connect the pipe correctly.

• Do not apply the excessive torque.

• Use an appropriate bending tool to form curves and

avoid over-tightening the refrigerant tubes.

• To prevent heat loss, the two lines must be insulated

separately.

■

Maximum Piping Length

The suction line must have a 2% gradient up to the

compressor on horizontal sections.

Where piping lengths are unusually long and include a

large number of oil traps, it may be necessary to adjust

to compressor charge.

NOTES

Unit size

18

24

30

36

48

60

(m)

30

30

30

30

30

30

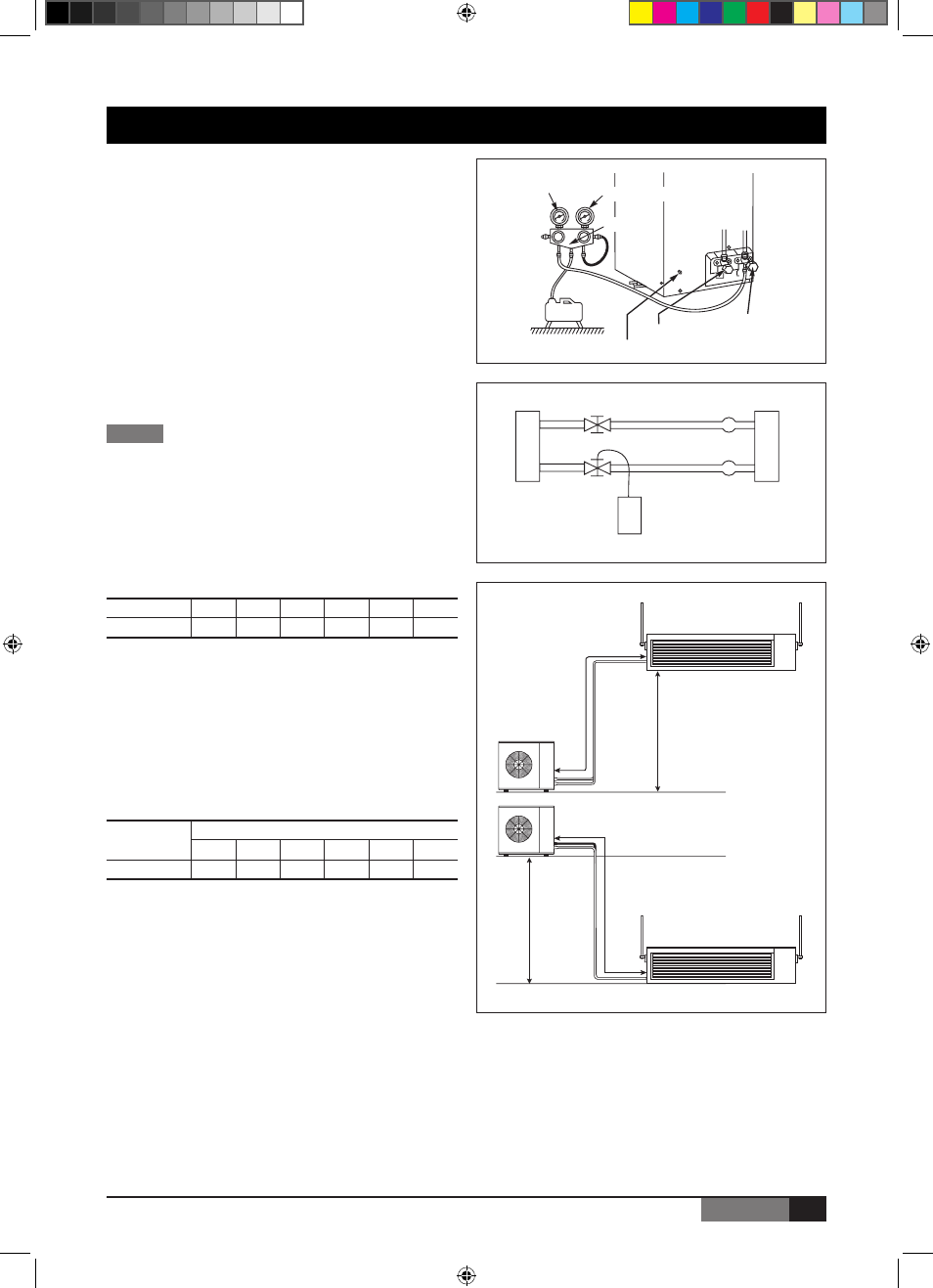

REFRIGERANT PIPING CONNECTIONS

■

Refrigerant charge to be added per extra

meter of piping length when more than 5

meters.

Prefabricated refrigerant piping is available as an acces-

sory. If this is not used, piping and insulating materials

employed must be compatible with this type of installa-

tion.

The pre-charged outdoor unit does not require charging

if piping length is 5 m or less. However, the interconnect-

ing piping and the indoor unit must be pumped down

before releasing R-410A refrigerant into them from the

outdoor unit.

1. Remove the cap from the service valve.

2. Connect the line to a vacuum pump and pump

down to 5 Pa.

3. When pump down is finished, wait 15 minutes

to detect potential circuit leakage. Open service

valves on the outdoor unit.

Outdoor unit

Indoor unit

Gas line

Liquid line

R-410A

*

Note: The expansion device is located in the outdoor unit.

High pressure

Pressure tap

Manifold

Low pressure

Liquid valve

Gas valve

L

D

L

H

Unit size

Models

18

24

30

36

48

60

(g/m)

30

65

90

90

90

90

J368-EN.indd 15

2/1/07 9:41:19 AM